Thin wafer handling structure, and thin wafer bounding and releasing method

A technology of thin wafers and wafers, which is applied in the field of thin wafer processing structure and easy bonding and stripping, which can solve the problems of high stripping temperature and the influence of internal wiring configuration, etc., and achieve the effect of good chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The methods of making and using various embodiments of the present invention will be discussed in detail below. However, it is worth noting that many feasible inventive concepts provided by the present invention can be implemented in various specific ranges. These specific embodiments are only used to illustrate the manufacturing and use methods of the present invention, but are not used to limit the scope of the present invention.

[0017] The invention provides a thin wafer processing structure and method to facilitate bonding and peeling in the wafer process. In the various illustrations and embodiments disclosed in the present invention, similar signs are used to indicate similar elements.

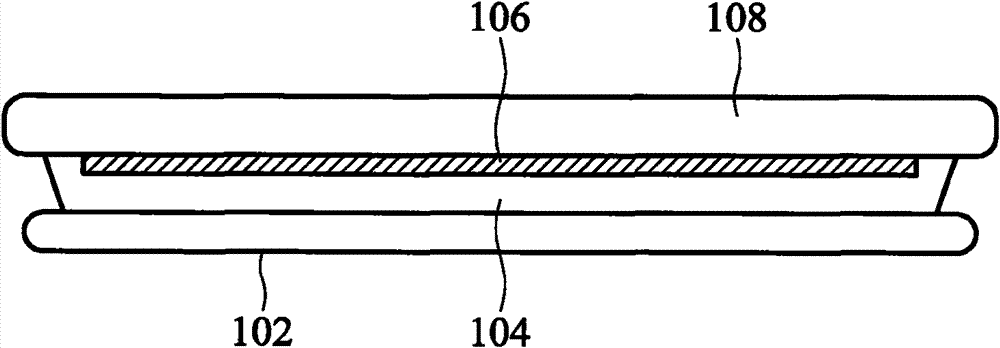

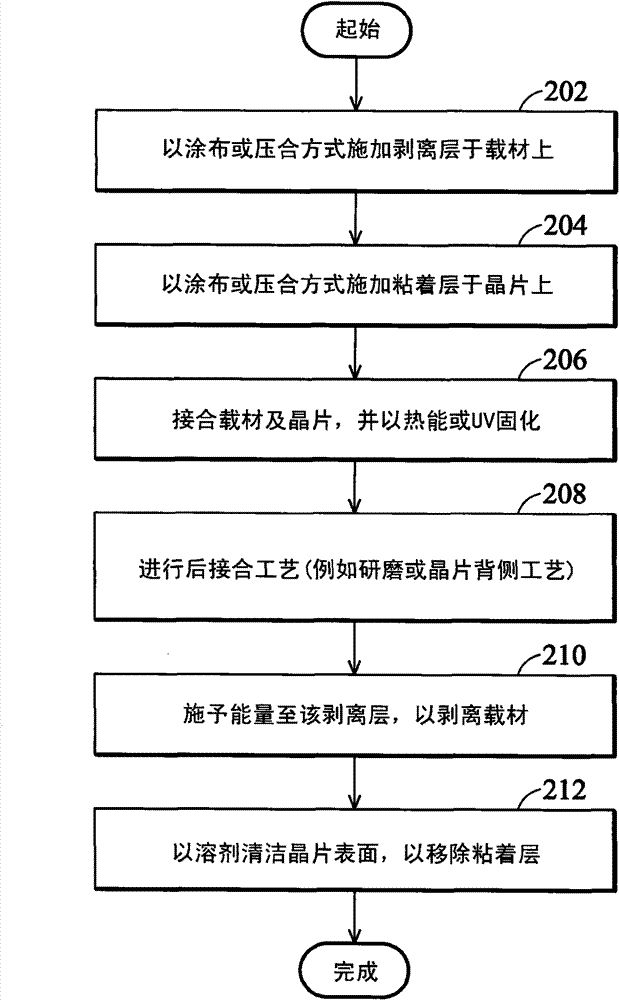

[0018] figure 1 It is shown as a thin wafer processing structure according to an embodiment of the present invention to facilitate bonding and peeling. The wafer 102 is bonded to the carrier 108 by using two film layers (ie, the peeling layer 106 and the adhesive layer 104) between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com