A kind of ultraviolet conversion white light LED transparent ceramic material and preparation method thereof

A technology of transparent ceramics and external conversion, applied in luminescent materials, chemical instruments and methods, energy-saving lighting, etc., can solve problems such as difficulty in ensuring the uniformity of phosphor dispersion, low color rendering index of white LEDs, and lack of red light in the emission spectrum. , to achieve the effect of being beneficial to product processing and device design, excellent optical quality, and good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

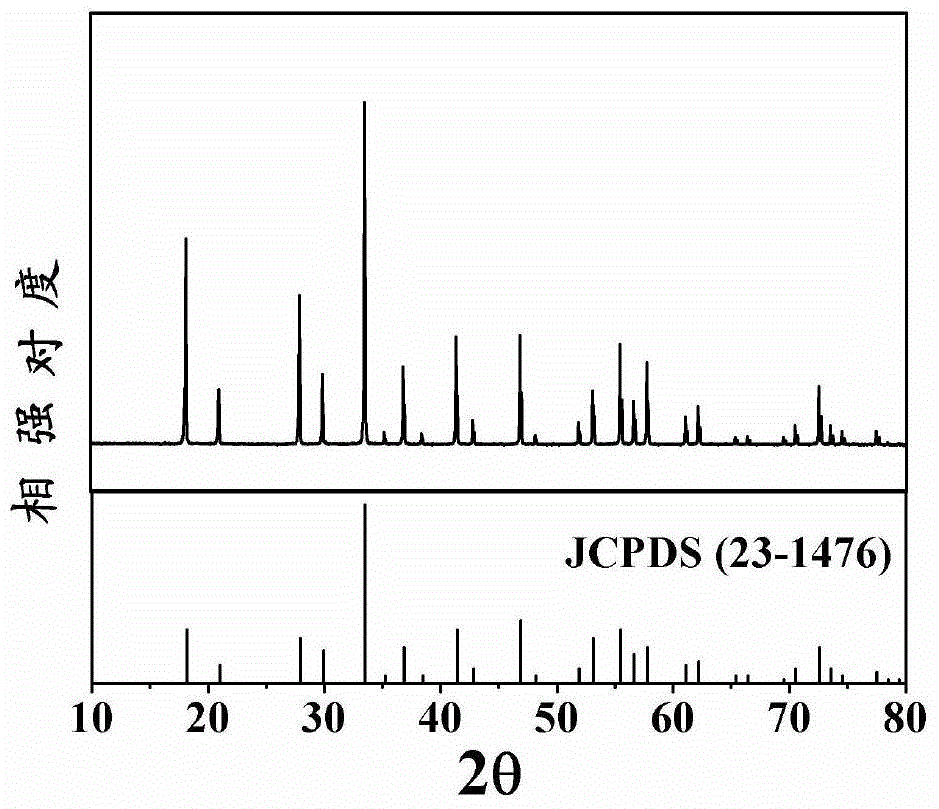

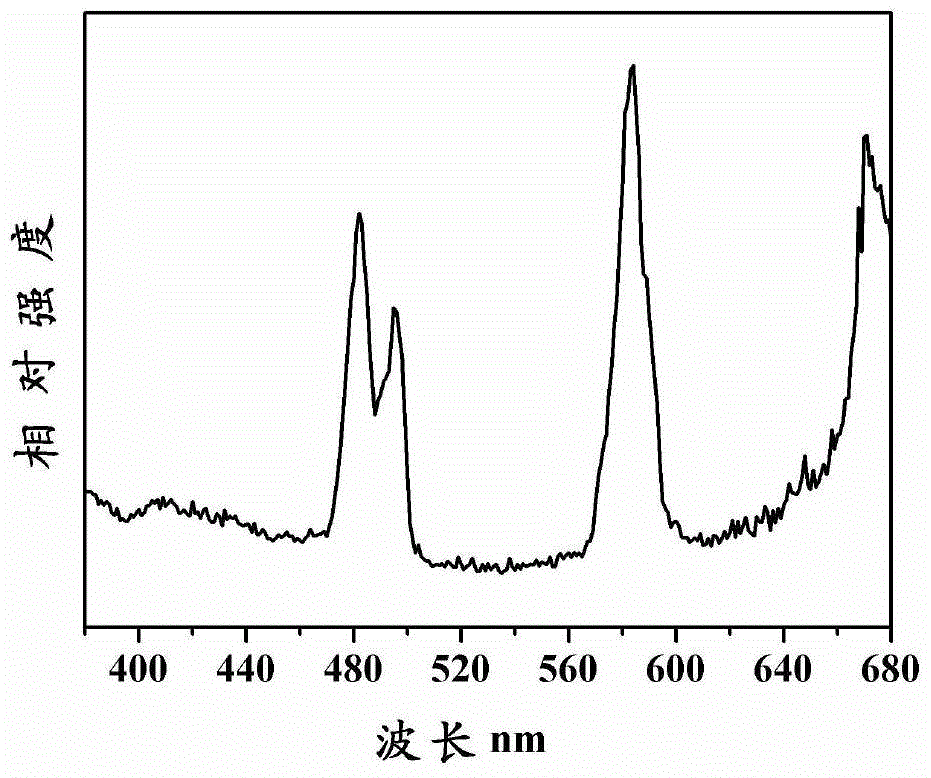

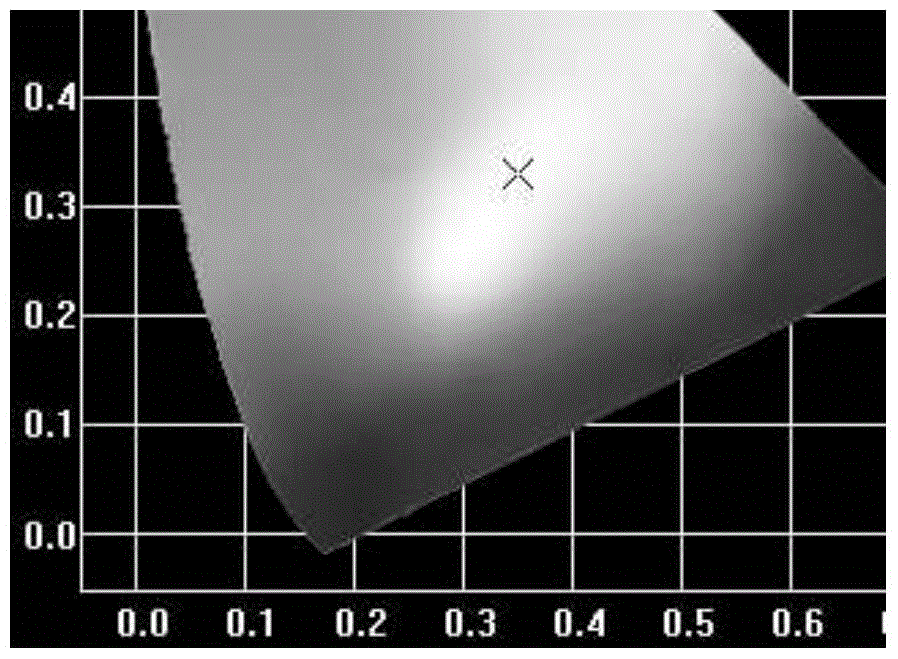

[0028] The ultraviolet to white light LED transparent ceramic material of the present invention, according to chemical formula (Yb 0.89 Dy 0.11 ) 3 Al 5 o 12 components, accurately weighed 3.0588g of α-Al with a purity of 99.99% 2 o 3 Powder, 6.3132g of Yb with a purity of 99.99% 2 o 3 Powder, 0.7385g Dy with a purity of 99.99% 2 o 3Powder, add 0.0031g of MgO powder with a purity of 99.99% and 0.0705g of high-purity TEOS reagent as composite sintering aids, and use a planetary mill to fully mix after blending. 20ml of absolute ethanol was used as the ball milling medium, the rotational speed of the planetary mill was 200r / min, and the ball milling time was 12 hours. After drying in a constant temperature oven at 60°C for 24 hours, it was ground and passed through a 200-mesh sieve. The powder is subjected to axial pre-compression molding under a pressure of 15MPa, and then subjected to cold isostatic pressing at a pressure of 200MPa to obtain a dense green body. The ...

Embodiment 2

