Pillar guard board with integrated fixing aids

A technology of auxiliary device and column guard plate, which is applied in the directions of transportation and packaging, sub-assembly of superstructure, superstructure, etc., to achieve the effect of quick and simple addition and shortening of assembly time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

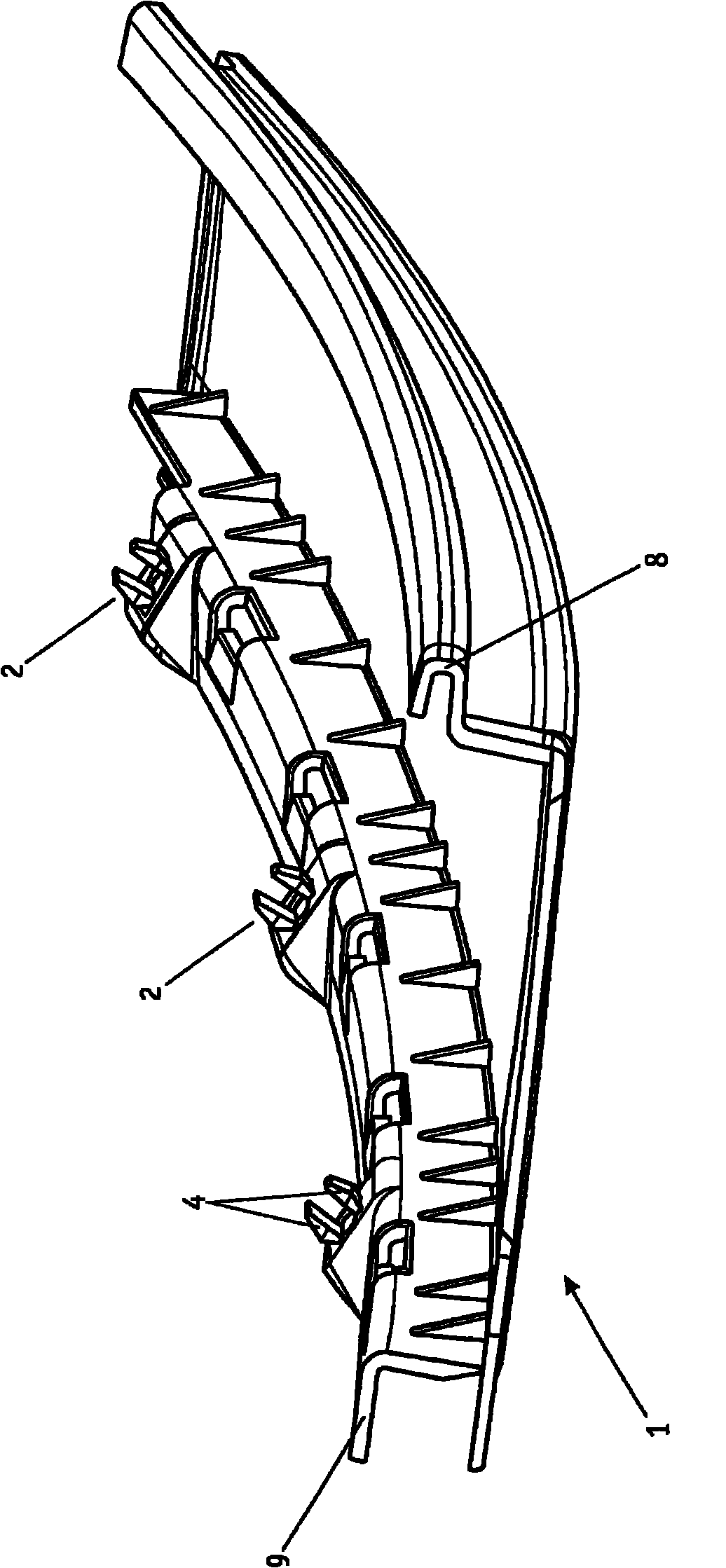

[0028] figure 1 A three-dimensional overall view of the pillar finisher 1 is shown in , which shows in particular the inner side of the pillar finisher 1 . figure 1 The pillar finisher shown in is a plastic component produced by injection molding.

[0029] In the end region, the first side edge of the pillar finisher 1 has a U-shaped retaining web 8 bent by approximately 90°, which in the installed state hooks onto a side member forming the vehicle body. Body panels on the outer edges. On the second, opposite side edge, a fastening web 9 is formed, which is designed for fastening to the vehicle body by fastening means. The fastening points are formed at a distance from one another on the fastening webs 9 , at which fastening aids 2 in the form of fastening clips are arranged, which form an integral part of the pillar finisher 1 .

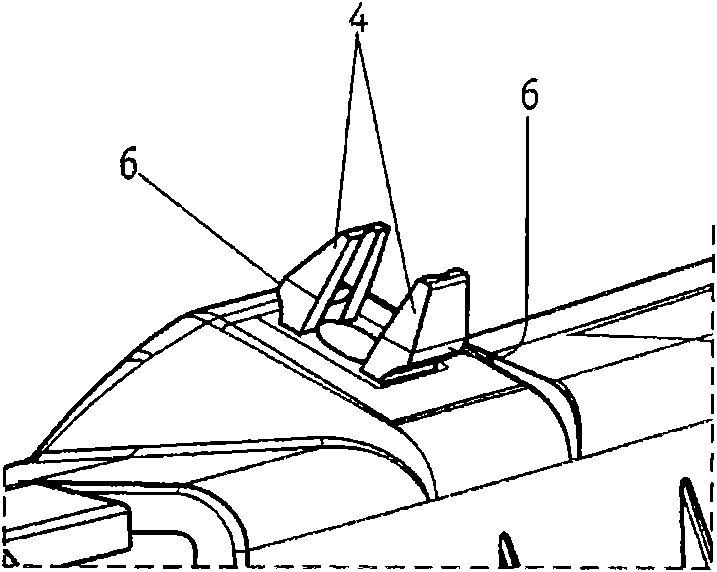

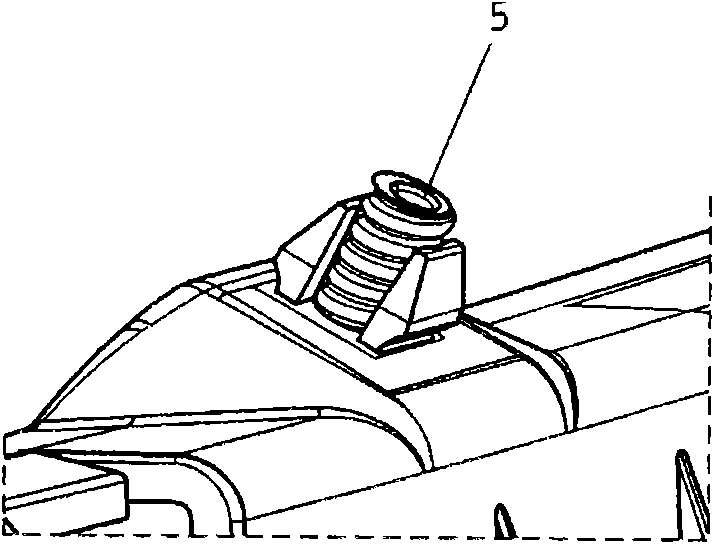

[0030]The fastening aid 2 has a tenon-like projection in the form of two clamping tabs 4 , whose inner surfaces facing one another run parallel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com