Lithium and sodium ion battery flame retardant and preparation and application methods thereof

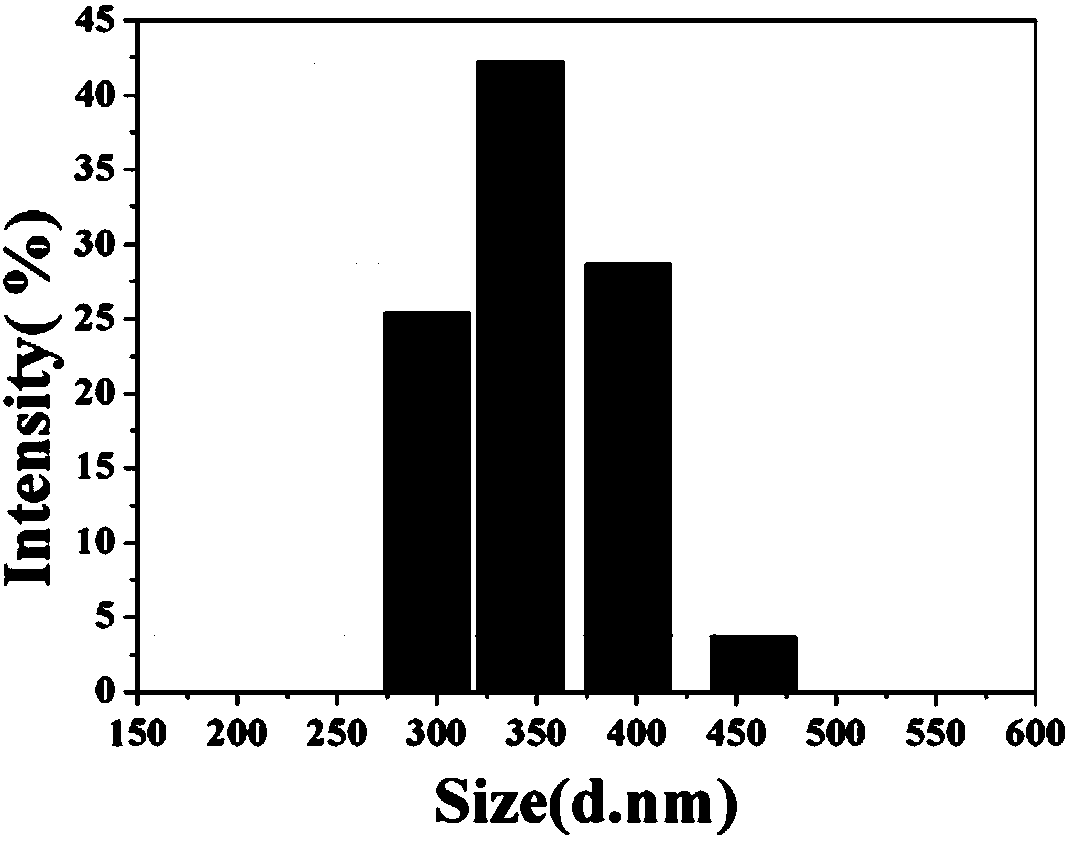

A sodium-ion battery, flame retardant technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of high price, wide particle size distribution, rapid battery temperature rise, etc., and achieve low production cost, uniform particle size, Good flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Preparation of Al2O3 Flame Retardant by Alternating Current Electrochemical Method

[0038] Immerse the aluminum / graphite rod as the working electrode in 200mL of 2.5mol / L sodium nitrate electrolyte solution, the immersion area is 4cm 2 . Then set the AC voltage to 8V and the frequency to 50Hz for electrolysis. After the electrolysis is finished, the electrolyzed product is centrifuged, washed, dried and collected. Finally, under the protection of argon, the dried electrolyte was placed in a tube furnace and calcined at 450 °C for 2 h with a heating rate of 2 °C / min.

