Segmental beam end formwork

An end formwork and segment beam technology, which is applied in the directions of mold fixtures, mold auxiliary parts, ceramic molding machines, etc., can solve the problem that the formwork body and shear keys are prone to loosening, segment beam products are unqualified, and segment beam types single problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

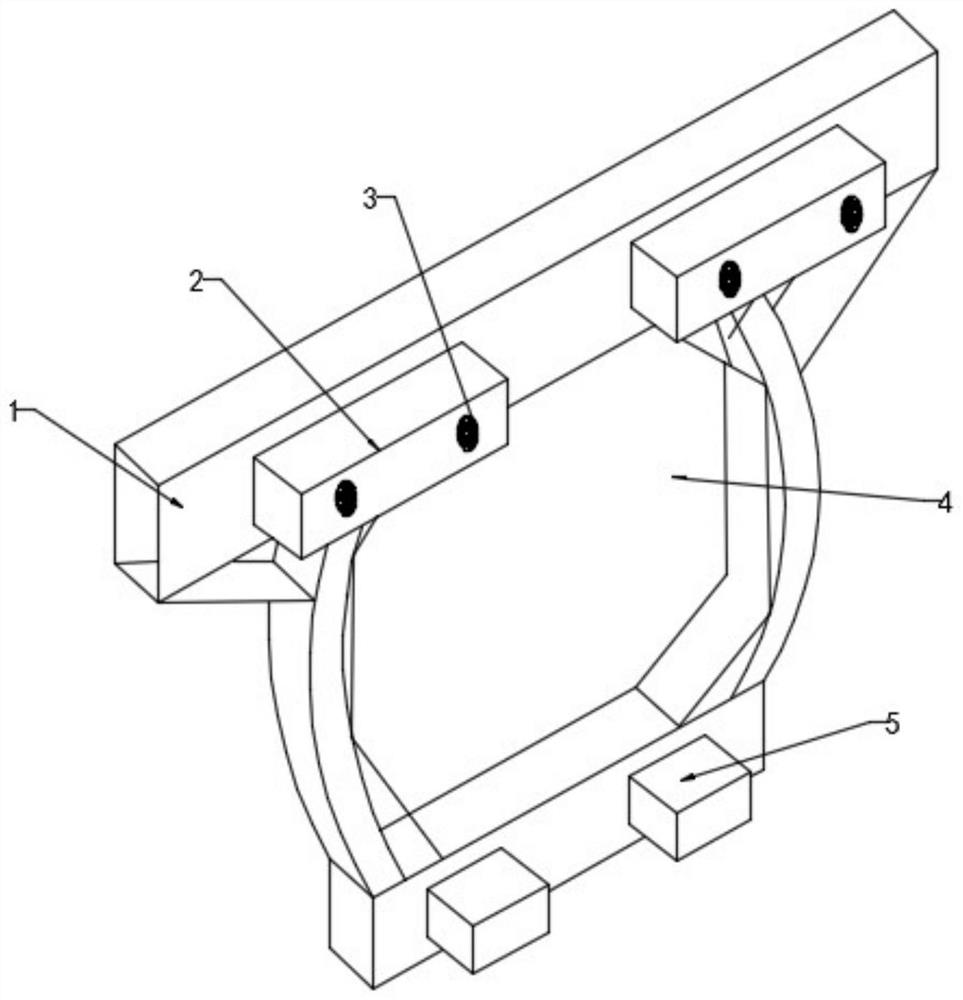

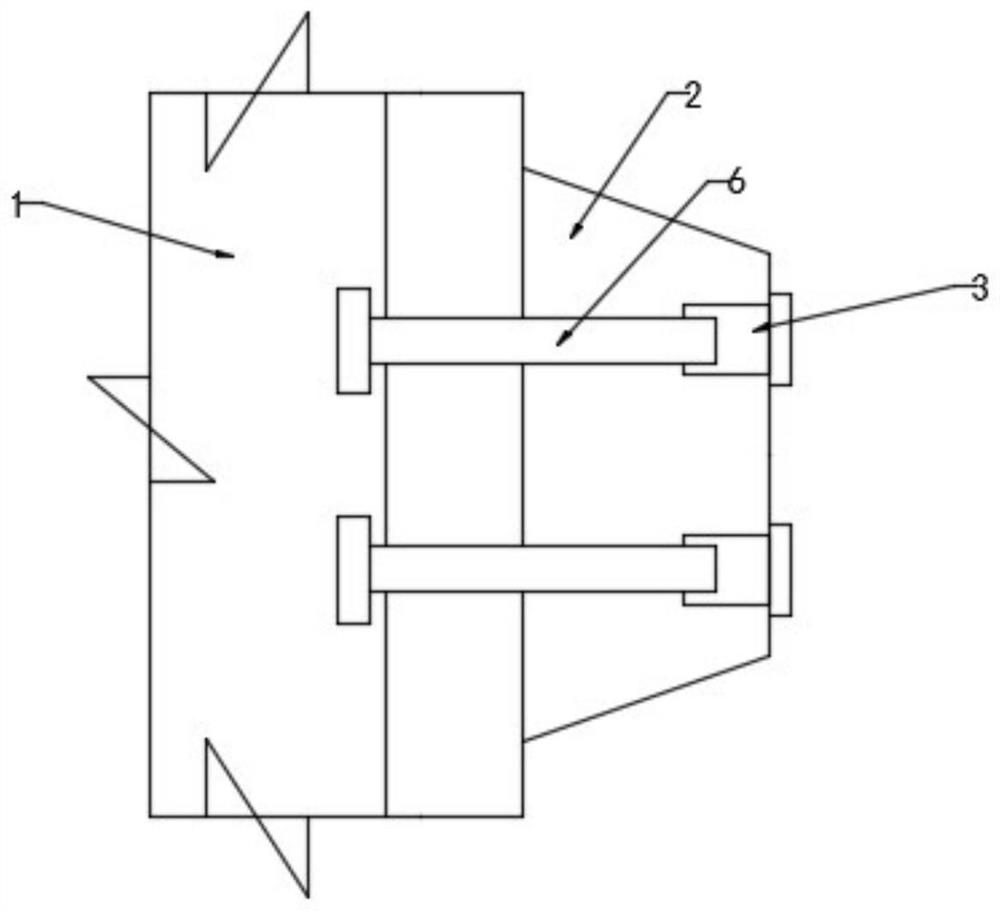

[0028] See figure 1 , In Embodiment 1 of the present invention, a segment beam end template includes: a segment beam end template body 1 for constructing a foundation of different segment beam end templates and a segment beam end template body 1 used to form Shear keys of different section beam end templates; the middle inside of the section beam end template body 1 is a template end 4, which is used to form a segment beam end; the shear keys are divided into two types, They are the first shear key 2 and the second shear key 5; the first shear key 2 and the segment beam end template body 1 are easily disassembled and assembled, and the second shear key 5 and the segment beam end template Easy to disassemble and assemble between the main body 1;

