Aqueous conducting anti-corrosive paint containing nano core-shell structure polypyrrole

A nano-core-shell, conductive anti-corrosion technology, applied in conductive coatings, anti-corrosion coatings, coatings, etc., can solve the problems that polypyrrole cannot be melted, the coating is not easy to color, and the mechanical properties are poor, which is conducive to market promotion and easy to operate , Excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1: Preparation of a water-based conductive anti-corrosion coating containing polypyrrole with nano-core-shell structure

[0036] Proceed as follows:

[0037] (1) Preparation of nanoscale iodine-doped polypyrrole:

[0038] 1. Add 200 g of distilled water, 10.2 g of cationic surfactant cetyltrimethylammonium bromide (CTAB) and 6 g of co-surfactant n-amyl alcohol into a three-necked flask at room temperature, and magnetically stir to form a surfactant gel. Beam solution;

[0039] ② Add 4 g of pyrrole monomer dropwise into a three-necked flask, and continue magnetic stirring to form a micellar solution of surfactant containing pyrrole monomer;

[0040] ③Add 1.4g iodine elemental substance to the three-necked flask, and continue magnetic stirring;

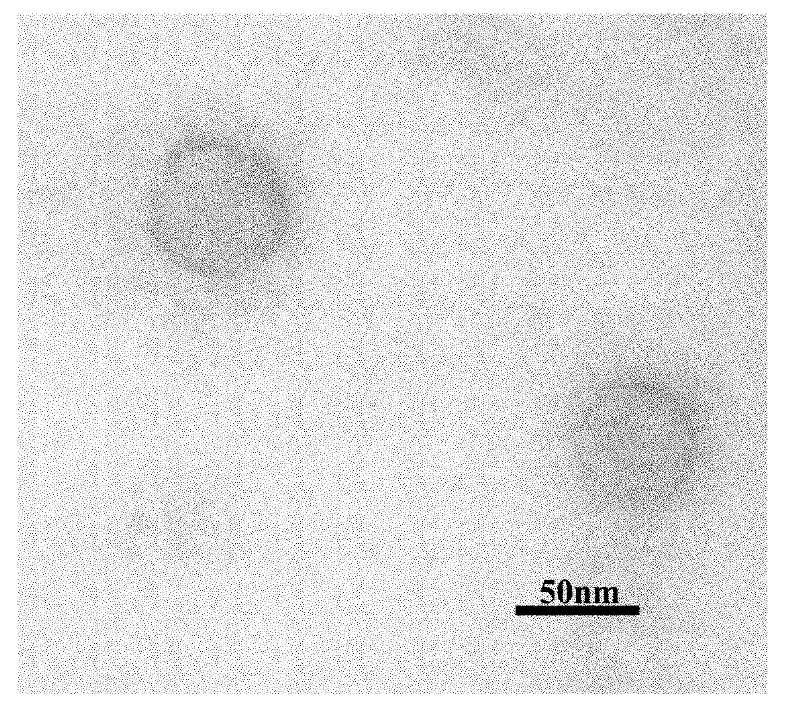

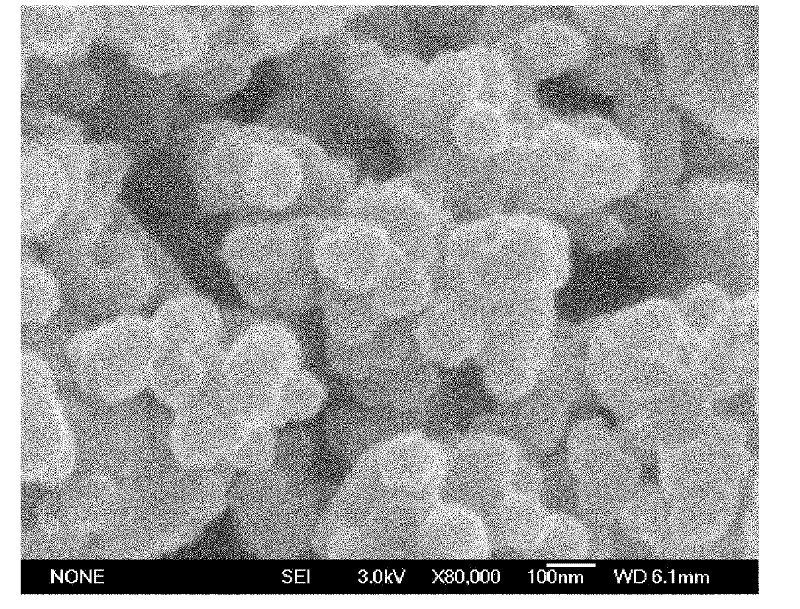

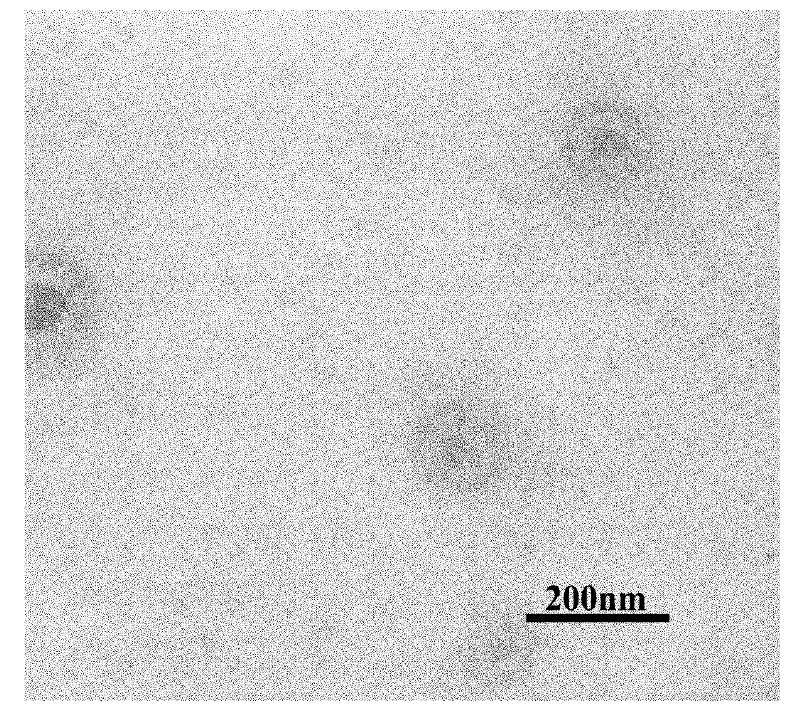

[0041] ④ Slowly add 20.4g FeCl dropwise to the three-necked flask 3 (dissolved in 40g distilled water), magnetically stirred for 3h to obtain iodine-doped nano polypyrrole, and its transmission electron microscope pho...

Embodiment 2

[0046] Example 2: Preparation of a water-based conductive anticorrosion coating containing polypyrrole with nano-core-shell structure

[0047] Proceed as follows:

[0048] (1) Preparation of nanoscale iodine-doped polypyrrole:

