A kind of high brightness reflective type hot-melt paint and preparation method thereof

A reflective material and reflective technology, applied in luminescent coatings, reflective/signal coatings, coatings, etc., can solve the problems of undisclosed specific types of rare earth polymer photoluminescent materials, complex construction processes, and complex components, and achieve enhanced reproducibility. Visual, ensure luminous intensity, improve the effect of luminous

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

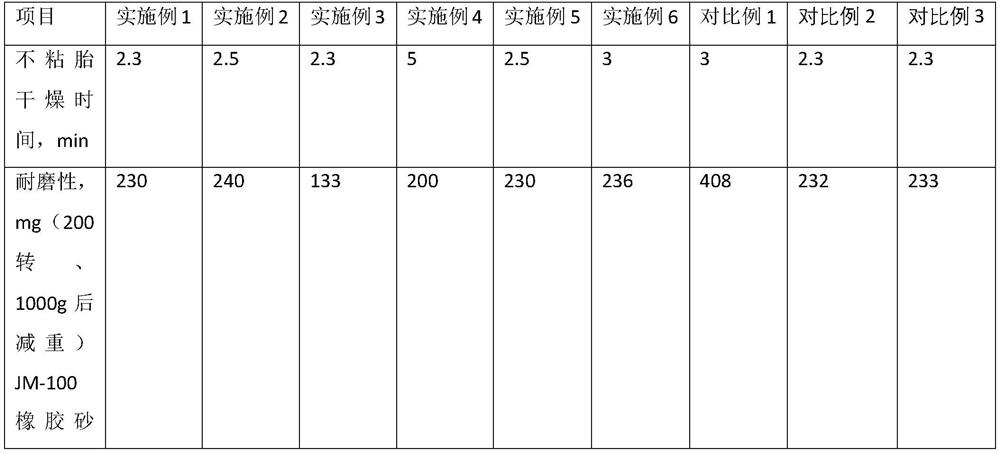

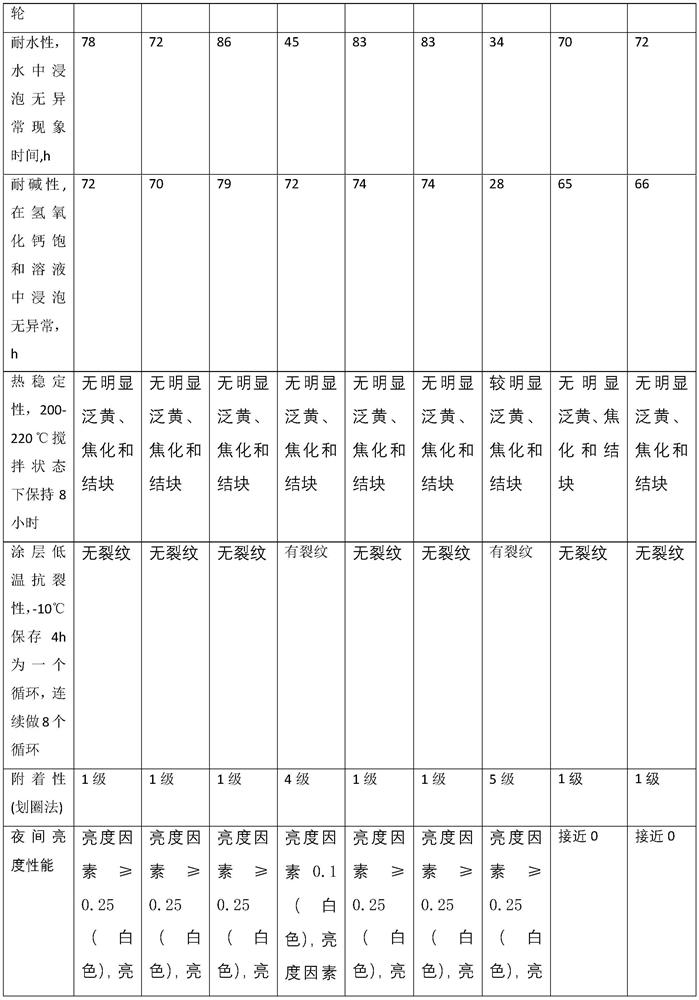

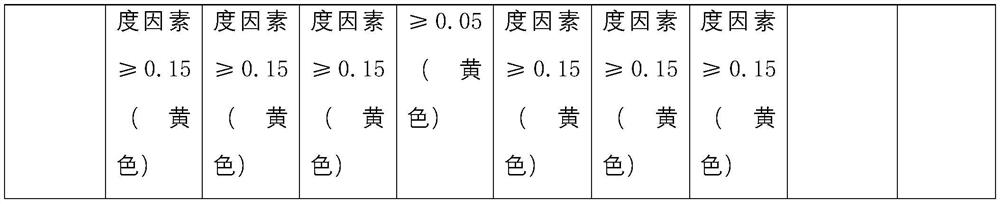

Examples

Embodiment 1

[0019] (1) Preparation of macromolecule micro / nano luminescent composite fiber: After mixing the trivalent rare earth europium ion solution with a concentration of 2mol / l with a silane coupling agent (about 1% of the molar concentration of europium ion), it is incorporated into polypropylene The polymer micro / nano light-emitting composite fiber is prepared by electrospinning in nitrile solution.

[0020] (2) Melting 10 parts by weight of EVA hot melt adhesive and 3 parts by weight of SEBS resin to form a melt-mixed resin, then 10 parts by weight of reflective glass beads, 20 parts by weight of titanium dioxide, 30 parts by weight of filler silica, 2 parts by weight of Nanometer strontium aluminate fluorescent powder and 1 part by weight of the rare earth composite polymer luminescent material prepared in step (1) are added to the molten mixed resin, and fully stirred to obtain the two-component hot-melt coating;

[0021] In the above-mentioned steps, the EVA hot melt adhesive ...

Embodiment 2

[0023] Other conditions are the same as in Example 1, except that 15 parts by weight of EVA hot melt adhesive is used.

Embodiment 3

[0025] Other conditions are the same as in Example 1, except that the VA content in the EVA resin used is 25%, and the melt flow index is 48 g / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com