[0030] The near-ultraviolet-to-white LED transparent ceramic material of the present invention, according to the chemical formula (Yb 0.995 Dy 0.005 ) 3 Al 5 o 12 components, accurately weighed 3.0588g of α-Al with a purity of 99.99% 2 o 3 Powder, 7.0580g of Yb with a purity of 99.99% 2 o 3 Powder, 0.0336g of Dy with a purity of 99.99% 2 o 3 For the powder, add 0.0031g of MgO powder with a purity of 99.99% and 0.0608g of high-purity TEOS reagent as composite sintering aids, and use a planetary mill to fully mix after blending. 15ml of absolute ethanol was used as the ball milling medium, the rotational speed of the planetary mill was 180r / min, and the ball milling time was 12 hours. After drying in a constant temperature oven at 60°C for 24 hours, it was ground and passed through a 200-mesh sieve. The powder is subjected to axial pre-compression molding under a pressure of 18MPa, and then subjected to cold isostatic pressing at a pressure of 200MPa to obtain a dense ...

Embodiment 3

[0032] The near-ultraviolet-to-white LED transparent ceramic material of the present invention, according to the chemical formula (Yb 0.85 Dy 0.15 ) 3 Al 5 o 12 components, accurately weighed 3.0588g of α-Al with a purity of 99.99% 2 o 3 Powder, 6.0294g of Yb with a purity of 99.99% 2 o 3 Powder, 1.0071g Dy with a purity of 99.99% 2 o 3 Powder, add 0.0051g of MgO powder with a purity of 99.99% and 0.0507g of high-purity TEOS reagent as composite sintering aids, and use a planetary mill to fully mix after blending. 20ml of absolute ethanol was used as the ball milling medium, the rotational speed of the planetary mill was 220r / min, and the ball milling time was 15 hours. After drying in a constant temperature oven at 60°C for 24 hours, it was ground and passed through a 200-mesh sieve. The powder is subjected to axial pre-compression molding under a pressure of 12MPa, and then subjected to cold isostatic pressing at a pressure of 250MPa to obtain a dense green body. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com