Device for heating and filling tooth in dental canal

A technology of internal heating and root canal, which is applied in the direction of filling teeth, dentistry, and adding protective layers. It can solve the problems of gutta-percha filling side branch root canals not in place, gutta-percha carbonization, failure, etc., to avoid scalding surrounding tissues, temperature Easy to control and reduce the effect of bacterial infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

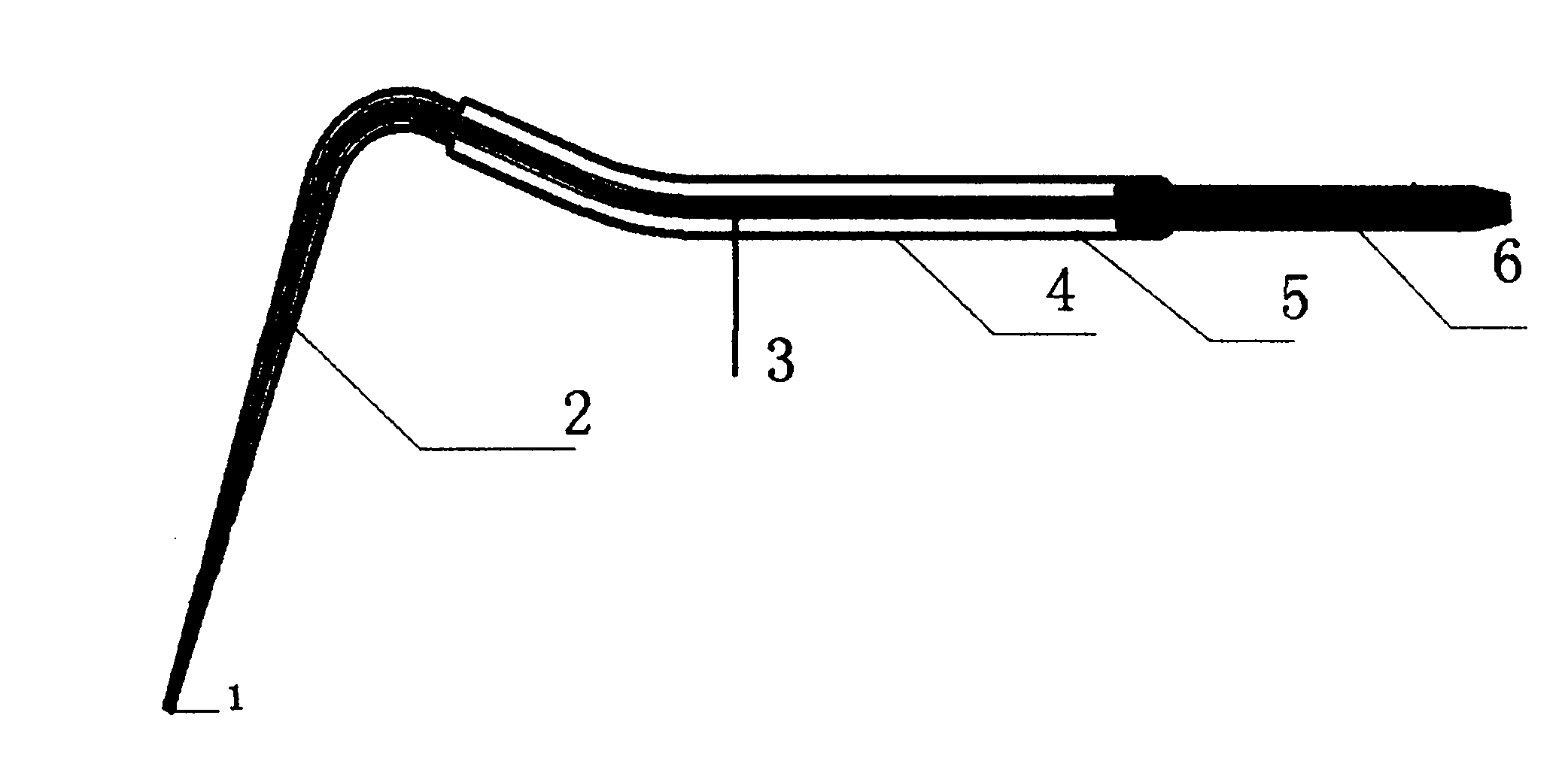

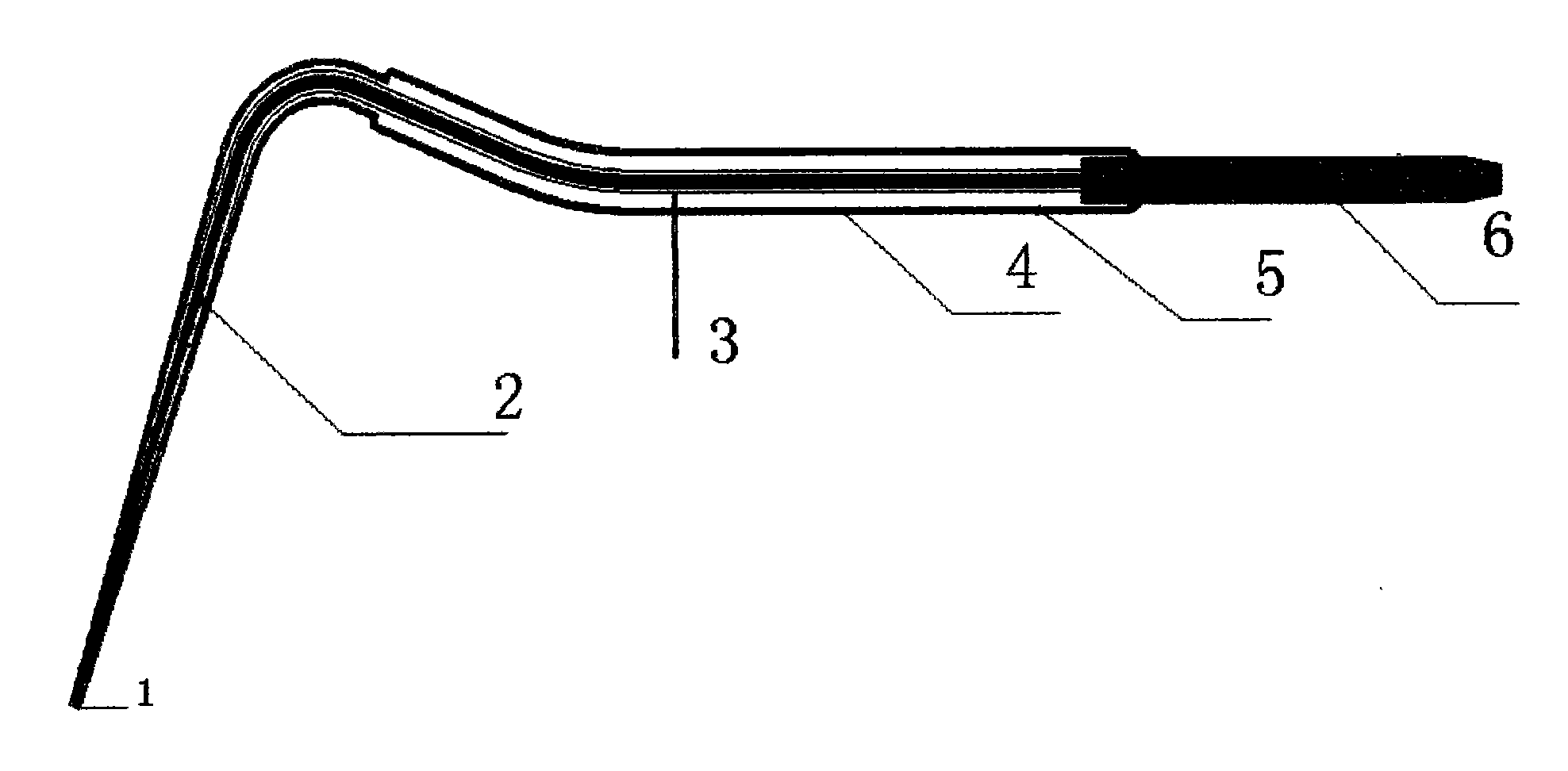

[0014] refer to figure 1 Below by embodiment the present invention is described in detail:

[0015] A device for heating and filling teeth in a root canal, comprising a heating tip 1, a low-resistance inner conductor 2, a high-temperature-resistant insulating sleeve 3, a low-resistance outer conductor 4, a negative electrode 5, and a positive electrode 6. The heating tip 1 is made of a high-temperature-resistant heating material The diameter of the heating tip: 0.5mm, the heating tip 1 and the positive electrode 6 form a "7" shape, the back of the heating tip 1 is connected to the low-resistance inner conductor 2 and the low-resistance outer conductor 4, and the low-resistance inner conductor 2 and the low-resistance outer conductor There is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com