Aqueous conducting anti-corrosive paint containing nano core-shell structure polypyrrole

A nano core-shell, conductive anti-corrosion technology, applied in conductive coatings, anti-corrosion coatings, coatings, etc., can solve the problems of polypyrrole inability to melt, poor mechanical properties, difficult processing and molding, etc., to facilitate market promotion and reduce production costs , the effect of high application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1: Preparation of a water-based conductive anti-corrosion coating containing nano-core-shell polypyrrole

[0036] Proceed as follows:

[0037] (1) Preparation of nano-scale iodine-doped polypyrrole:

[0038] ①Add 200g of distilled water, 10.2g of cationic surfactant cetyltrimethylammonium bromide (CTAB), 6g of co-surfactant n-amyl alcohol into a three-necked flask at room temperature, and magnetically stir to form a surfactant glue bundle solution;

[0039] ② Add 4 g of pyrrole monomer dropwise into the three-necked flask, and continue magnetic stirring to form a micelle solution of surfactant containing pyrrole monomer;

[0040] 3. Add 1.4g of iodine element to the three-necked flask, and continue magnetic stirring;

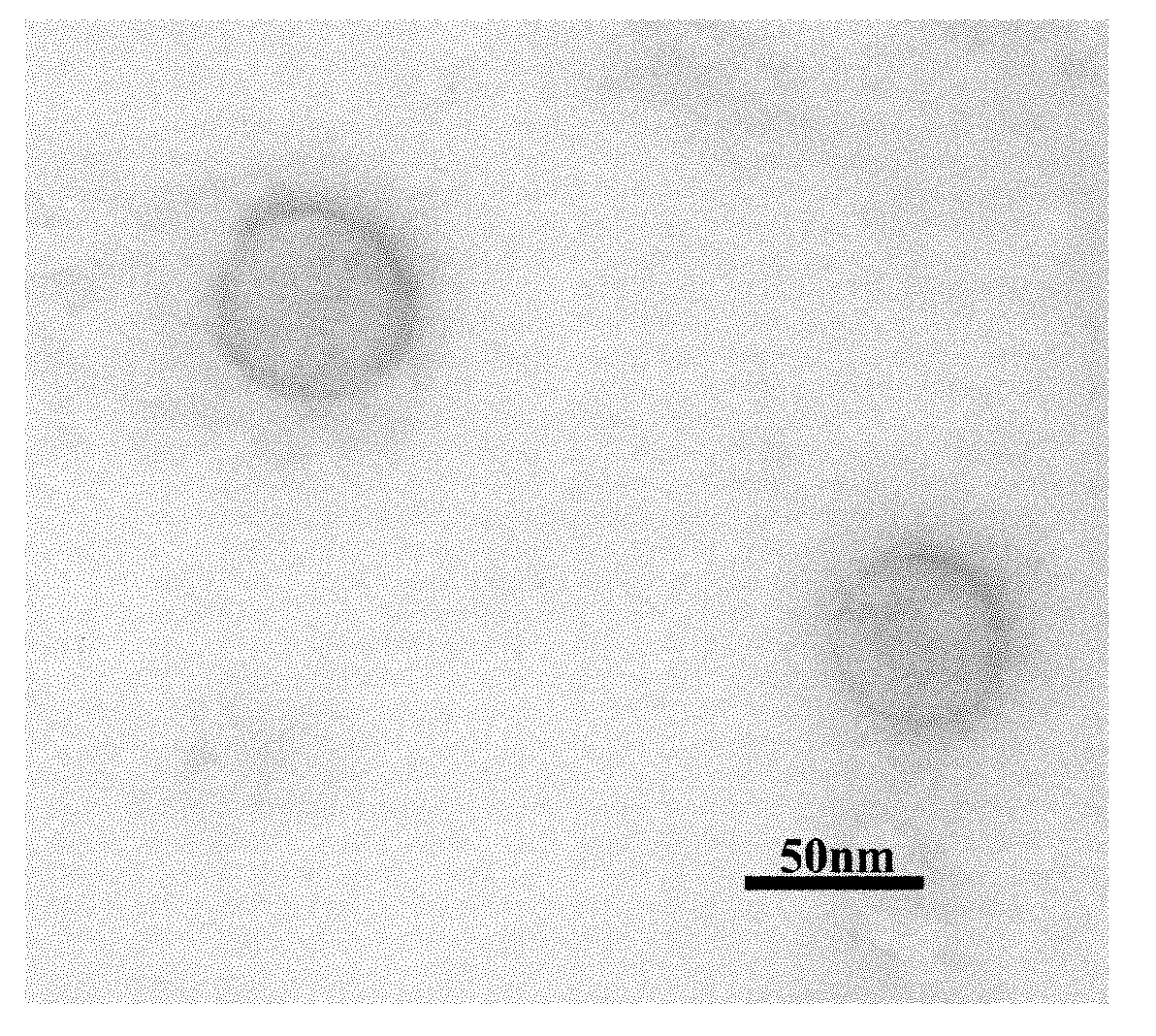

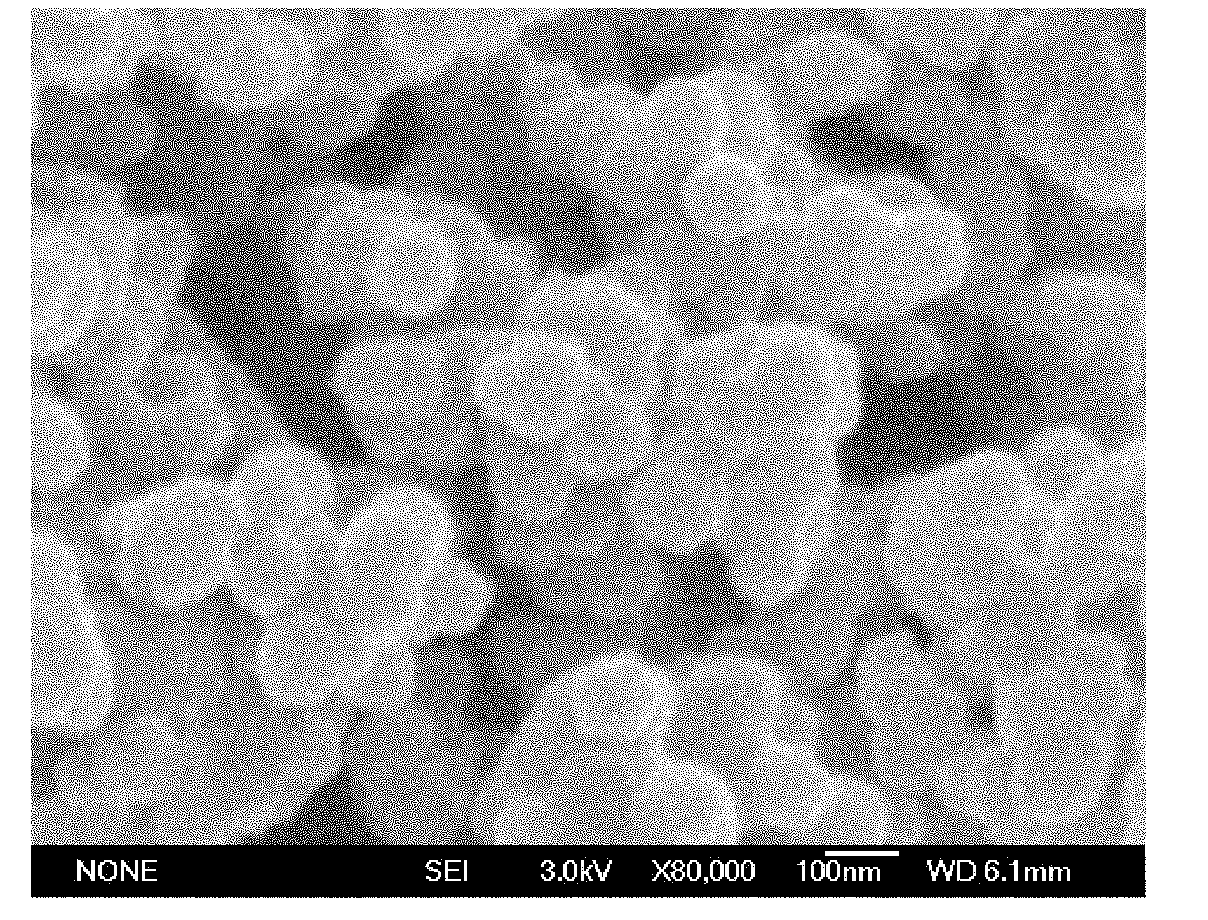

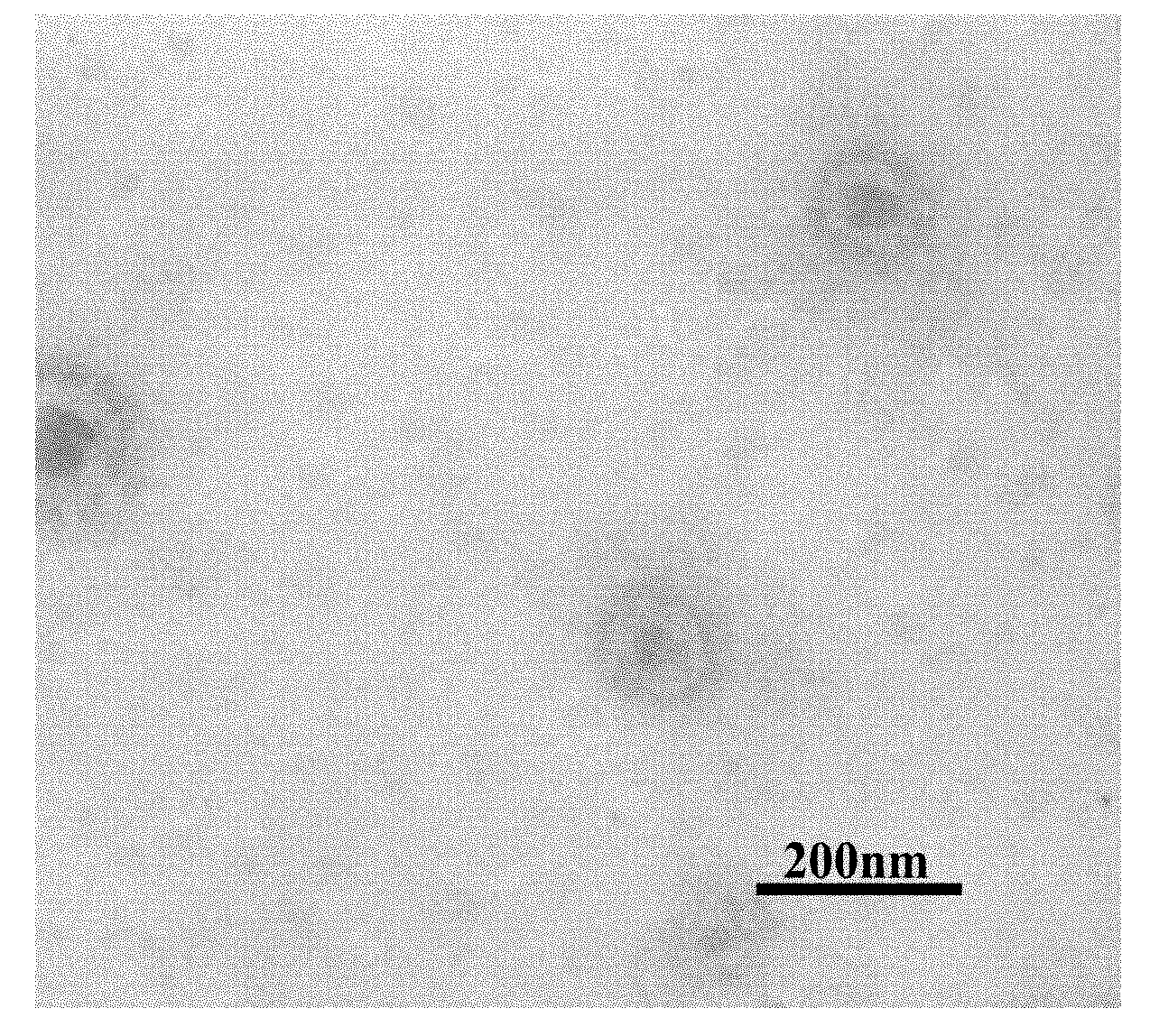

[0041] ④ Slowly add 20.4g FeCl dropwise to the three-necked flask 3 (dissolved in 40g distilled water), magnetic stirring for 3h, iodine-doped nano-polypyrrole can be obtained, and its transmission electron microscope photo is as follows figu...

Embodiment 2

[0046] Example 2: Preparation of a water-based conductive anti-corrosion coating containing nano-core-shell polypyrrole

[0047] Proceed as follows:

[0048] (1) Preparation of nano-scale iodine-doped polypyrrole:

[0049] ①Add 200g of distilled water, 6.8g of cationic surfactant cetyltrimethylammonium bromide (CTAB), 4g of co-surfactant n-amyl alcohol into a three-necked flask at room temperature, and magnetically stir to form a surfactant glue bundle solution;

[0050] ② Add 2 g of pyrrole monomer dropwise into the three-necked flask, and continue magnetic stirring to form a micelle solution of surfactant containing pyrrole monomer;

[0051] ③ Add 0.6g of iodine element to the three-necked flask, and continue magnetic stirring;

