Three-axle single-box multi-gear automobile transmission

An automobile transmission, single-box technology, applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of inflexible transmission, long transmission assembly length, complex structure, etc., to achieve flexible transmission, axial The effect of short size and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

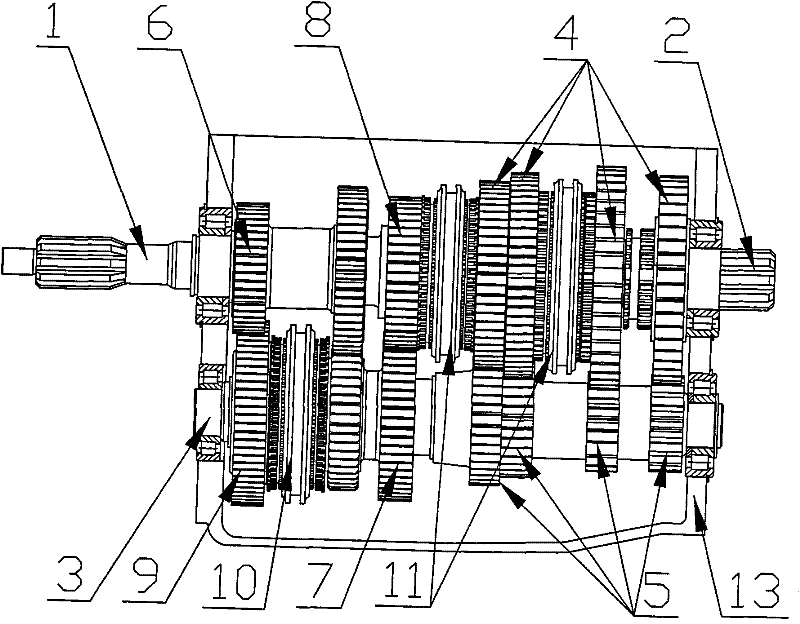

[0009] Embodiment 1 A three-shaft single-box multi-speed automobile transmission with dual gears on one shaft

[0010] Such as figure 1 Shown, a kind of three-shaft type single case multi-speed automobile transmission is characterized in that: comprise main case 13, first shaft 1, two shafts 2 and intermediate shaft 3, be single case three shaft type (not including reverse gear shaft), Two-axis idler gear 4 and synchronizer 11 are installed on the two-axis 2, and intermediate shaft fixed gear 5 and intermediate shaft idler gear 9 are installed on the intermediate shaft 3, and the two-axis idler gear 4 and intermediate shaft fixed gear 5 are meshed with each other for transmission For torque, a one-shaft double gear 6 is emptied on the first shaft 1, and an intermediate shaft double gear 7 is emptied on the intermediate shaft 3, and the one-axis fixed gear 8 on the first shaft 1 meshes with the intermediate shaft double gear 7, One-shaft double gear 6 meshes with countershaft ...

Embodiment 2

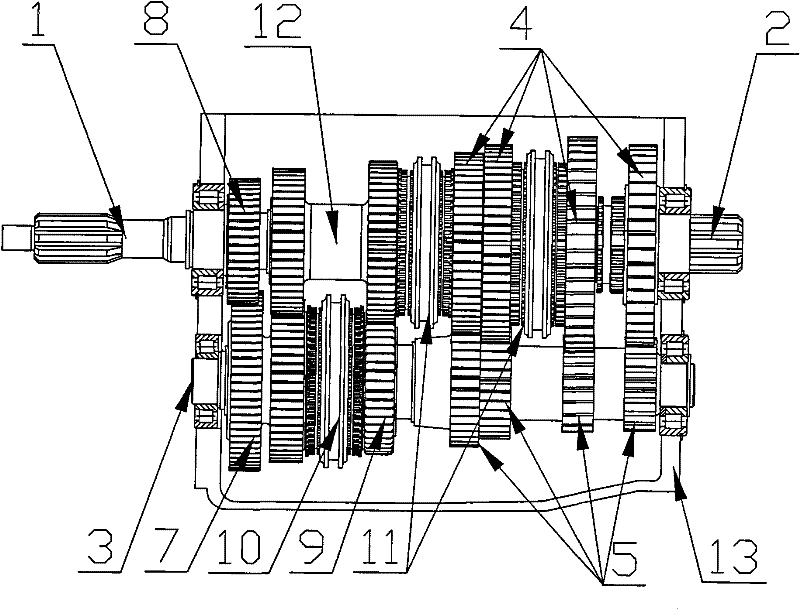

[0011] Embodiment 2 A three-shaft single-box multi-speed automobile transmission equipped with dual gears on two shafts

[0012] Such as figure 2 Shown, a kind of three-shaft type single case multi-speed automobile transmission is characterized in that: comprise main case 13, first shaft 1, two shafts 2 and intermediate shaft 3, be single case three shaft type (not including reverse gear shaft), Two-axis idler gear 4 and synchronizer 11 are installed on two-axis 2, and intermediate shaft fixed gear 5 and intermediate shaft idler gear 9 are installed on intermediate shaft 3, and the two-axis idler gear 4 and intermediate shaft fixed gear 5 are meshed with each other for transmission Torque, one shaft 1 is equipped with a fixed gear 8, the second shaft 2 is equipped with a two-axis double gear 12, the intermediate shaft 3 is equipped with an intermediate shaft double gear 7, the first shaft fixed gear 8 and the intermediate shaft double gear 7 Engagement, intermediate shaft do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com