Accurate measurement method for interface energy release rate of coating film-substrate structure

A technology of energy release rate and coating film, which is applied in the direction of measuring devices, instruments, and mechanical devices, and can solve problems such as measurement and calculation schemes that have not yet been seen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

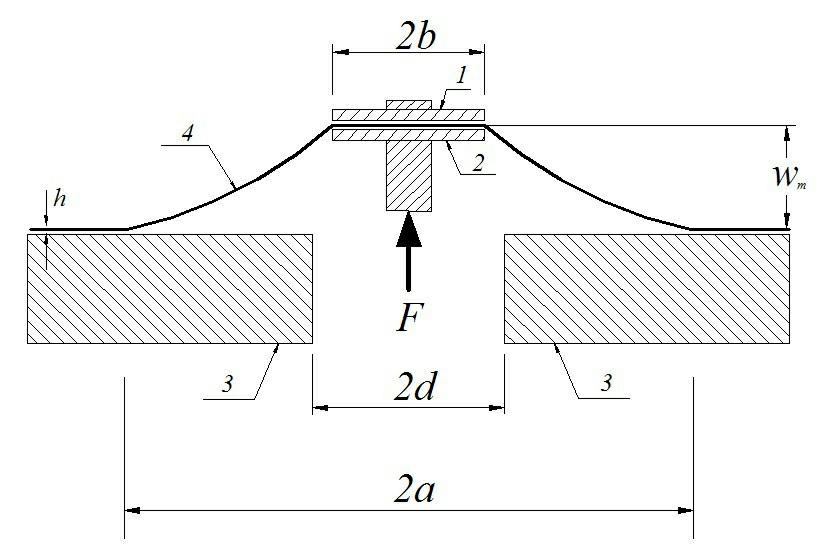

[0021] Measurement sample making

[0022] Open a radius of small hole.

[0023] Install the "Clamping Punch"

[0024] Clamp the clamping disc cap firmly with the cylindrical punch so that the film in the clamped area cannot be deformed.

[0025] Loading on film

[0026] Load the film as slowly as possible to avoid breakage of the film, and the loading speed is controlled within less than 1 mm per minute, so that the film finally forms a radius of , with a height of bubbling, and the ring area should have a certain large radius , to ensure the validity of the measurement work.

[0027] Measurement

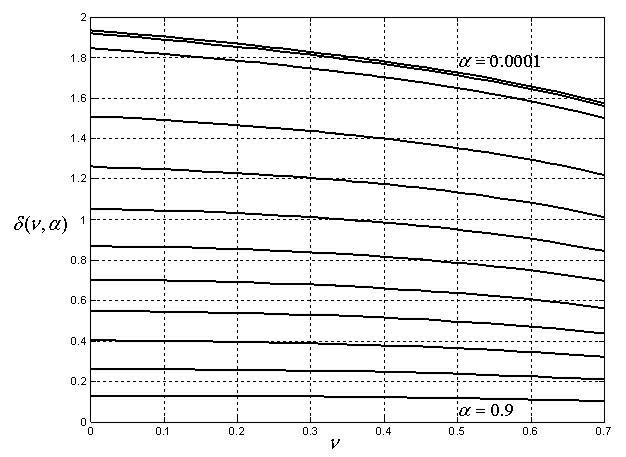

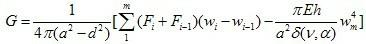

[0028] The present invention does not make specific requirements for measuring instruments, but mainly focuses on providing a method. According to the test conditions, relevant measuring instruments in this field can be used as much as possible. Try to use high-precision measuring instruments to accurately measure the thickness of the coating film , base ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com