Automatic power control circuit for controlling bias current of laser diode

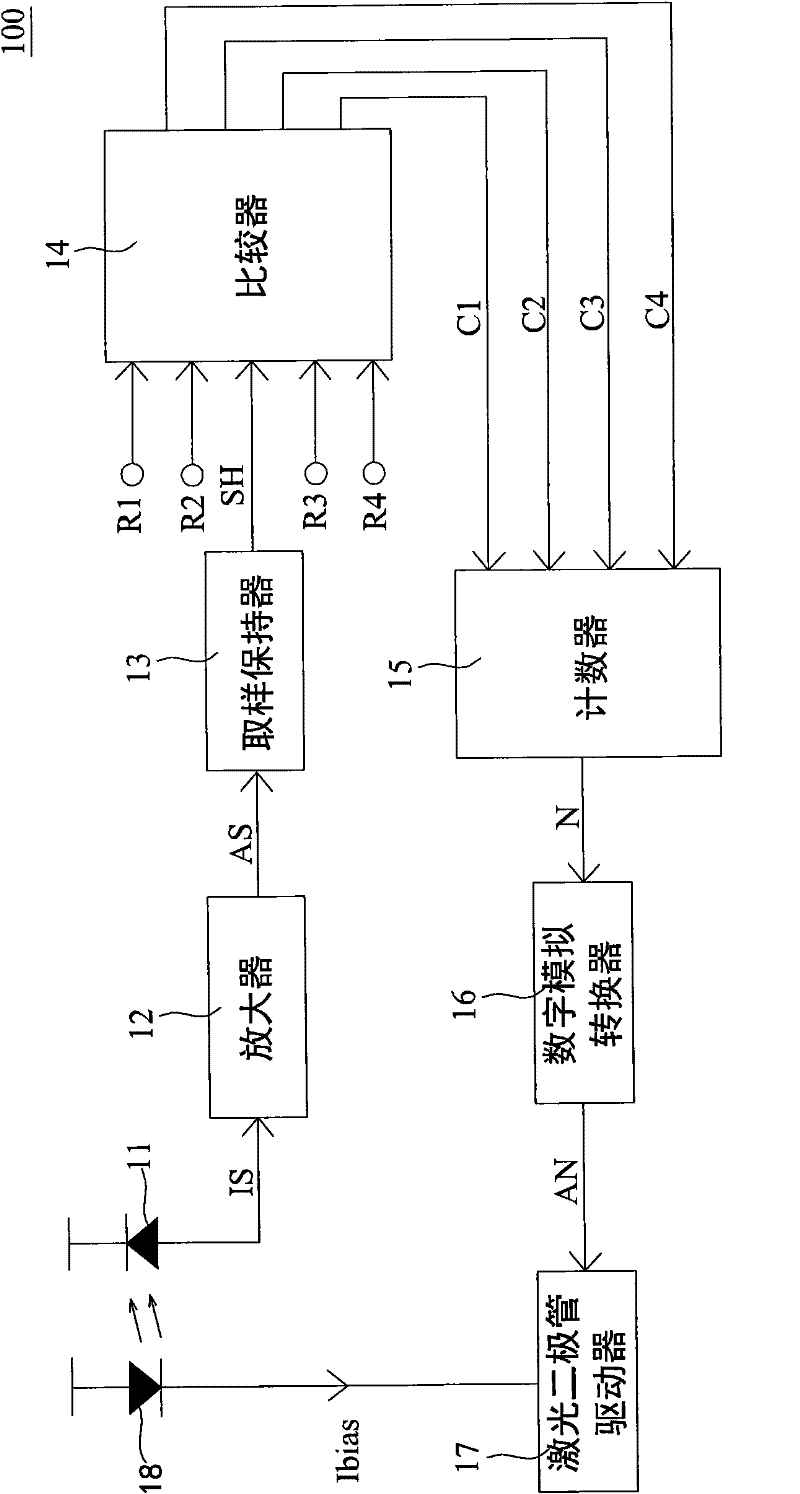

An automatic power control, laser diode technology, applied in circuits, lasers, laser parts, etc., can solve problems such as cumbersome comparison procedures, increased circuit complexity of the comparator 14, and increased circuit power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

