Combination cubic socket

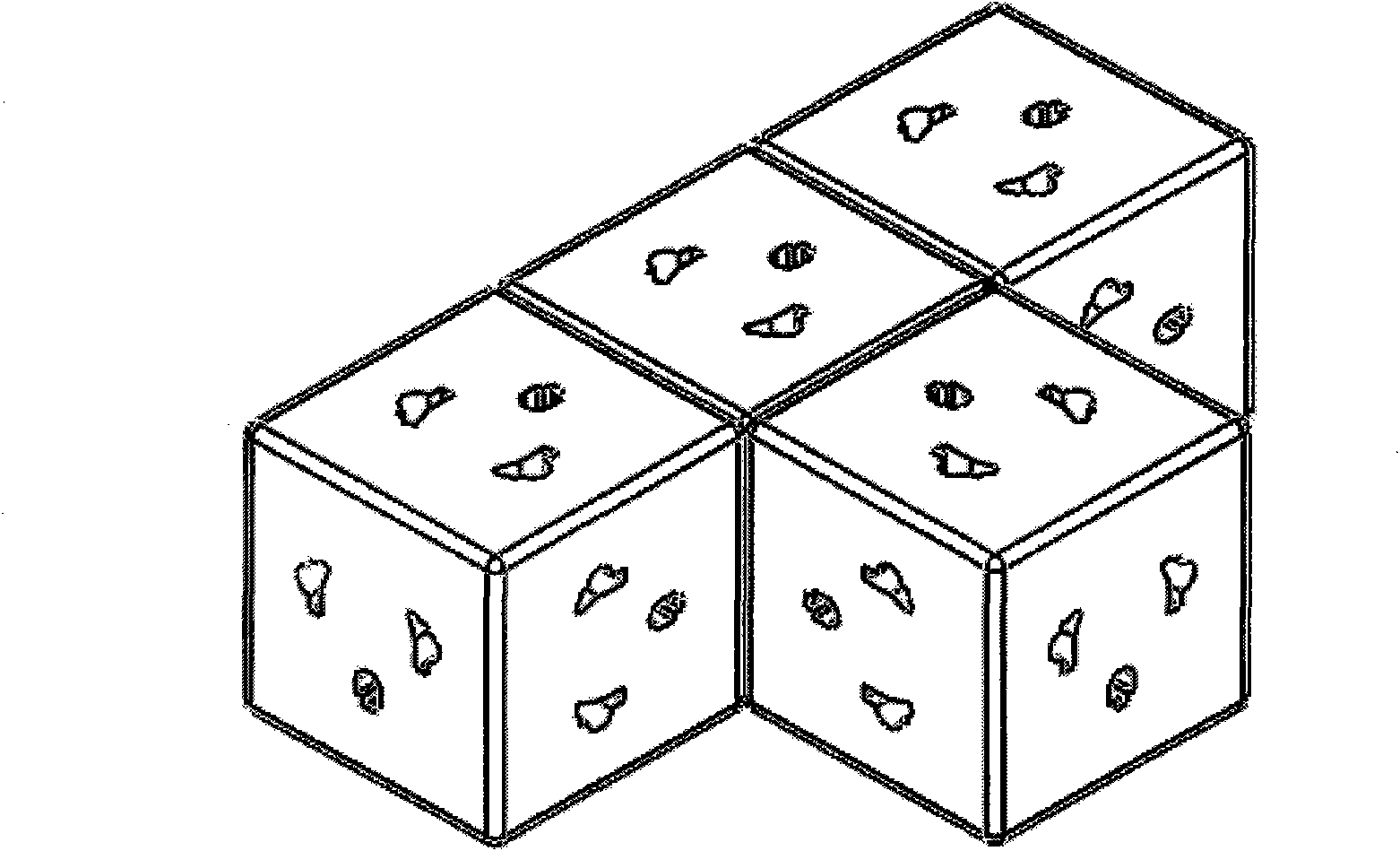

A cube and socket technology, applied in coupling devices, contact parts, electrical components, etc., can solve the problems of space waste, large socket size, and socket utilization problems, and achieve good portability, compact overall structure, and simplified internal structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

