Mold capable of measuring internal temperature of castings directly in extrusion casting process

A squeeze casting, internal temperature technology, applied in the direction of thermometers, thermometers, measuring devices, etc., which use electrical/magnetic components directly sensitive to heat, can solve problems such as unfavorable temperature measurement, difficulty in demoulding castings, and easy damage to molds, etc. Achieve the effect of continuous multi-mode temperature measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The structural principle and working principle of the present invention will be described in detail below.

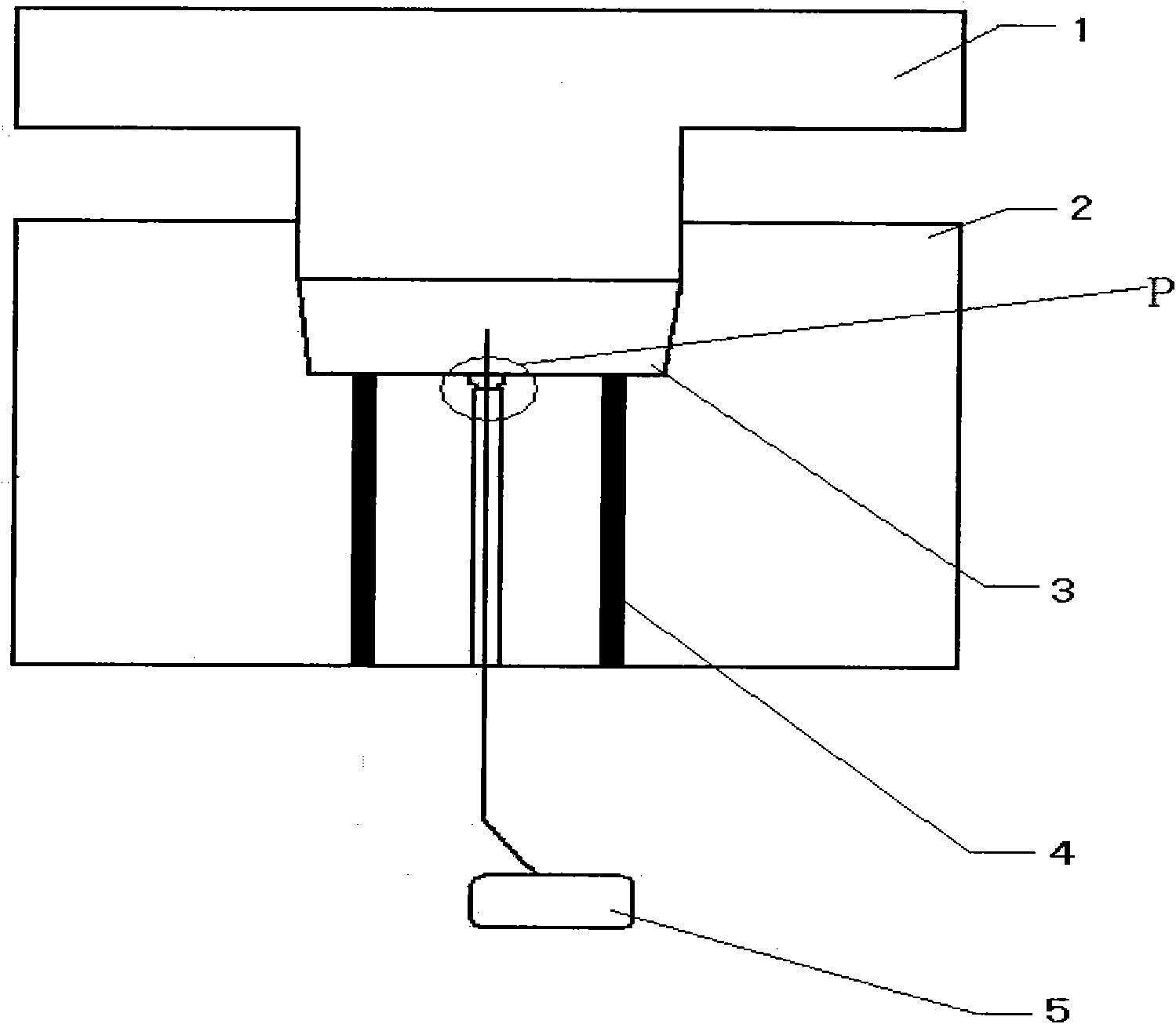

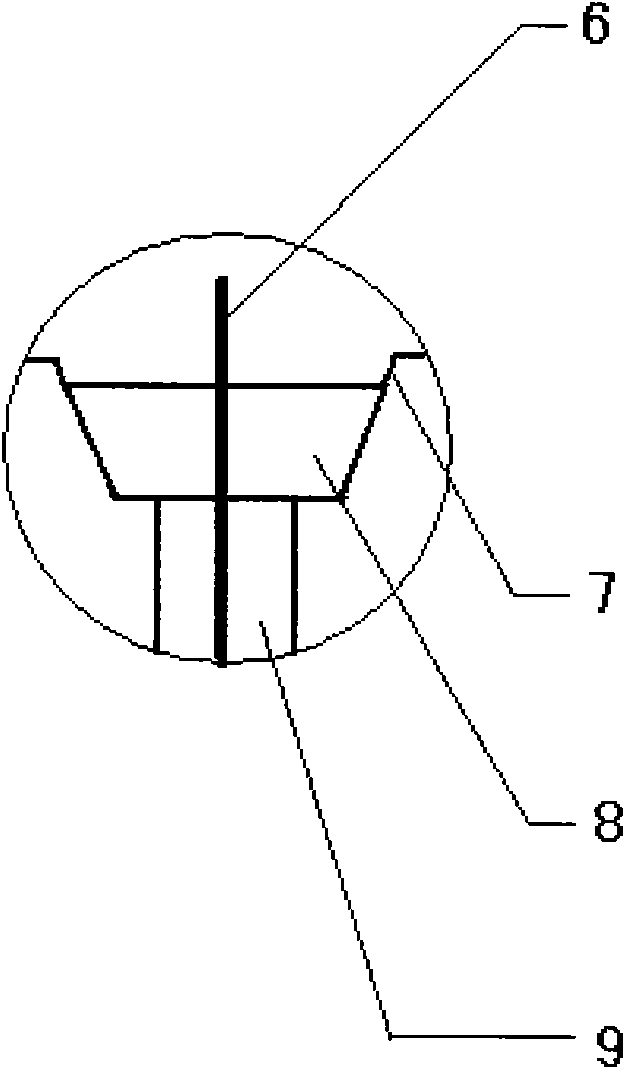

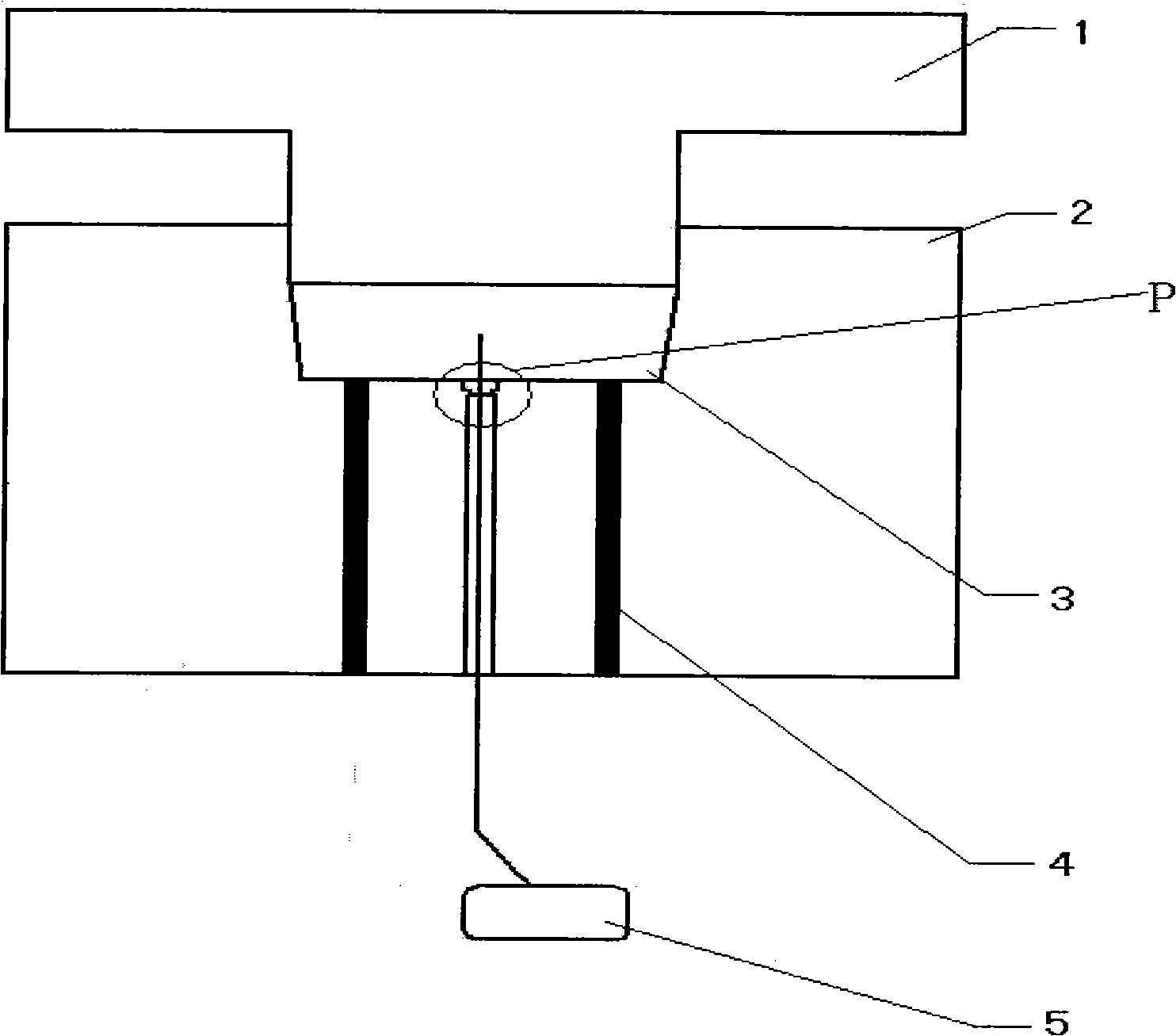

[0014] Referring to the accompanying drawings, a mold for directly measuring the internal temperature of a casting in the extrusion casting process includes a T-shaped upper mold 1 and a concave lower mold 2 matching it, and a movable ejector pin 4 is arranged in the lower mold 2 The casting 3 is poured in the concave area of the lower mold 2, and at least one groove 7 is arranged in the concave area of the lower mold 2. The number of the grooves 7 is set according to actual needs, and the temperature at several places of the casting 3 needs to be measured. Each groove 7 is provided with a thermocouple fastening boss 8, and the thermocouple 6 passes through the thermocouple fastening boss 8 and forms a tight fit with it. The vertical direction of the lower mold 2 is provided with a through hole 9, and the thermocouple 6 The lead end is connected to the data r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com