GEHO and method for mounting inlet valve chamber thereof

An installation method and inlet valve technology are applied to parts, pumps, and pump components of pumping devices for elastic fluids, which can solve problems such as potential safety hazards, reduced service life of four screw rods 6, and breakage, and achieve the elimination of safety hazards. Hidden dangers, the effect of solving screw breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the drawings.

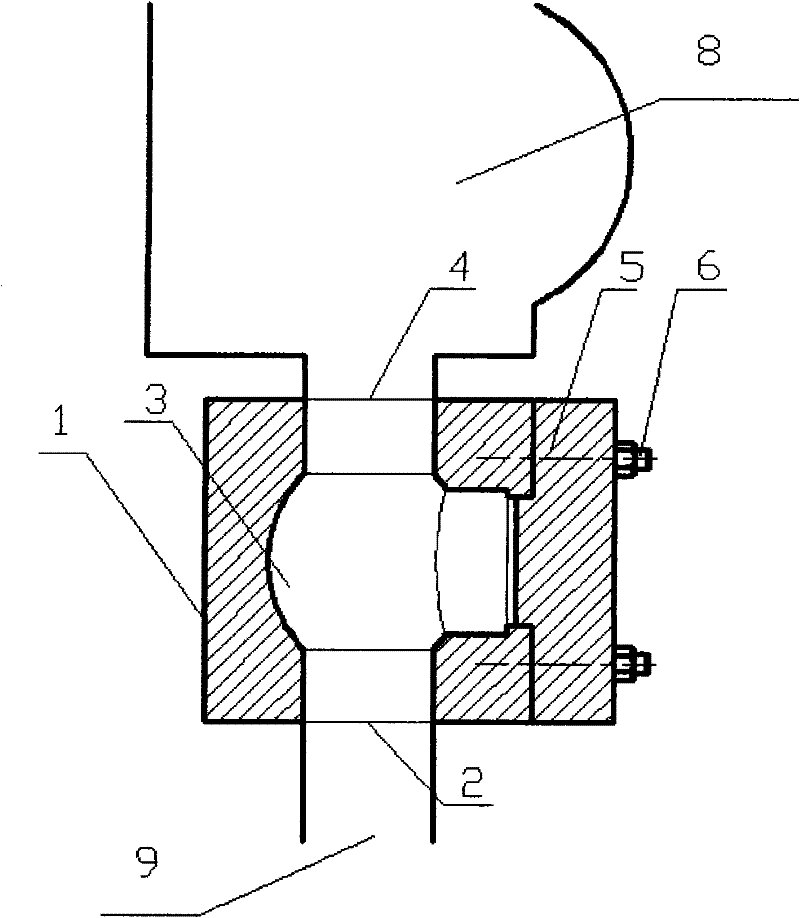

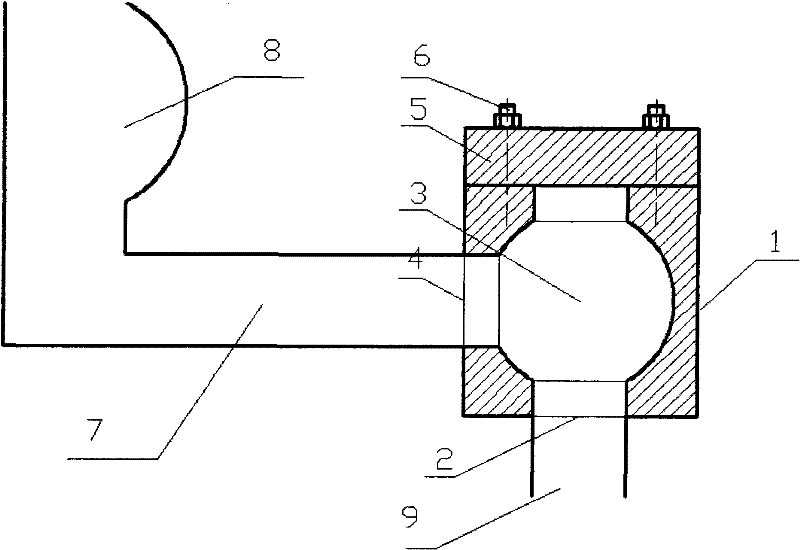

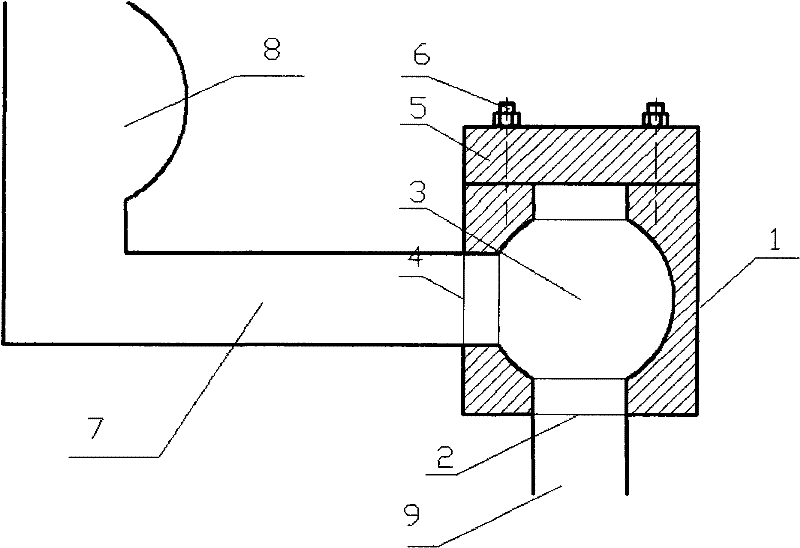

[0019] Such as figure 2 As shown, the valve chamber outlet 4 is arranged on the side of the valve chamber 1, and the valve chamber outlet 4 is connected to the inlet of the diaphragm chamber 8 through a 90° elbow, so that the connection between the diaphragm chamber 8 and the valve chamber outlet 4 is vertical to The connection on the same line is converted into a 90° included angle connection, so that the end cover 5 can be vertically installed on the upper part of the valve chamber 1 in a manner that can move in the vertical direction, so that the screw 6 that fixes the end cover is also A vertical installation is formed, so that the slurry inlet 2 of the chamber 3 in the valve chamber and other parts in the valve chamber do not need to be changed, just replace the slurry outlet 4 of the valve chamber on the side of the valve chamber 1. . In this way, during the operation of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com