Glove fabric and preparing process thereof

A fabric and glove technology, applied in the field of fabrics and textile fabrics, can solve the problems of harsh environment, cotton gloves and rubber gloves cannot provide safe and reliable protection, and do not have the function of skin care, etc., to achieve good heat insulation performance, high tensile strength, The effect of high chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

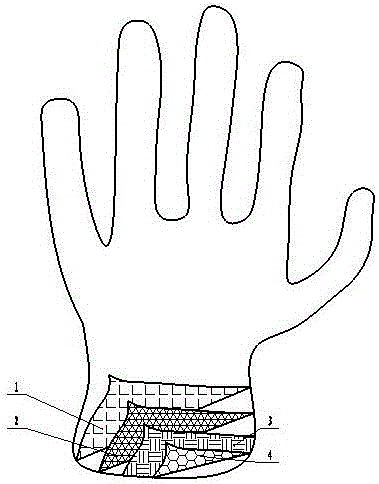

[0022] see figure 1 , a glove fabric, characterized in that: it includes an outer skin layer, and the outer skin layer is sequentially provided with a heat-insulating layer, a fixed layer and an inner inner layer; the outer skin layer is a fluorescent powder coating; the heat-insulating layer is made of glass fiber Woven; the fixed layer is woven with aramid fiber, and the inner layer is woven with polyester fiber.

[0023] A kind of preparation technology of glove fabric, is characterized in that: comprise the steps:

[0024] The first step: weave the aramid fiber according to the warp and weft, and weave the glass fiber and polyester fiber separately;

[0025] Step 2: Spread the three layers of material evenly and fix them with cotton yarn;

[0026] Step 3: Send the prepared three-layer fabric into the dipping tank. Under normal production conditions, the hand mold on the assembly line automatically enters the dipping tank and adheres;

[0027] Step 4: The three layers of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com