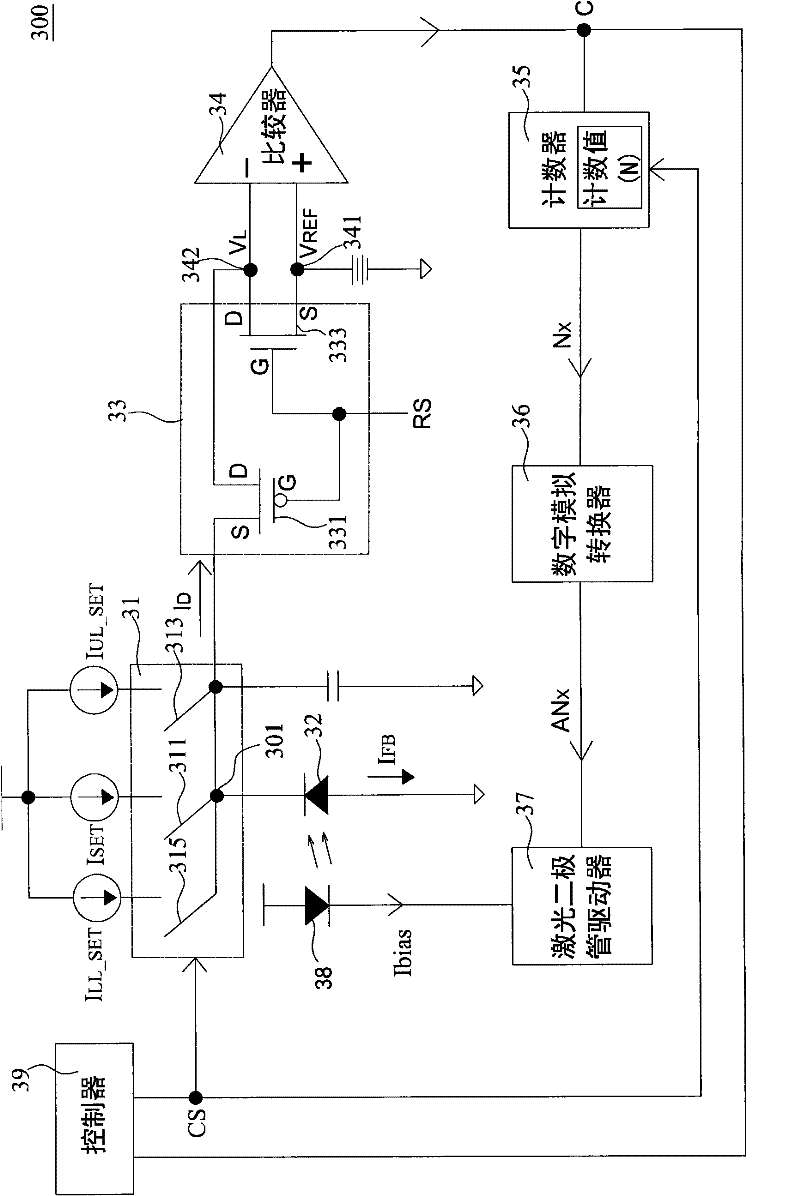

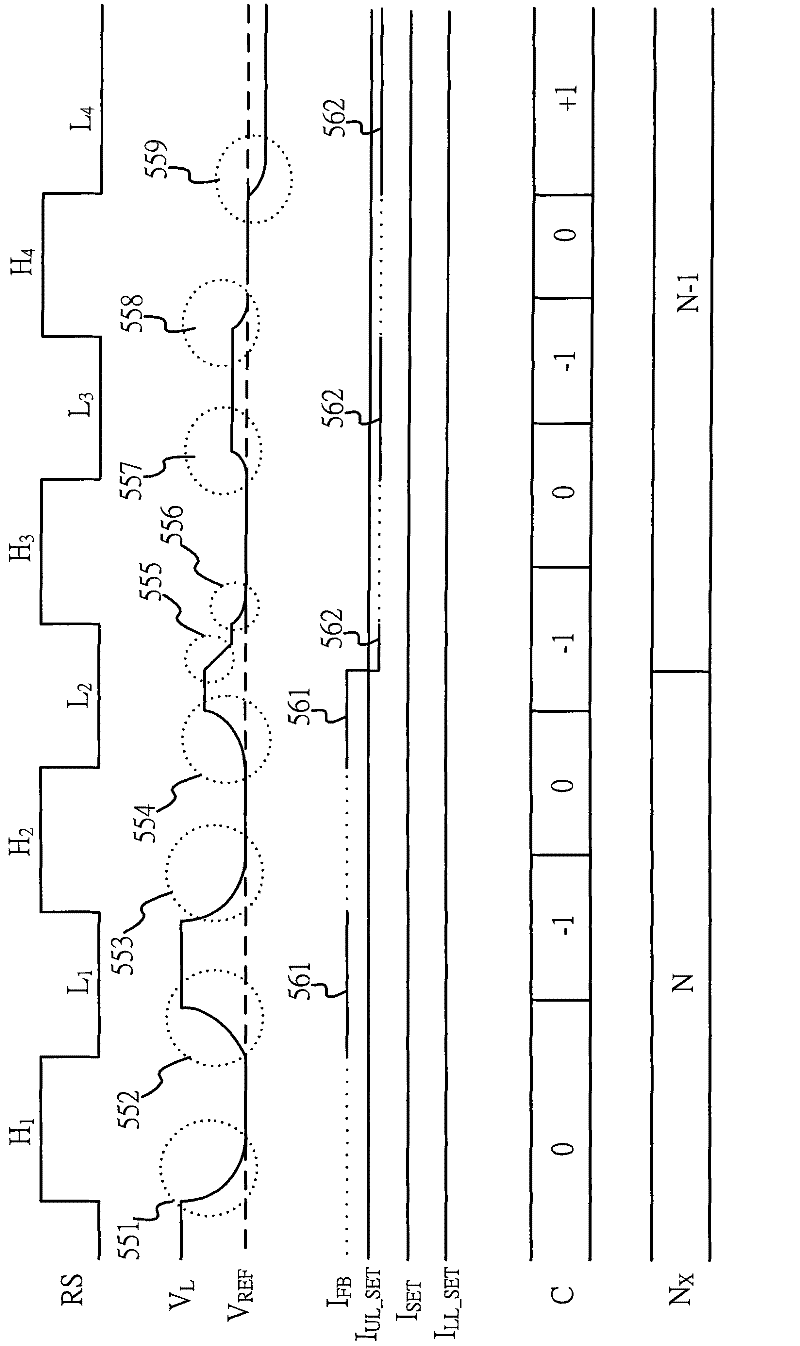

[0060] First, please refer to figure 2 , is a circuit structure diagram of a preferred embodiment of the automatic power control loop for controlling the bias current of the laser diode according to the present invention. As shown in the figure, the automatic power control circuit 300 is applied to the adjustment of the luminous intensity of the optical signal in an optical communication system, which includes a switch selector 31, a photodiode 32, a converter 33, a comparator 34, and a counter 35 . A laser diode driver 37 , a laser diode 38 and a controller 39 .

[0061] Wherein, the laser diode 38 receives a bias current (Ibias) to drive to emit light as a light source of the optical signal. The photodiode 32 senses the luminous intensity of the laser diode 38 to generate a negative feedb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com