A preparation method of a high-performance reverse osmosis membrane to promote the growth of polyamide nanovesicles

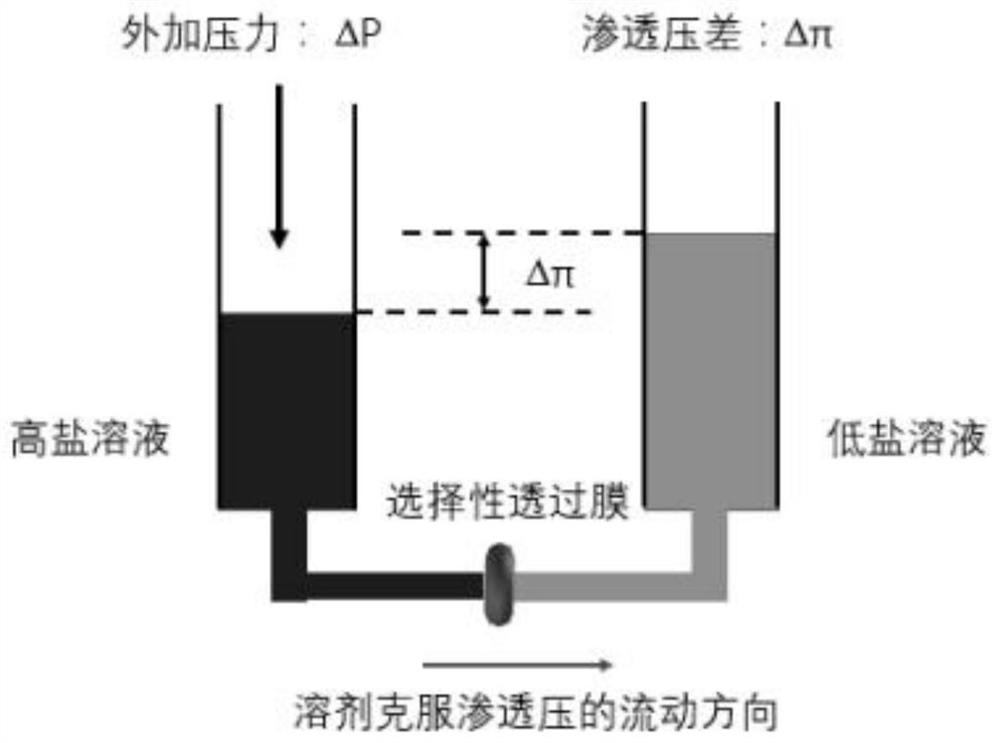

A nanovesicle, reverse osmosis membrane technology, applied in reverse osmosis, semi-permeable membrane separation, chemical instruments and methods, etc., can solve problems such as death and human dehydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

