Device and method for correcting spatially-downwarped steel beam

A steel beam, space technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0012] Example: Correction of downward deflection of group steel beams at the bottom of a gas vertical furnace.

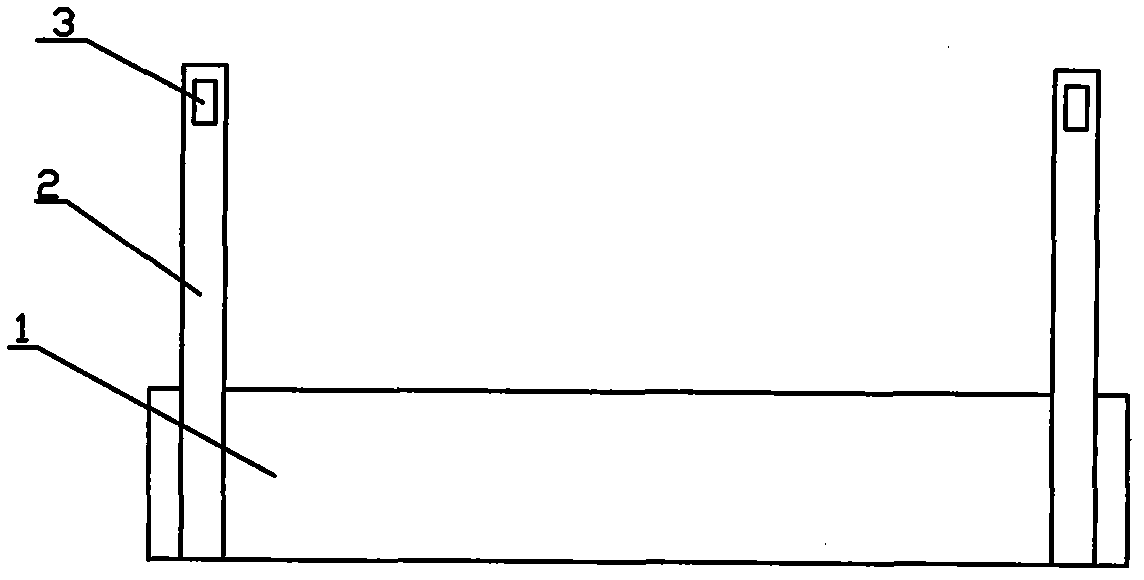

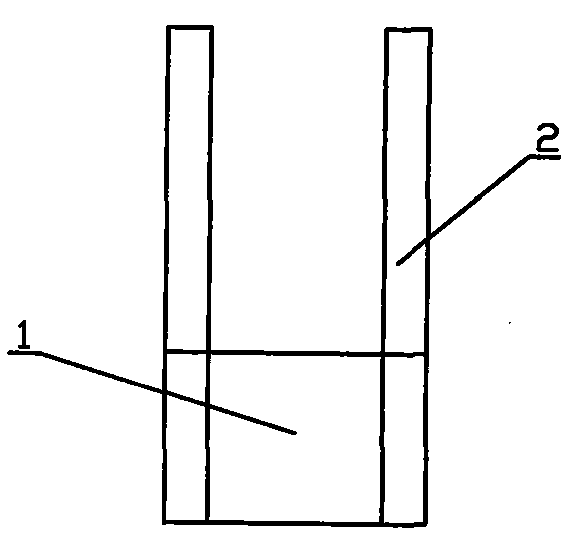

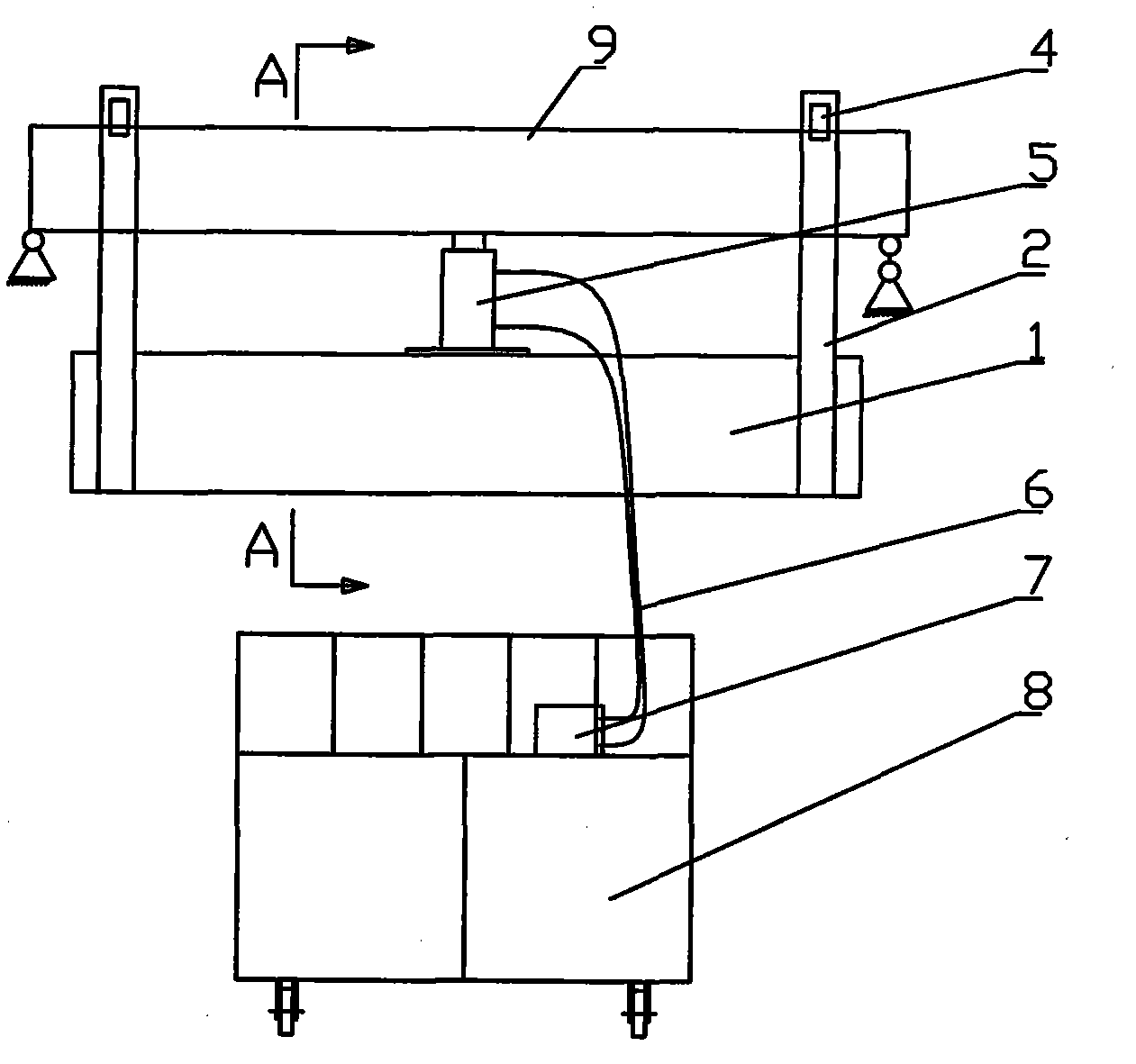

[0013] Referring to the accompanying drawings, the basic shape of the steel beam 9 to be corrected is an I-shaped, the total height is 600mm, the upper and lower flanges are 200mm wide, 30mm thick, and 20mm thick; It includes a box beam 1, the box beam 1 is all made of 20mm steel plate, and a pair of hanging arm groups 2 with rectangular holes 3 on the upper part are welded to both ends of the box beam 1. The correction method is: use a hoisting tool to hang the box beam 1 directly below the steel beam 9 to be corrected, lift the box beam 1 up, and insert the hanging arm group 2 on the box beam 1 into the steel beam 9 to be corrected. On both sides, clamp the steel beam 9 between the two hanging arms of each hanging arm group, insert hanging pins 4 into the rectangular holes 3 of the two hanging arms of each hanging arm group, and hang the box beam 1 Below the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com