Automatic feeder

A technology of automatic feeding and moving pieces, which is applied in the direction of conveyor, transportation and packaging, etc. It can solve the problems of affecting product quality, missing tapping and mixing, and high work intensity, so as to achieve convenient tapping and transportation, safe use, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

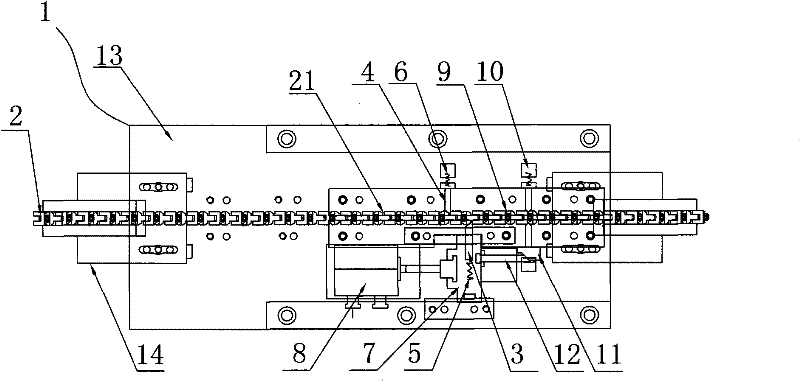

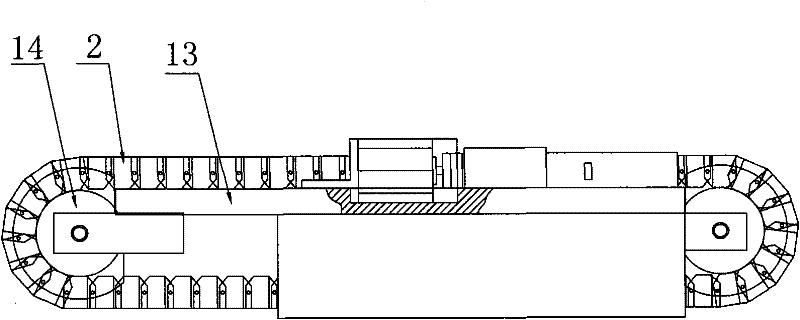

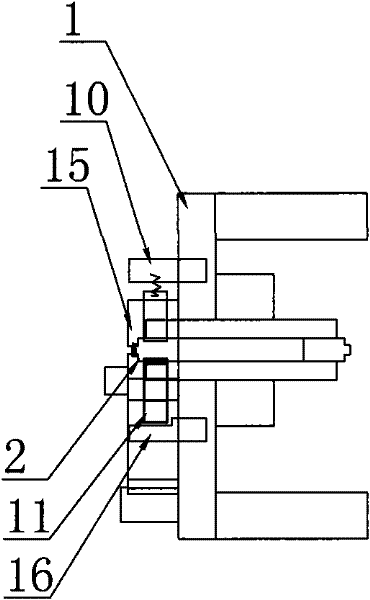

[0018] Embodiment: An automatic feeding machine, including a guide rail 1, a chain 2, a toggle piece 3 and a stop block 4. Based on the use direction, the chain 2 is slidably wound on the outer surface of the guide rail 1 in the direction of stop in the width direction and in the forward direction of the length. , the toggle piece 3 is telescopic along the width direction of the chain 2 and slidably positioned on the guide rail 1 along the length of the chain 2; On the top, the end of the toggle piece 3 and the stop block 4 close to the chain 2 are respectively accommodated in the two connection gaps 21 of the chain 2, wherein the end of the toggle piece 3 and the stop block 4 close to the chain 2 is along the forward direction of the chain 2 One side of the connection gap 21 with the chain 2 is rigidly stopped by the inner wall of this side, and the end of the toggle piece 3 and the stop block 4 is close to the chain 2 along the forward direction of the chain 2, and the other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com