Method for detecting mechanical system of drilling machine well mouth drill stem flux leakage detector

A mechanical system and detection method technology, applied in the direction of chemical instruments and methods, cleaning methods using gas flow, mechanical equipment, etc., can solve problems such as large current, increased engineering risk, and increased drilling engineering cost, and achieve the goal of using Convenient, fast and reliable connection or separation, reducing the effect of movement resistance

Inactive Publication Date: 2011-01-05

CNPC BOHAI DRILLING ENG +1

View PDF3 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The factory-type drill pipe flaw detection system has the following limitations in application: 1. The reciprocating handling of a large number of drill pipes not only affects the progress of the drilling project, but also increases the cost of the drilling project; 2. For deep wells, ultra-deep wells, offshore drilling, and off-site contracting For long-period engineering projects such as drilling, it is often difficult to send the drill pipe for inspection in time to make it run with damage, which increases the risk of the project; 3. Since the electromagnetic excitation flaw detection device requires a relatively large current, it cannot It is used in flammable and explosive occasions, such as the wellhead of a drilling rig; 4. The drill pipe must be tested for flaws in the horizontal direction, which cannot adapt to the characteristics of the vertical movement of the drill pipe when the wellhead is tripped.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

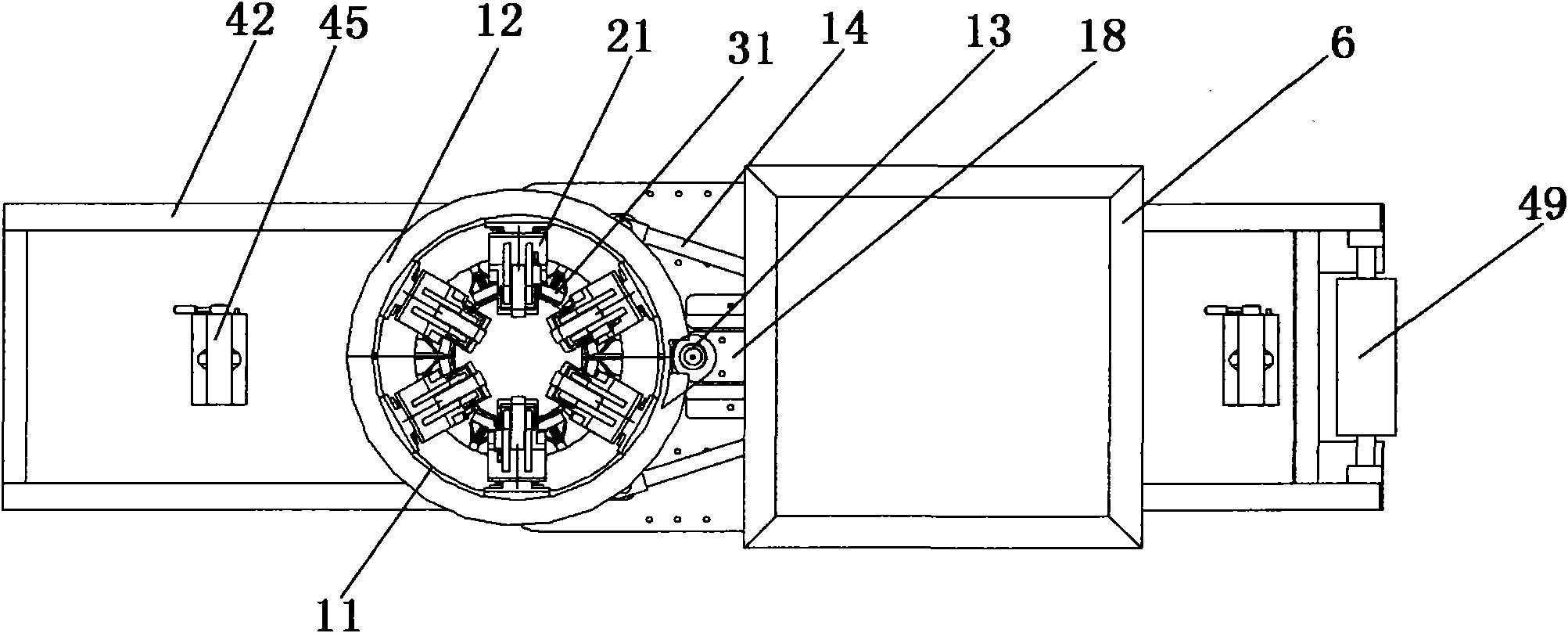

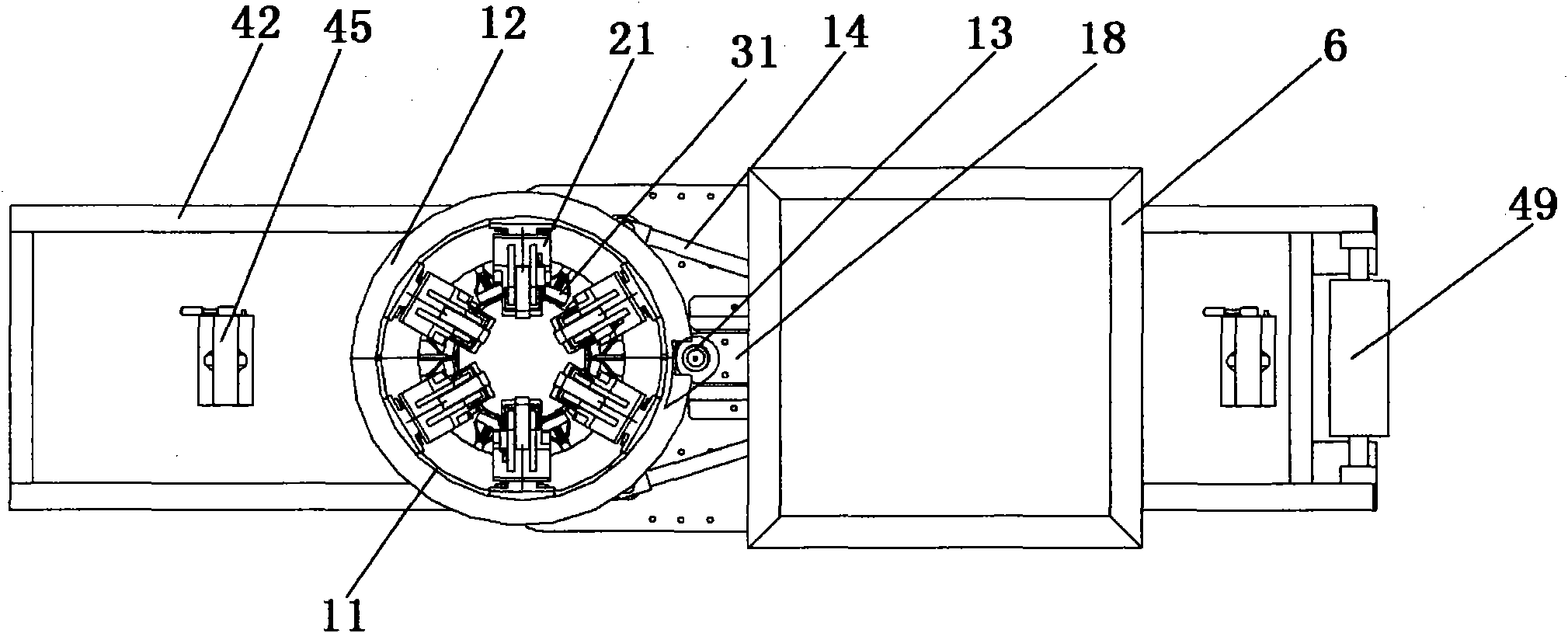

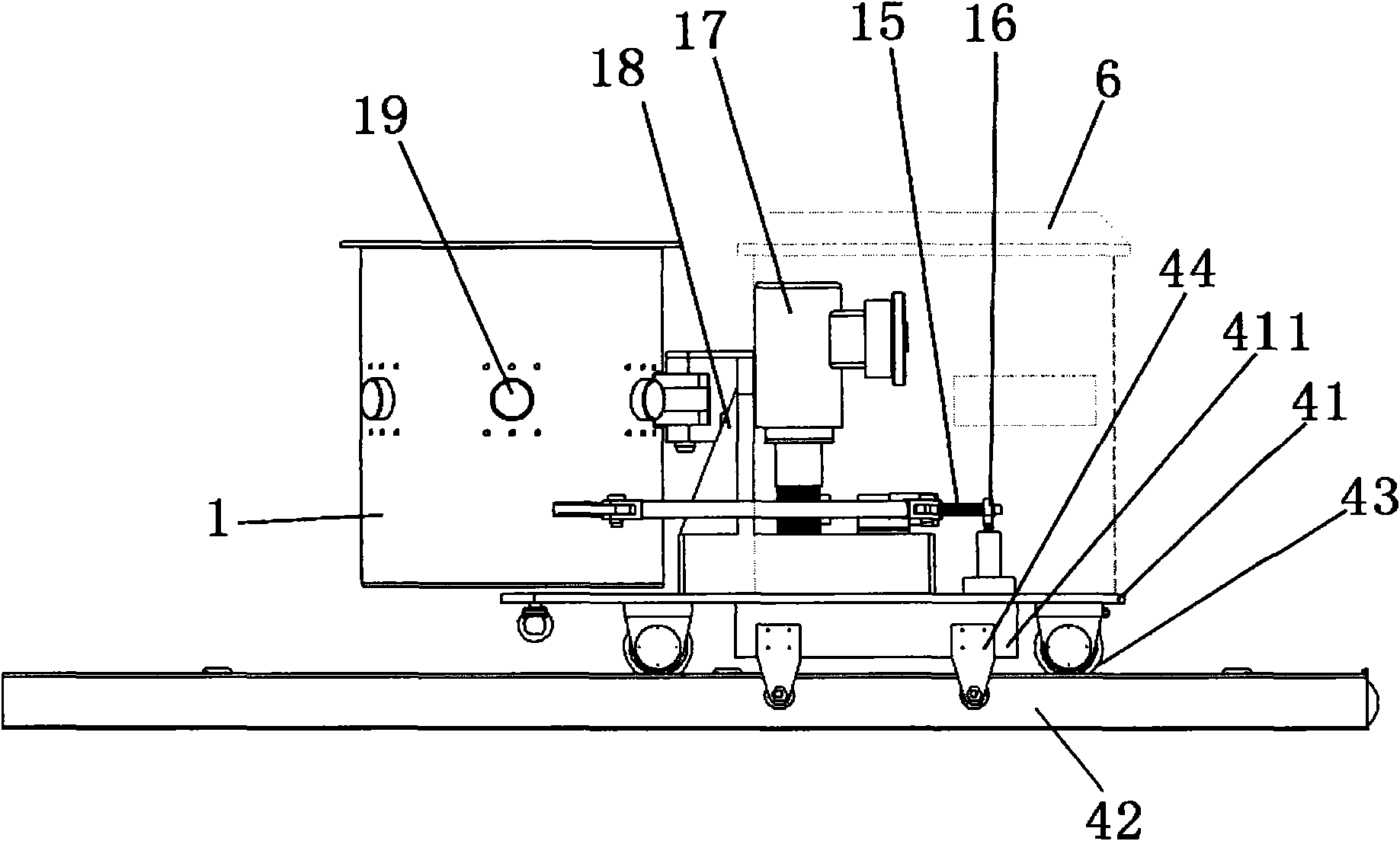

The invention discloses a method for detecting the mechanical system of a drilling machine well mouth drill stem flux leakage detector. The mechanical system comprises a clamp arm device and a permanent magnetic detector device, wherein the clamp arm device can be closed in a cylindrical shape; an accommodating part is arranged in the clamp arm device, and a detector connecting seat is arranged in the accommodating part; and the detector device is arranged on the detector connecting seat. The detection method comprises the following steps: rendering the clamp arm device in an open state and positioning the clamp arm device at the well mouth position of the drilling machine; closing the clamp arm device and placing the upper part of the drill stem at the position of the well mouth of the drilling machine in the accommodating part; lifting the drill stem along the axial direction of the drill stem, and performing the flux leakage type flaw detection of the drill stem by using the permanent magnetic detector device; and opening the clamp arm device and withdrawing the clamp arm device from the well mouth of the drilling machine. The method can detect the drill stem without current and therefore can be directly used at the well mouth of the drilling machine and used conveniently; in addition, the detector device realizes the flux leakage flaw detection in a round trip process at the well mouth of a petroleum drilling machine, the detector is safe and explosion-proof and the manual washing of the drill stem is avoided.

Description

The detection method of the mechanical system of the magnetic flux leakage detector for the drill pipe at the wellhead of the drilling rig technical field The invention relates to a detection method for a mechanical system of a drill pipe magnetic flux leakage detector at the wellhead of a drilling rig, which can detect the damage degree of the drill pipe metal on-line. Background technique During the drilling process, the drill pipe bears various loads such as tension, torsion, vibration, etc., and is subjected to severe friction and erosion of high-pressure mud, and the service conditions are very harsh. Failure to discover cracks, pits, perforations and other defects in the rod body will easily lead to major accidents such as drill pipe breakage and even wellbore scrapping. Therefore, it is necessary to perform flaw detection on the drill pipe to obtain the damage condition of the drill pipe. So far, factory-type drill pipe flaw detection systems have been widely used...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N27/83E21B37/00F16H37/00F16H25/20B08B5/02

Inventor 魏立明刘贤文李兴文陶瑞东赵福优林立谢新安刘建华宋强林洪亮赵帅元

Owner CNPC BOHAI DRILLING ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com