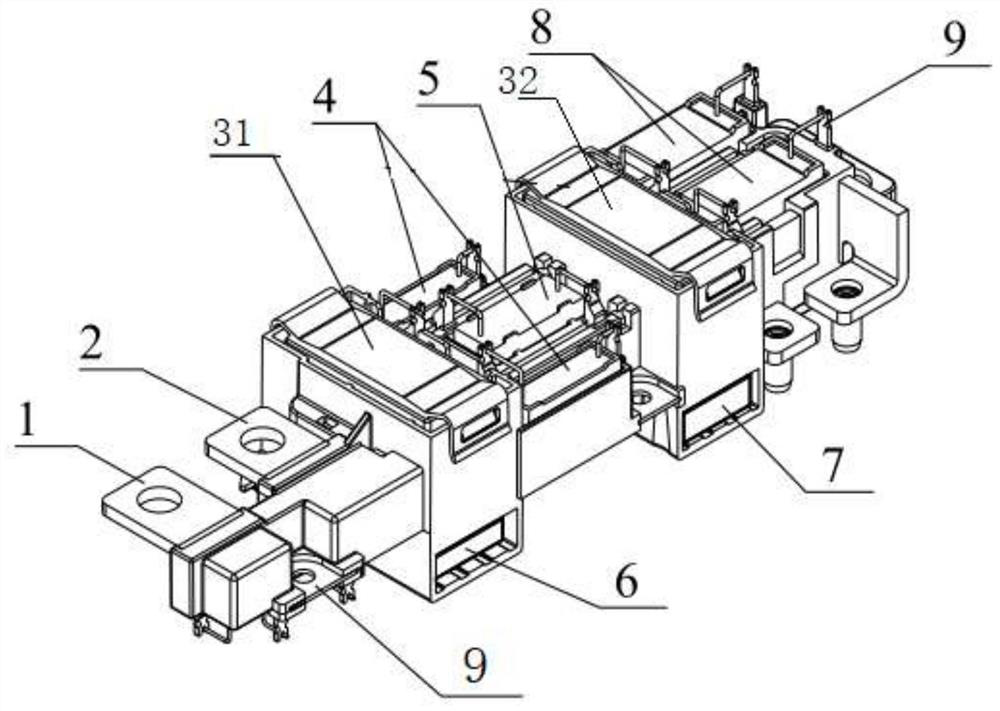

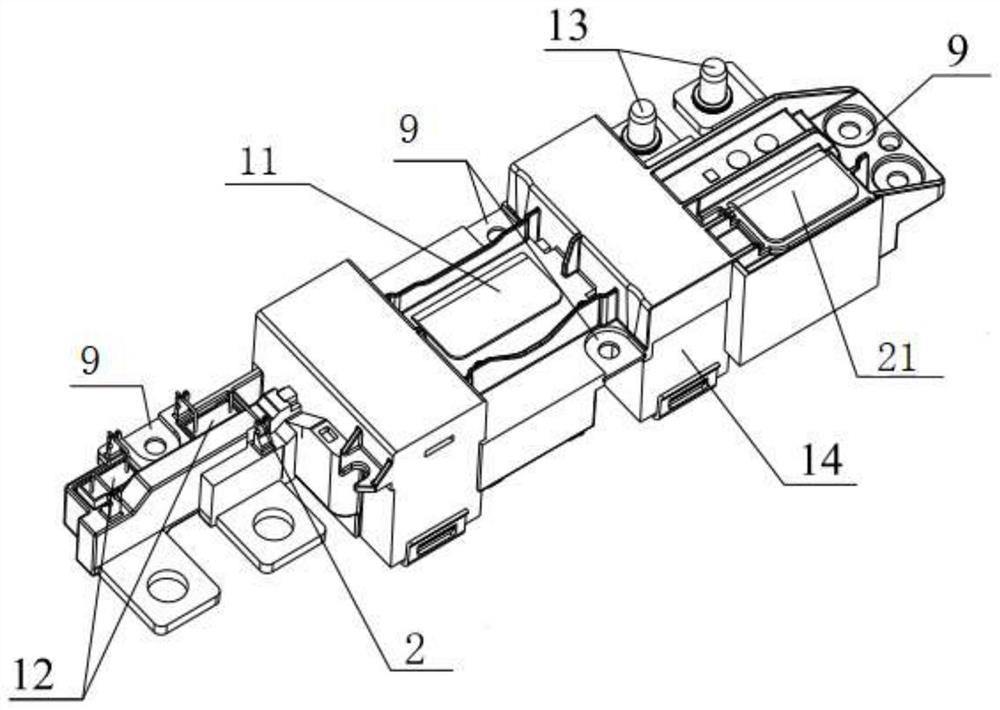

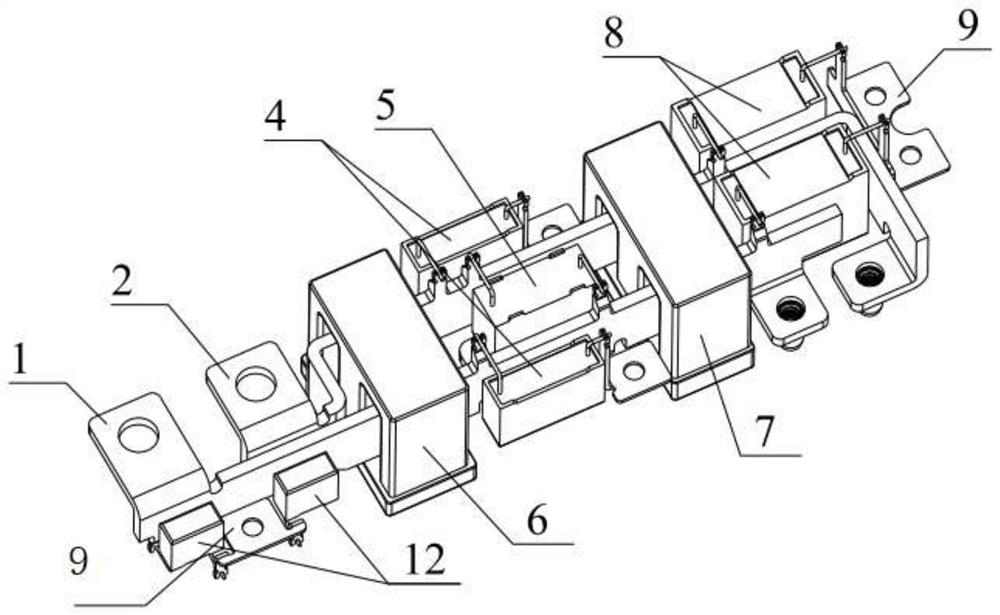

Multistage EMI filter for motor controller

A motor controller and filter technology, applied in the modification of electrical components, power electronics, cooling/ventilation/heating transformation, etc., can solve the problems of large fixed equipment investment, large one-time investment in molds, and production costs, etc. Achieve the effect of reducing process complexity and equipment investment, avoiding the use of potting materials, and improving manufacturability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following description serves to disclose the invention to enable those skilled in the art to practice the invention. The preferred embodiments described below are given by way of example only, and other obvious modifications will occur to those skilled in the art. The basic principles of the invention defined in the following description may be applied to other embodiments, variations, improvements, equivalents, and other technical solutions without departing from the spirit and scope of the invention.

[0032] The invention discloses a multi-stage EMI filter for a motor controller. The specific embodiments of the invention will be further described below with reference to the preferred embodiments.

[0033] In the embodiments of the present invention, those skilled in the art should note that the negative electrode copper bar, the positive electrode copper bar, and the grounding copper bar involved in the present invention may be regarded as the prior art.

[0034...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com