[0049] 1. Add 200 g of distilled water, 6.8 g of cationic surfactant cetyltrimethylammonium bromide (CTAB) and 4 g of co-surfactant n-amyl alcohol in a three-necked flask at room temperature, and magnetically stir to form surfactant gel. Beam solution;

[0050] ② Add 2 g of pyrrole monomer dropwise into a three-necked flask, and continue magnetic stirring to form a micellar solution of surfactant containing pyrrole monomer;

[0051] ③Add 0.6g iodine elemental substance to the three-necked flask, and continue magnetic stirring;

[0052] ④ Slowly add 7.8g FeCl dropwise to the three-necked flask 3 (dissolved in 40 g of distilled water), and magnetically stirred for 3 hours to obtain iodine-doped nano-polypyrrole.

[0053] ⑤Add 5g of methyl methacryla...

Embodiment 3

[0057] Example 3: Preparation of a water-based conductive anti-corrosion coating containing polypyrrole with nano-core-shell structure

[0058] Proceed as follows:

[0059] (1) Preparation of nanoscale iodine-doped polypyrrole:

[0060] 1. Add 200 g of distilled water, 13.6 g of cationic surfactant cetyltrimethylammonium bromide (CTAB) and 8 g of co-surfactant n-amyl alcohol in a three-necked flask at room temperature, and magnetically stir to form surfactant gel. Beam solution;

[0061] ② Add 6 g of pyrrole monomer dropwise into a three-necked flask, and continue magnetic stirring to form a micellar solution of surfactant containing pyrrole monomer;

[0062] ③Add 2.4g iodine elemental substance to the three-necked flask, and continue magnetic stirring;

[0063] ④ Slowly add 37.2g FeCl dropwise to the three-necked flask 3 (dissolved in 40 g of distilled water), and magnetically stirred for 3 hours to obtain iodine-doped nano-polypyrrole.

[0064] ⑤Add 8.96g of methyl meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com