Protective device of small load sensor in series structure

A technology of load sensor and protection device, applied in measuring devices, instruments, scientific instruments, etc., can solve problems such as damage to small load sensors and large loads, and achieve the effects of low cost, accurate and reliable positioning, and small axis distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

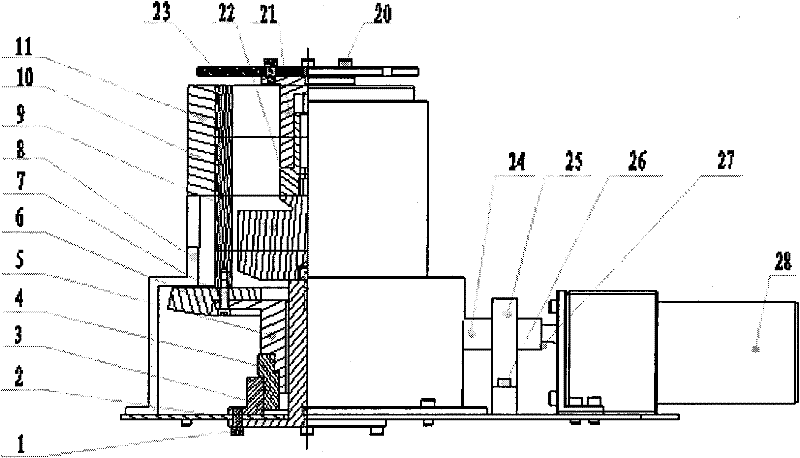

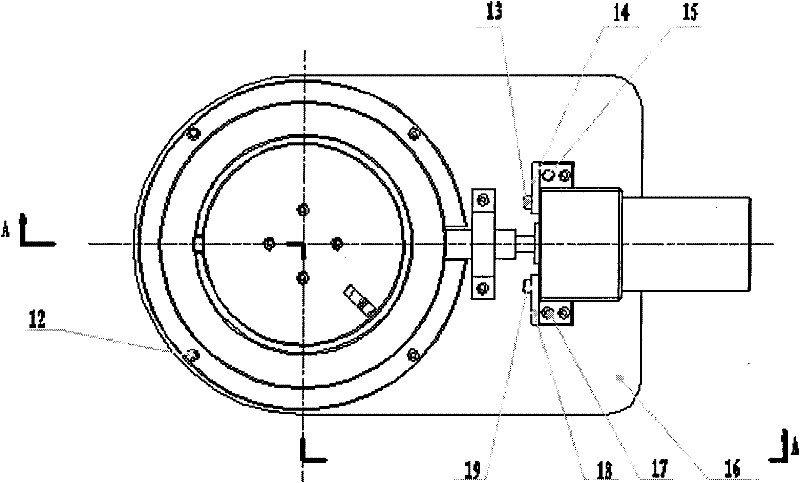

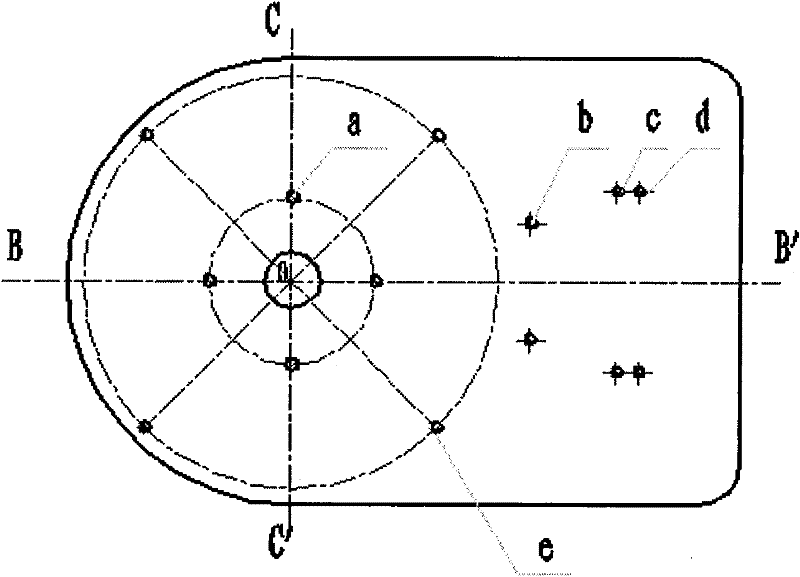

[0015] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

[0016] as attached figure 1 , 2 , 3, and 4, when assembling, first pass the DC geared motor 28, the left motor support plate 14, the right motor support plate 18, the bearing with seat 25, the support rod 2, and the bearing seat 3 through the M5 socket head cap screws and the panel 16 fasten the connection, then place the thrust ball needle roller bearing 4, the large bevel gear 6, the rotating bushing 5 and the small bevel gear 24 on the installation position, then fasten the sensor 9 on the support rod 2, and connect the small bevel gear The shaft sleeve 22 is fastened on the sensor 9, and then the inner sleeve 10 is placed on the installation position for fastening, and the sleeve 11 with a guide key and the outer sleeve 8 with a guide groove are added, and finally the small sleeve 21 is supported. Assembled on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com