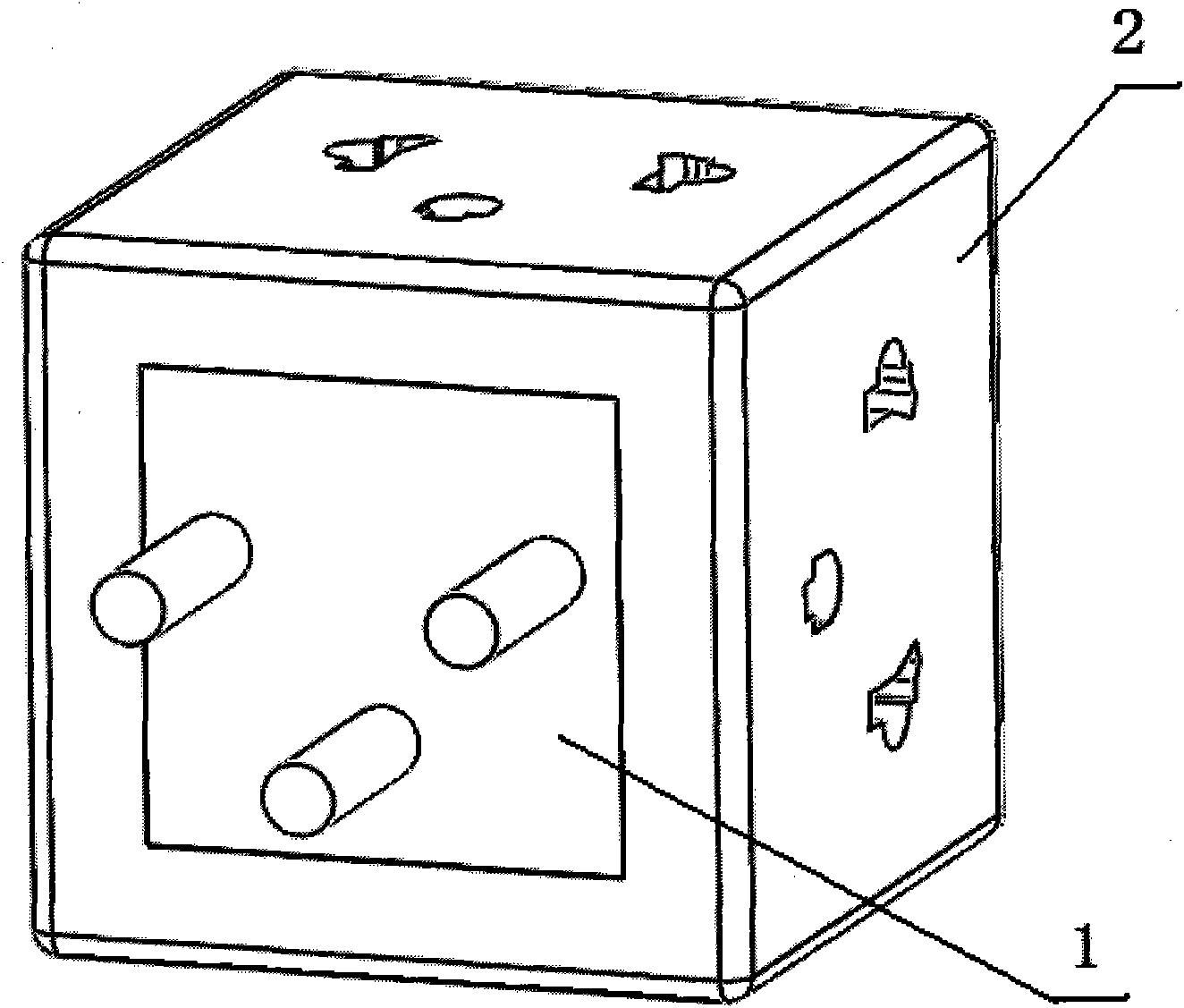

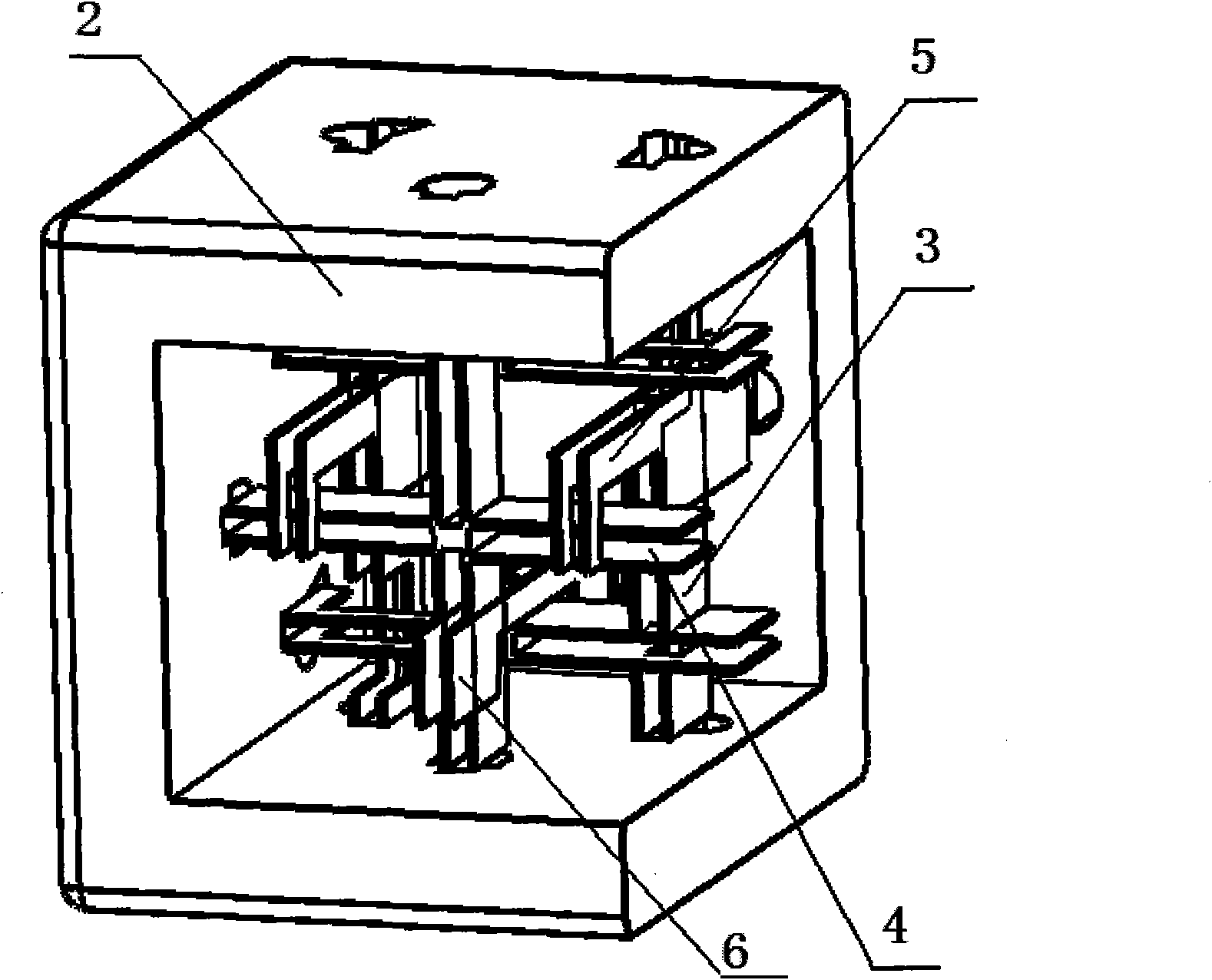

[0015] The combined cubic socket includes plug 1, socket housing 2, A-type reed 3, B-type reed 4, C-type reed 5 and D-type reed 6. The socket housing 2 is a cube structure, and the five sides are sockets. The hole has a square opening on one side, and is fixed with the plug 1 by a buckle. The A-type reed 3 is a mountain-shaped structure with a narrow mouth and a wide mouth. There are four A-type reeds 3, and the first A-type The narrow mouth of the reed 3 is in contact with the narrow mouth of the second A-shaped reed 3, the narrow mouth of the third A-shaped reed 3 is in contact with the narrow mouth of the fourth A-shaped reed 3, and the first A-shaped The wide mouth of reed 3 crosses the wide mouth of the fourth A-shaped reed 3, the second A-shaped reed 3 wide mouth crosses the third A-shaped reed 3 wide mouth, the first A-shaped reed 3 ends and the second A-type reed 3 ends are connected to the four live wire holes through buckles, and the third A-type reed 3 ends and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com