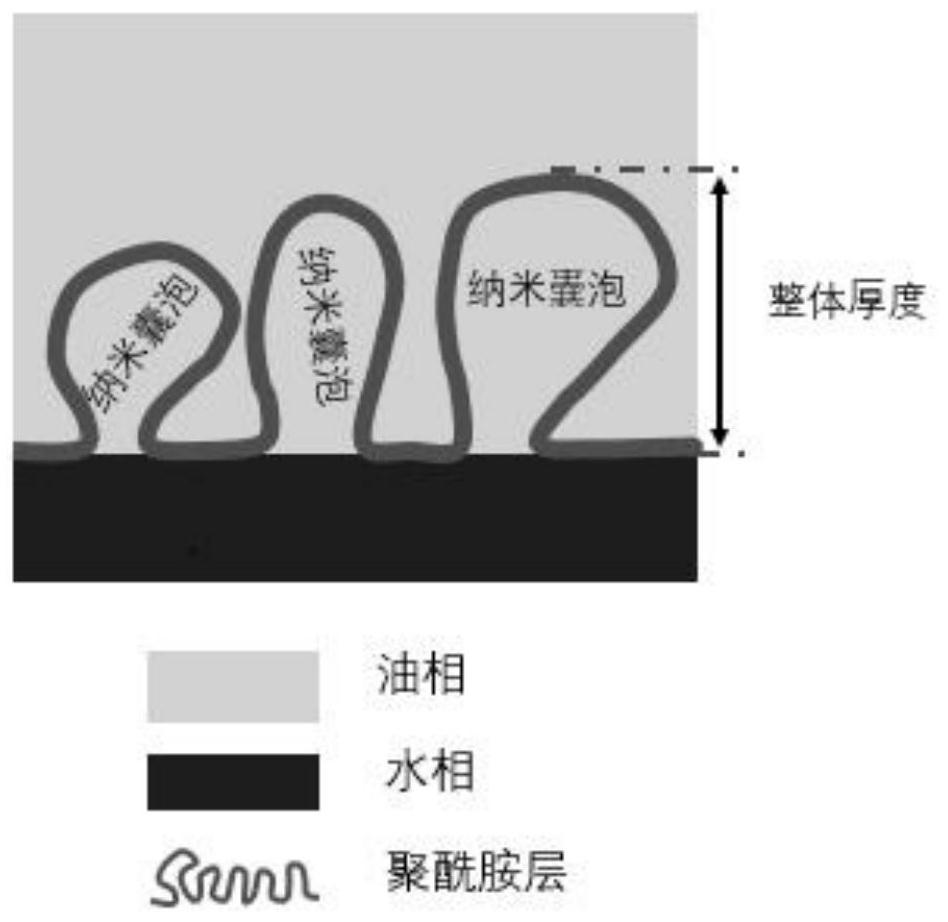

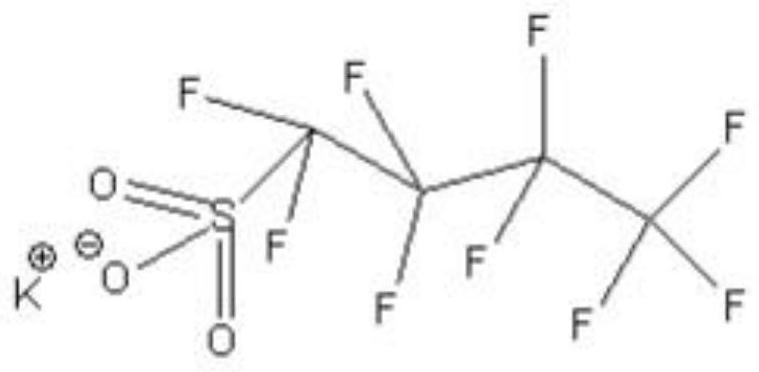

[0076] 2.2 wt% of m-phenylenediamine was dissolved in ultrapure water, 4 wt% of camphorsulfonic acid was added, and an appropriate amount of triethylamine was added to adjust the pH of the aqueous phase solution to 10.0. After adding 0.01 wt% potassium perfluorobutane sulfonate, a magnetic stirrer was used to disperse the solute molecules in the aqueous phase solution uniformly to obtain a clear aqueous phase solution. 0.11wt% trimesoyl chloride was added to the Isopar-G oil phase solvent, and it was sonicated with an ultrasonic instrument to obtain a clear and transparent oil phase solution.

[0077] Pour the above-prepared aqueous phase solution on the surface of the polysulfone ultrafiltration membrane, let it stand for 2 minutes, pour off the excess water phase on the surface of the polysulfone ultrafiltration membrane, and use a nitrogen air knife to purge the surface of the polysulfone ultrafiltration membrane to remove Water drops and droplets. Subsequently, the above ...

Embodiment 2

[0079] The preparation steps of the membrane were repeated in Example 1, the only difference being that "during the preparation of the aqueous phase solution, the concentration of potassium perfluorobutanesulfonate was replaced by 0.05wt%", and the rest of the steps were the same as in Example 1, and the final preparation A polyamide reverse osmosis membrane is obtained. The film number is designated as M-0.05.

Embodiment 3

[0081] The preparation steps of the membrane were repeated in Example 1, the only difference being that "during the preparation of the aqueous phase solution, the concentration of potassium perfluorobutane sulfonate was replaced by 0.1 wt%", and the rest of the steps were the same as in Example 1, and the final preparation A polyamide reverse osmosis membrane is obtained. The film number is designated as M-0.1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com