Anti-fake bottle cap opened after being ejected

An anti-counterfeiting bottle cap and open-type technology, which is applied in the directions of closure, packaging, transportation and packaging, etc., can solve the problems of difficulty in thread design and assembly of the outer body and the inner ejection part, difficulty in ensuring anti-counterfeiting effect, lack of capping in the ejection structure, etc. , to achieve the effect of many styles of liquid outlets, small unscrewing force and high ejection height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

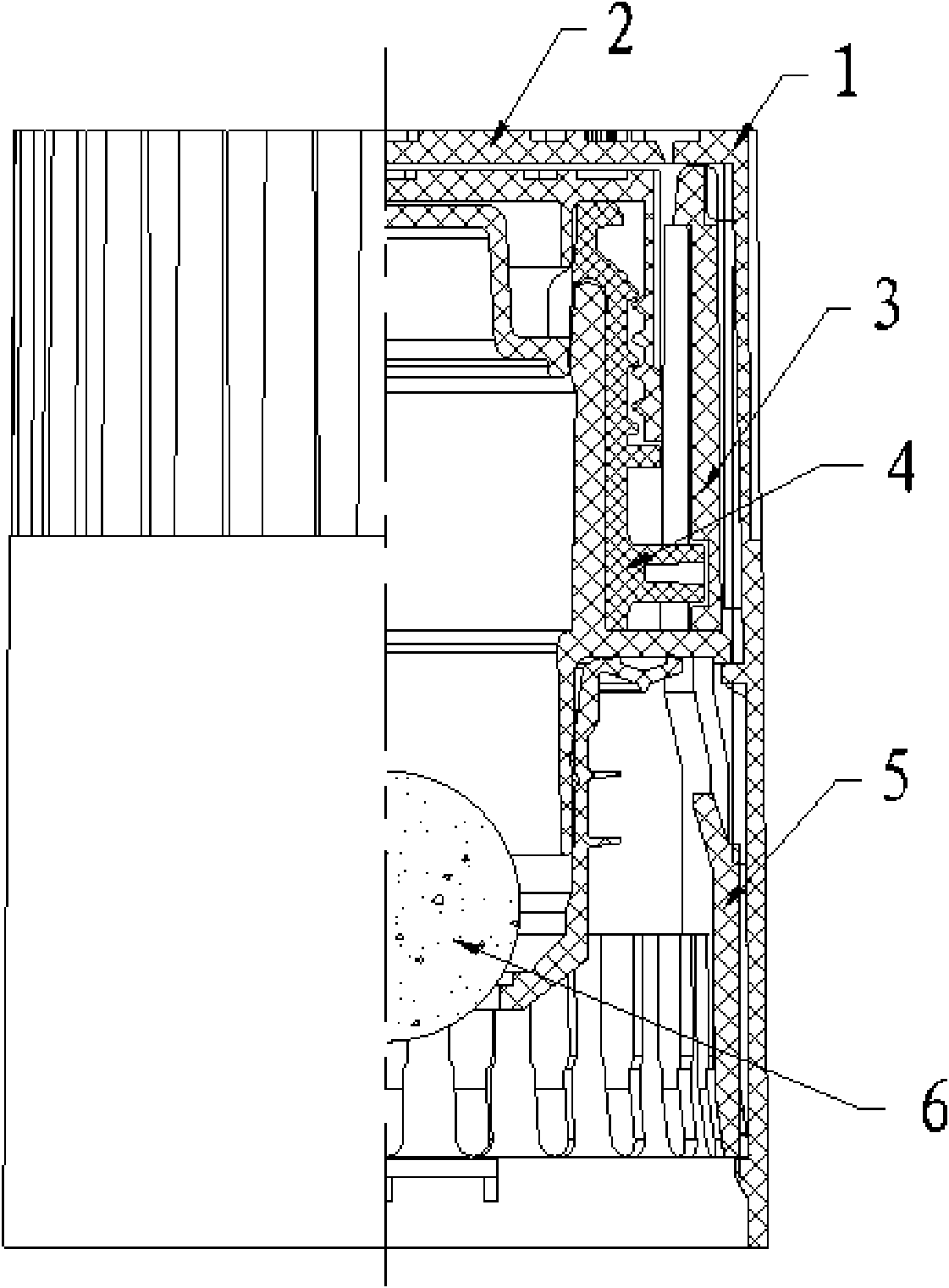

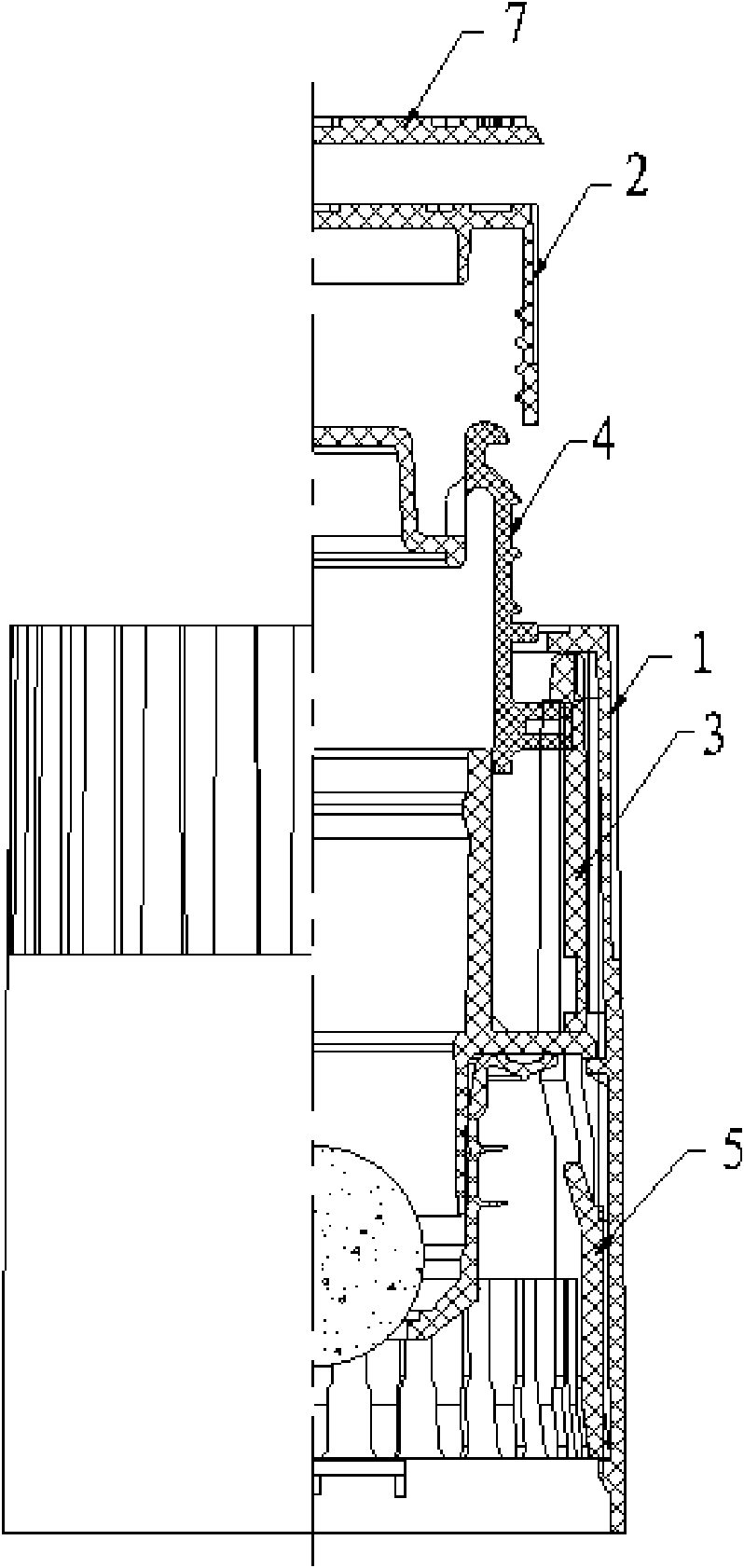

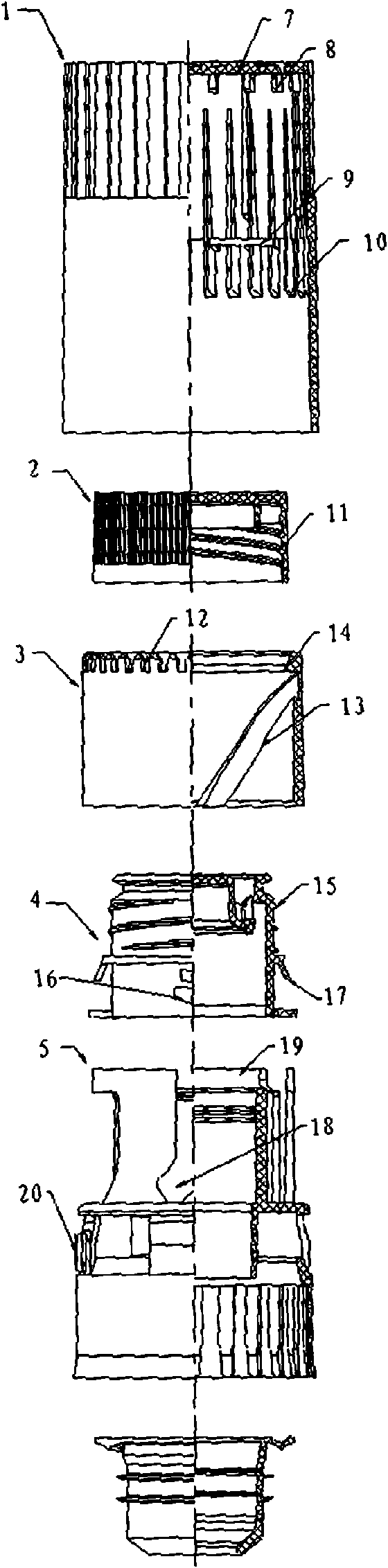

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the ejection and re-opening type anti-counterfeiting bottle cap described in this embodiment includes an outer sleeve 1 and an inner sleeve 5, the inner sleeve 5 is positioned in the outer sleeve 1 with a top, and the outer sleeve 1 is provided with an axial positioning buckle 9 , the axial positioning buckle 9 buckles the protrusion on the inner sleeve 5, so that the outer sleeve 1 cannot move up and down, and a lead sleeve 3 for rotation transmission with the outer sleeve 1 is provided between the inner sleeve 5 and the outer sleeve 1, and the guide sleeve 3 is provided with Spiral groove 13, an ejector 4 is arranged in the inner sleeve 5, the top of the ejector 4 is provided with an ejector 7 connected to the ejector 4, the side wall of the ejector 4 is provided with a toggle head 16, and the ejector The upper end of the outlet piece 4 is provided with a cover 2, the toggle head 16 passes through a vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com