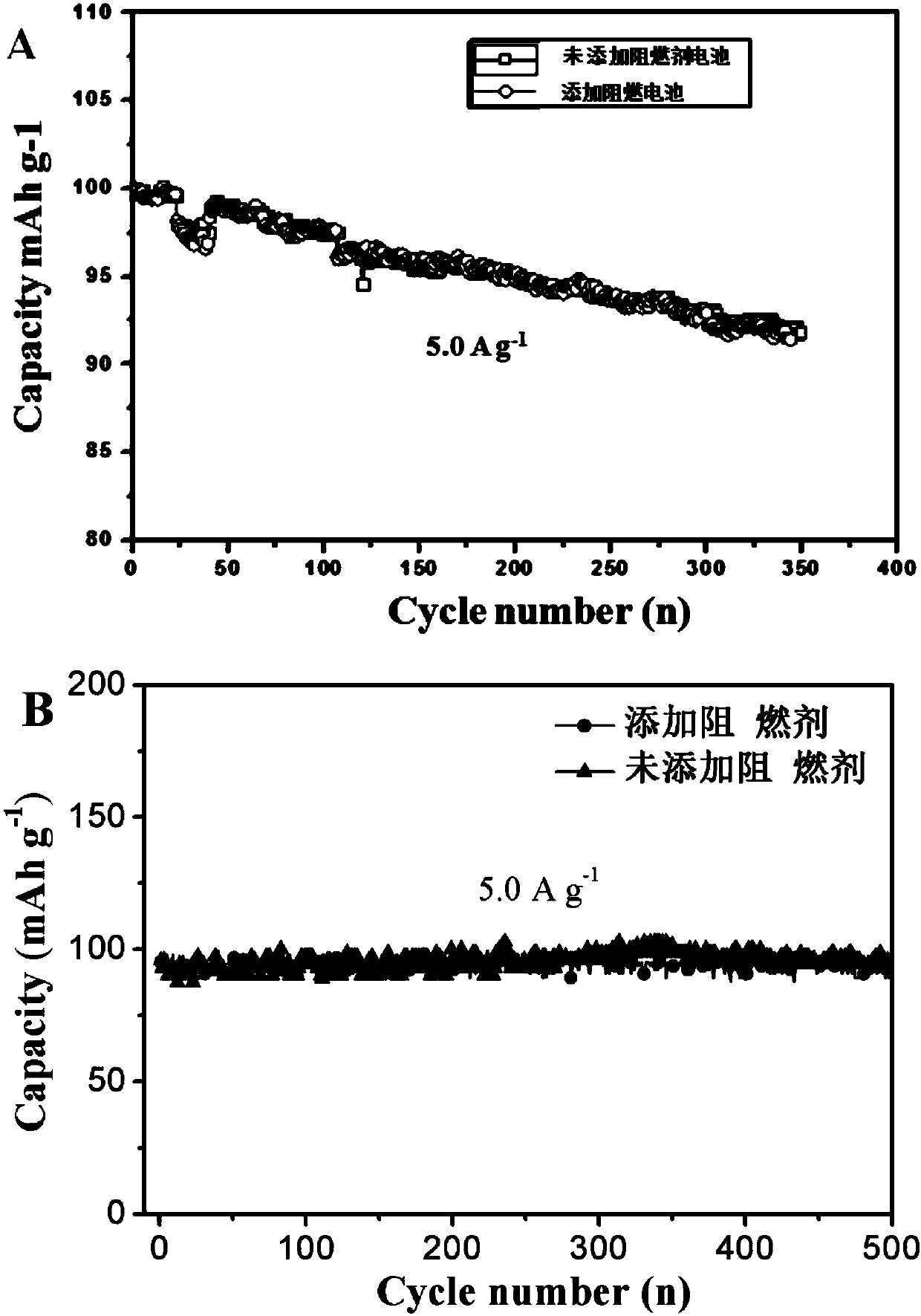

[0039] (2) Application of the prepared aluminum oxide flame retardant in lithium and sodium ion batteries

[0040] Respectively with 1.0mol / L LiPF 6 / EC+DMC (volume ratio 1:1) and 1.0mol / L NaClO 4 / PC solution is used as the reference electrolyte for lithium and sodium ion batteries. In a nitrogen-filled glove box, add Al per milliliter of Li-ion battery reference electrolyte 2 o 3 The quality...

Embodiment 2

[0046] (1) Preparation of Al2O3 Flame Retardant by Alternating Current Electrochemical Method

[0047] Immerse aluminum / platinum as a working electrode in 500mL of 1.75mol / L ammonium sulfate electrolyte solution, with an immersion area of 20cm 2 . Then set the AC voltage to 2.5V and the frequency to 70Hz for electrolysis. After the electrolysis is finished, the electrolyzed product is centrifuged, washed, dried and collected. Finally, under the protection of argon, the dried electrolyte was placed in a tube furnace and calcined at 500 °C for 6 h with a heating rate of 5 °C / min.

[0048] (2) Application of the prepared aluminum oxide flame retardant in lithium and sodium ion batteries

[0049] Respectively with 1.0mol / L LiPF 6 / EC+DMC (volume ratio 1:1) and 1.0mol / L NaClO 4 / PC solution is used as the reference electrolyte for lithium and sodium ion batteries. In a nitrogen-filled glove box, add Al per milliliter of Li-ion battery reference electrolyte 2 o 3 The quali...

Embodiment 3

[0054] (1) Preparation of Al2O3 Flame Retardant by Alternating Current Electrochemical Method

[0055] Immerse aluminum / aluminum as a working electrode in 800mL 0.75mol / L potassium carbonate electrolyte solution, with an immersion area of 60cm 2 . Then set the AC voltage to 18V and the frequency to 120Hz for electrolysis. After the electrolysis is finished, the electrolyzed product is centrifuged, washed, dried and collected. Finally, under the protection of argon, the dried electrolyte was placed in a tube furnace and calcined at 800 °C for 12 h with a heating rate of 8 °C / min.

[0056] (2) Application of the prepared aluminum oxide flame retardant in lithium and sodium ion batteries

[0057] Respectively with 1.0mol / L LiPF 6 / EC+DMC (volume ratio 1:1) and 1.0mol / L NaClO 4 / PC solution is used as the reference electrolyte for lithium and sodium ion batteries. In a nitrogen-filled glove box, add Al per milliliter of Li-ion battery reference electrolyte 2 o 3 The qual...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com