Long-carbon-chain polyamide, polyketone and polyphenylene sulfide alloy material and preparation method thereof

A carbon chain polyamide and polyphenylene sulfide technology, which is applied in the field of long carbon chain polyamide, polyketone and polyphenylene sulfide alloy materials and their preparation, can solve the problem of poor processability and oil resistance of polyketone, charring and carbonization , strain capacity/resilience and poor recoverability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0046] Preparation Example 1 (preparation of the long carbon chain polyamide used in the present invention):

[0047] The preparation method of described long carbon chain copolymerized nylon comprises the steps:

[0048]Salt-forming reaction: under the protection of nitrogen, dissolve 172kg of monomer B decanediamine and 230kg of monomer C dodecanedibasic acid in water, raise the temperature to 80°C, and react for 2 hours until the reaction liquid becomes a clear solution. Then add acetone to the solution, precipitate the reaction product, filter, wash the obtained filtrate with acetone, filter, and then dry at 58° C. for 24 hours to obtain product D;

[0049] Polymerization reaction: put 350kg of product D and 650kg of monomer A lauryl lactam together with deionized water or distilled water into an automatic control polymerization kettle with agitator, start stirring when the temperature in the polymerization kettle is heated to 125°C and continue to heat up, When the tempe...

Embodiment 1-4 and comparative example 1-3

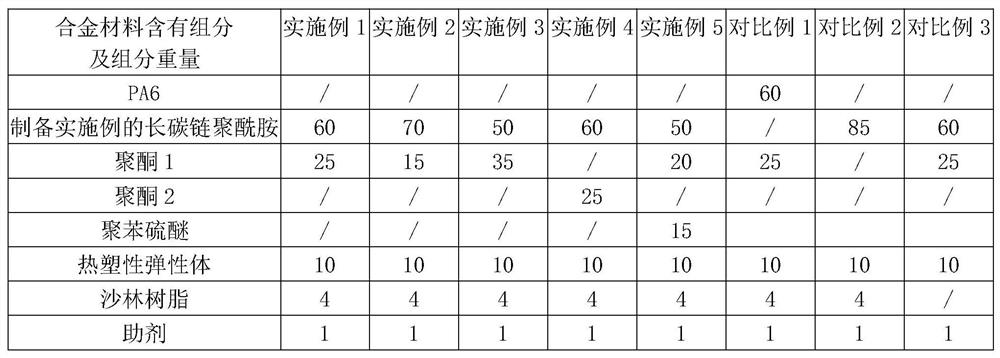

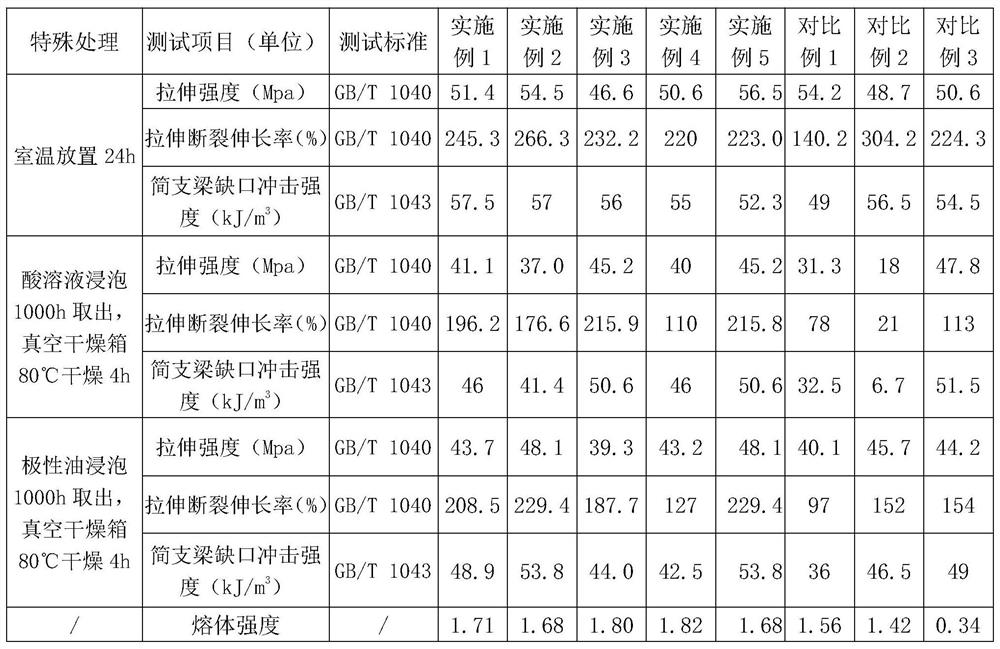

[0052] Prepare polyamide, polyketone, polyphenylene sulfide alloy according to the following method:

[0053] Step A: Add polyamide, polyketone, polyphenylene sulfide, thermoplastic elastomer, sarin resin, and additives measured according to the formula components in Table 1 to a high-speed batch mixer and mix at high speed for 10-20 minutes, mix Obtain ready-mixed mixture evenly;

[0054] Step B: Put the ready-mixed mixture into TE-75 parallel twin-screw extruder for melt extrusion, extruder zone 1, zone 2, zone 3, zone 4, zone 5, zone 6, zone 7, zone 8, zone 9, The temperature of the machine head is set to 200°C, 220°C, 220°C, 210°C, 200°C, 190°C, 160°C, 150°C, 150°C, 210°C in sequence, the temperature control error control range is ±30°C, and the speed is set to 250r / min, and the speed error control range is ±50r / min; after water cooling, pelletizing, sieving and drying, long carbon chain polyamide, polyketone and polyphenylene sulfide alloy materials are obtained.

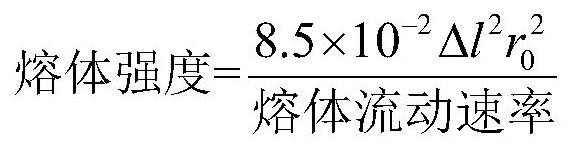

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com