[0029] Through different types of shear keys, such as the first shear key 2, such as the second shear key 5, cooperate with the segment beam end template body 1 to form different types of segment beam end templates, and then manufacture ...

Embodiment 2

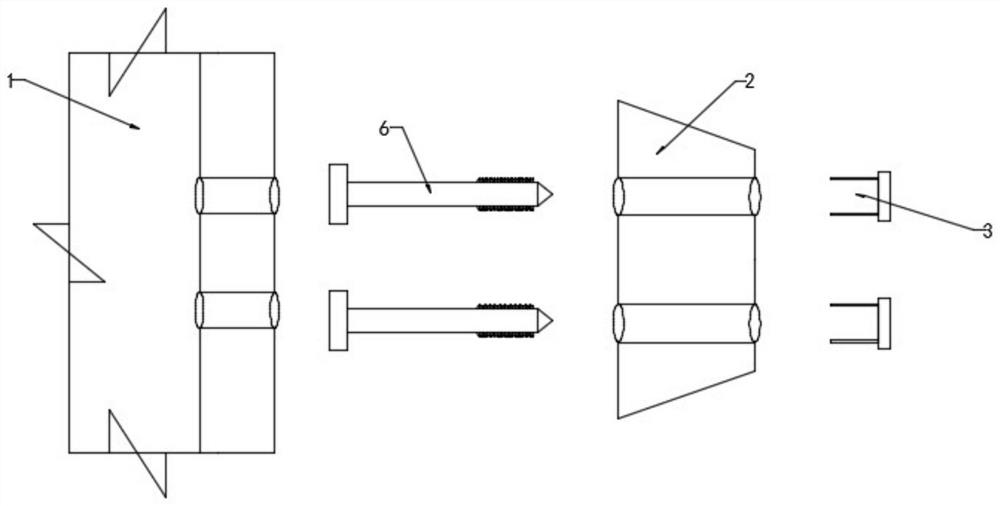

[0033] See Figure 4 with Figure 5 Further, the section beam end template body 1 and the second shear key 5 are connected and fixed by a second fixing buckle 7.

[0034] Specifically, the section beam end template body 1 is provided with a through hole on the right side, the second shear key 5 is provided with a screw 8 on the left side, and the second fixing buckle 7 is provided with internal threads;

[0035] When the segment beam end template body 1 and the second shear key 5 are assembled, the screw 8 on the side of the second shear key 5 penetrates the through hole of the segment beam end template body 1 and extends into the segment beam end template body 1 inside, then the internal thread of the second fixing buckle 7 is connected with the surface of the screw 8 by interference fit, so that the section beam end template body 1 and the second shear key 5 are assembled.

[0036] Furthermore, in order to prevent loosening between the second fixing buckle 7 and the screw 8 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com