Method for repairing broken rubber conveying belt

A technology for conveyor belt damage, which is applied in the field of repairing rubber conveyor belt damage, can solve the problems of poor comprehensive performance and limited application, and achieve the effects of low heating temperature, large temperature control range and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

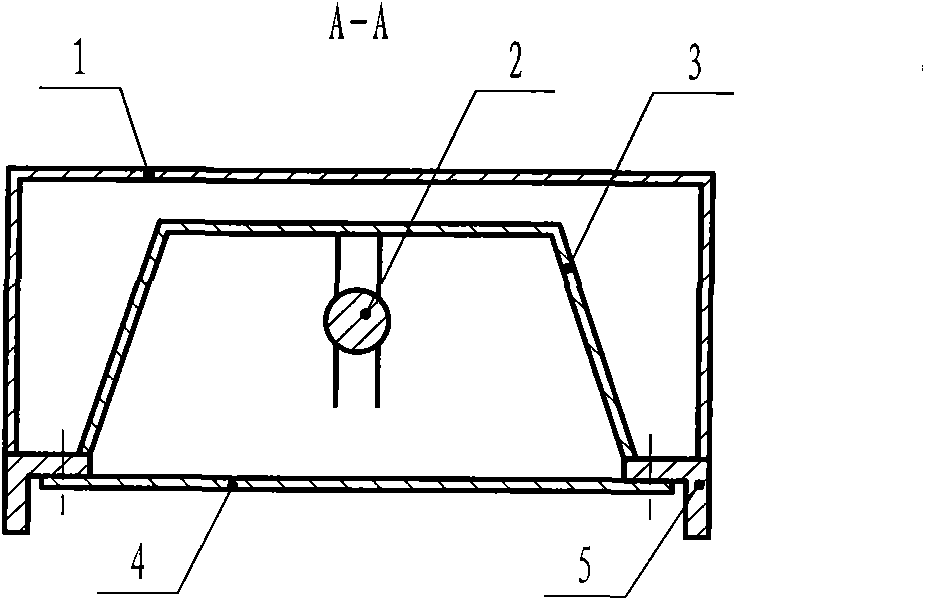

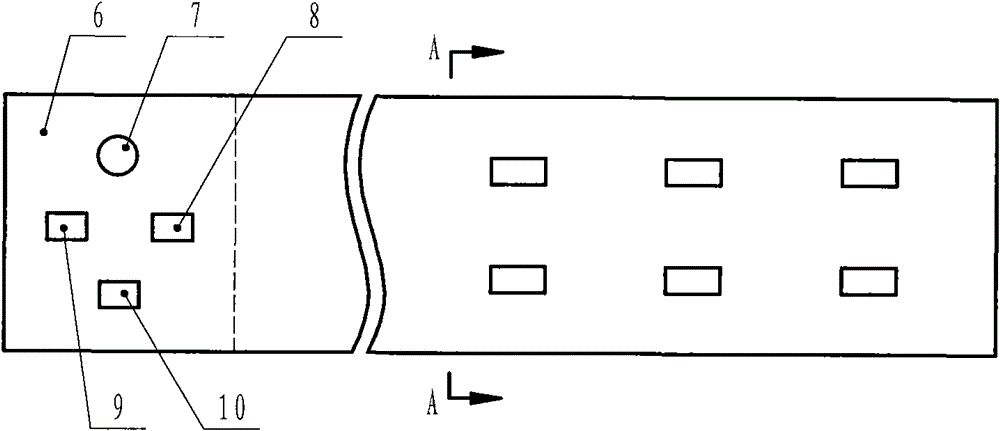

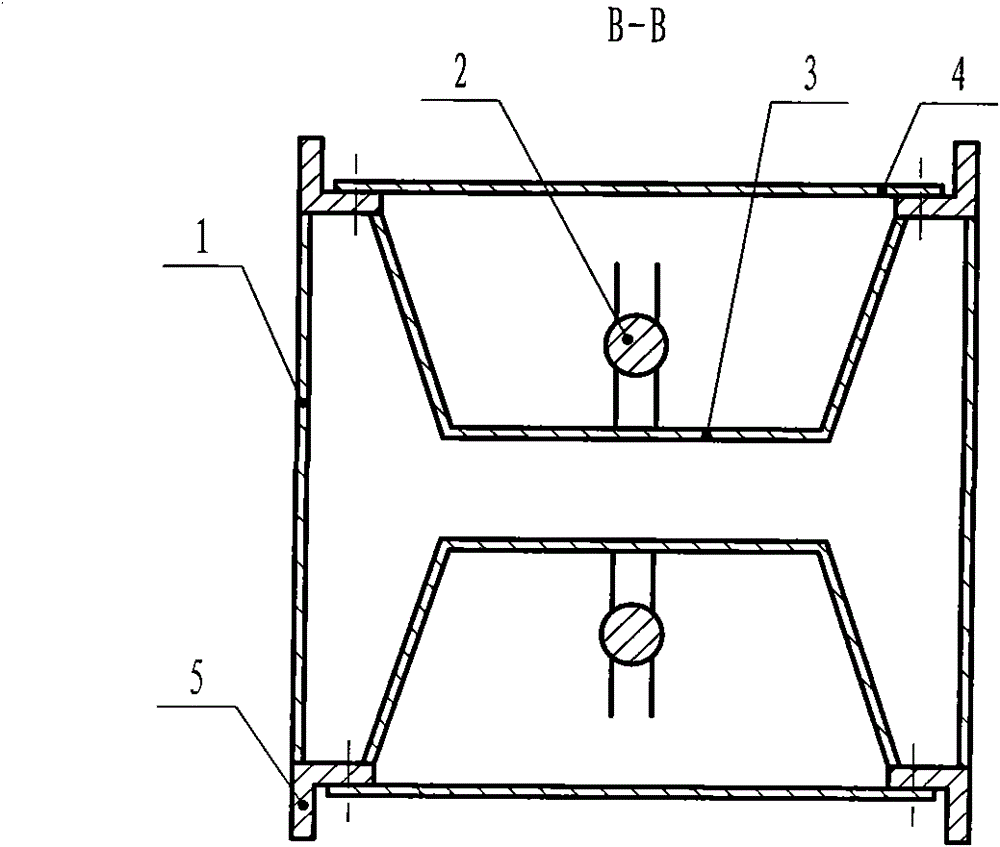

Image

Examples

Embodiment Construction

[0031] A method for repairing damaged rubber conveyor belts is carried out in accordance with the following steps:

[0032] a. Grinding: Firstly, use an angle grinder to polish and roughen the area within 5-20 cm around the damaged part of the conveyor belt, and then polish and roughen the bonding surface of the repair strip with an angle grinder;

[0033] b. Chemical treatment of the surface of the conveyor belt: use rubber treatment agent for treatment, apply the rubber treatment agent evenly on the surface of the polished conveyor belt, and dry it;

[0034] c. Glue brushing: Apply the adhesive evenly on the treated surface of the conveyor belt and the repair strip;

[0035] d. Heating to activate adhesiveness: Heat the conveyor belt and repair strip to 50°C-120°C with a heating device and keep it for 2-5 minutes;

[0036] e. Bonding: In a hot state, that is, when the temperature is above 50°C, quickly attach the adhesive surface of the repair strip to the surface of the da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com