[0052] ④ Slowly add 7.8g FeCl dropwise to the three-necked flask 3 (dissolved in 40 g of distilled water) and magnetically stirred for 3 h to obtain iodine-doped nano-polypyrrole.

[0053] 5. Add 5 g of methyl methacrylate (MMA) to the three-ne...

Embodiment 3

[0057] Example 3: Preparation of a water-based conductive anti-corrosion coating containing nano-core-shell polypyrrole

[0058] Proceed as follows:

[0059] (1) Preparation of nano-scale iodine-doped polypyrrole:

[0060] ①Add 200g of distilled water, 13.6g of cationic surfactant cetyltrimethylammonium bromide (CTAB), 8g of co-surfactant n-amyl alcohol into a three-necked flask at room temperature, and magnetically stir to form a surfactant glue bundle solution;

[0061] ② Add 6g of pyrrole monomer dropwise into the three-necked flask, and continue magnetic stirring to form a micelle solution of surfactant containing pyrrole monomer;

[0062] 3. Add 2.4g of iodine element to the three-necked flask, and continue magnetic stirring;

[0063] ④ Slowly add 37.2g FeCl dropwise to the three-necked flask 3 (dissolved in 40 g of distilled water) and magnetically stirred for 3 h to obtain iodine-doped nano-polypyrrole.

[0064] 5. Add 8.96 g of methyl methacrylate (MMA) to the thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com