Connection structure of electromagnetic cooker surface

A connection structure and cooktop technology, applied in the direction of furnace/stove top, etc., can solve problems such as appearance defects, difficult production process, long production cycle, etc., and achieve the effects of facilitating production management, eliminating the need for curing time, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

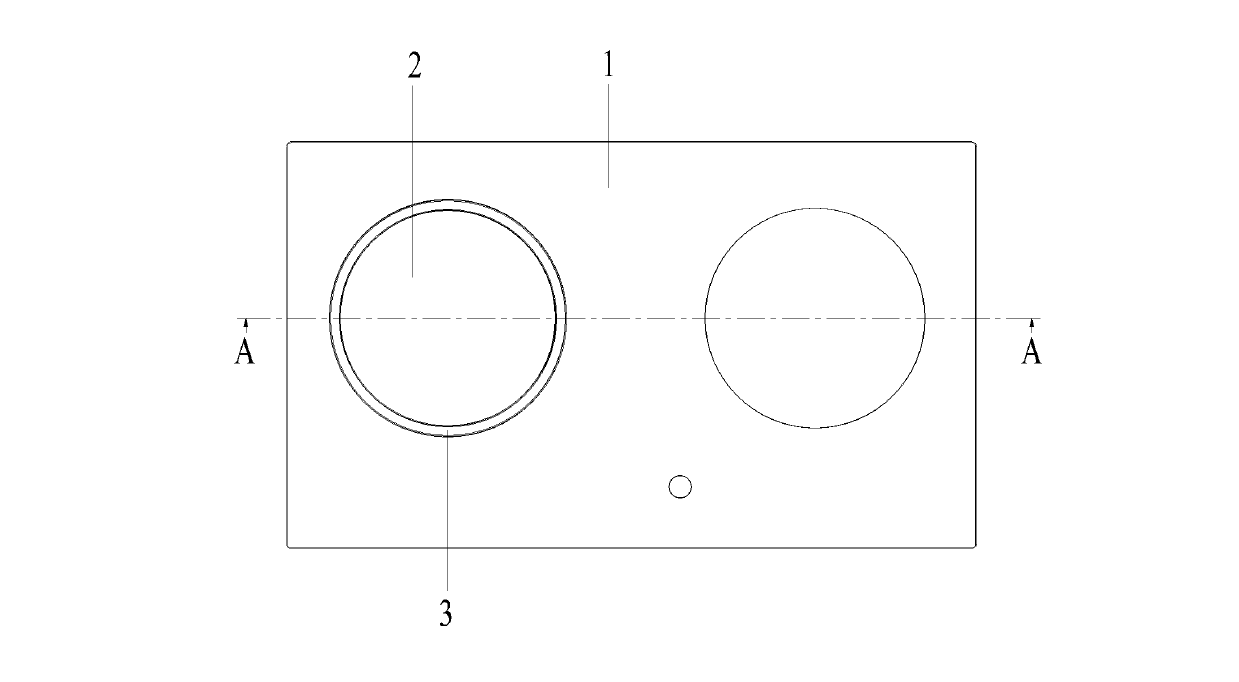

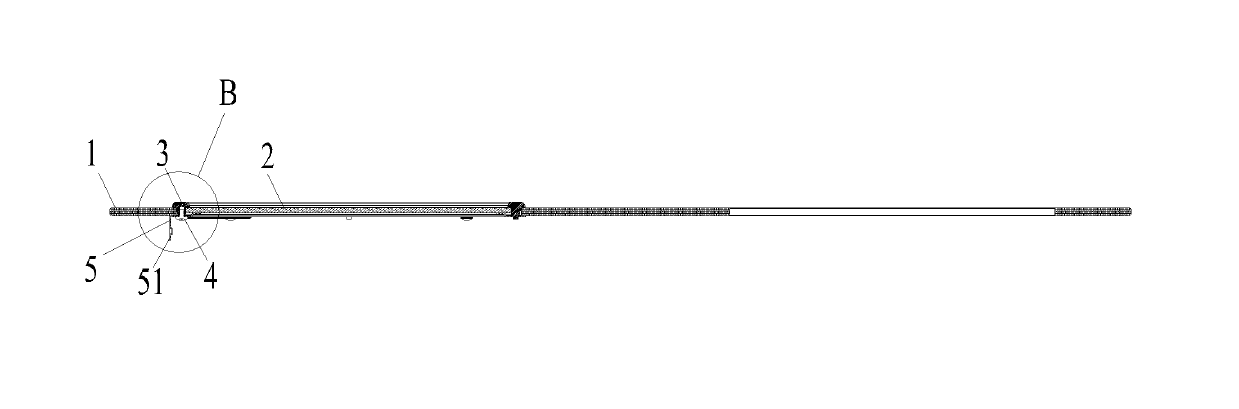

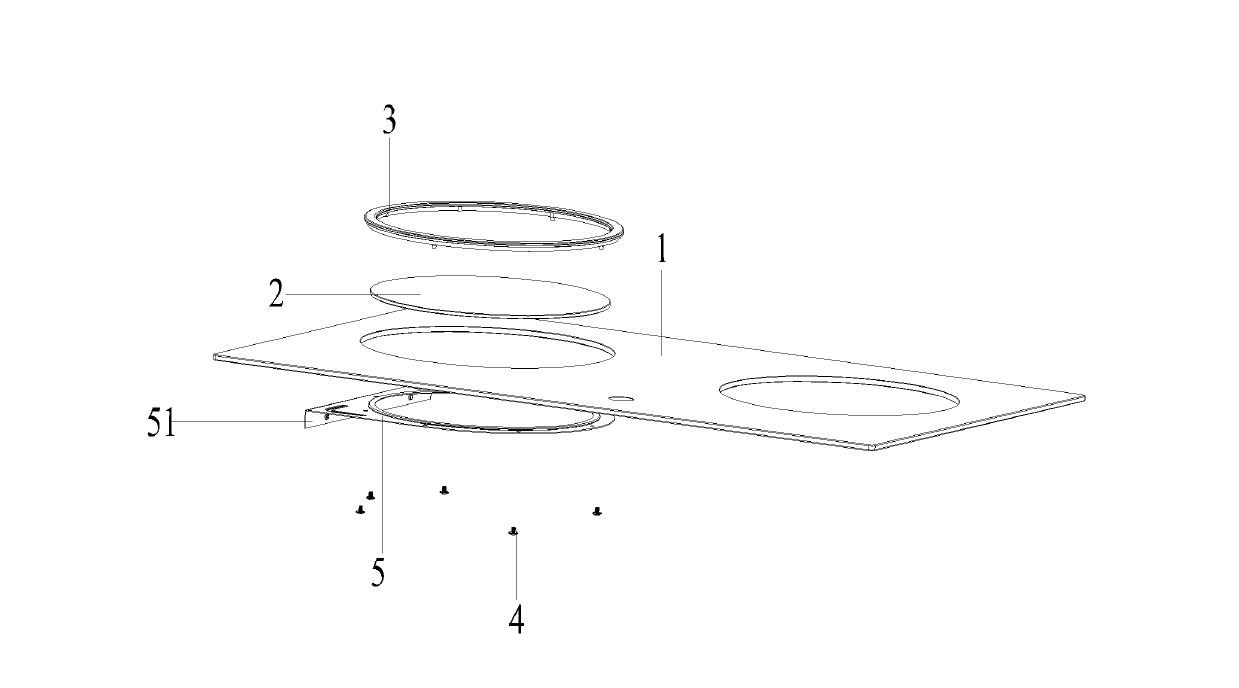

[0025] See Figure 1-Figure 6 , figure 1 It is a top view structural diagram of the connection structure of the electromagnetic cooktop in the embodiment of the present invention; figure 2 for figure 1 Schematic diagram of the cross-sectional structure of the A-A direction of the connection structure of the medium induction cooktop; image 3 It is a schematic diagram of the decomposition structure of the connection structure of the electromagnetic cooktop in the embodiment of the present invention; Figure 4 for figure 2 Enlarged image at B. Figure 5 It is a structural schematic diagram of the decorative ring in the connection structure of the electromagnetic cooktop according to the embodiment of the present invention. Image 6 It is a schematic diagram of the rear structure of the decorative ring in the connection structure of the electromagnetic cooktop according to the embodiment of the present invention.

[0026] The connection structure of the electromagnetic co...

Embodiment 2

[0037] The difference between this embodiment and Embodiment 1 is that the connection structure of the induction cooker surface also includes a sealing gasket, which is arranged on the part where the support contacts the heating plate, the cooker panel and the decorative ring, so as to prevent water from entering the induction cooker. Inside, it's even safer. The heating plate is made of glass-ceramic.

[0038] The upper surface of the decorative ring is provided with a ring-shaped protrusion higher than the heating plate. The ring-shaped protrusion is 8mm higher than the heating plate, which is conducive to placing the pot on the heating plate more accurately, and can also prevent the pot from deviating from the heating position.

[0039] The assembly process of the connection structure of the electromagnetic cooktop provided in this embodiment is as follows:

[0040] Put the heating plate into the decorative ring, and then put the two into the stove panel as a whole, fix th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com