Inner contact supporting and biasing insulator

A technology of insulators and contacts, which is used in the manufacture and connection of parts of connecting devices, contact boxes/bases, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

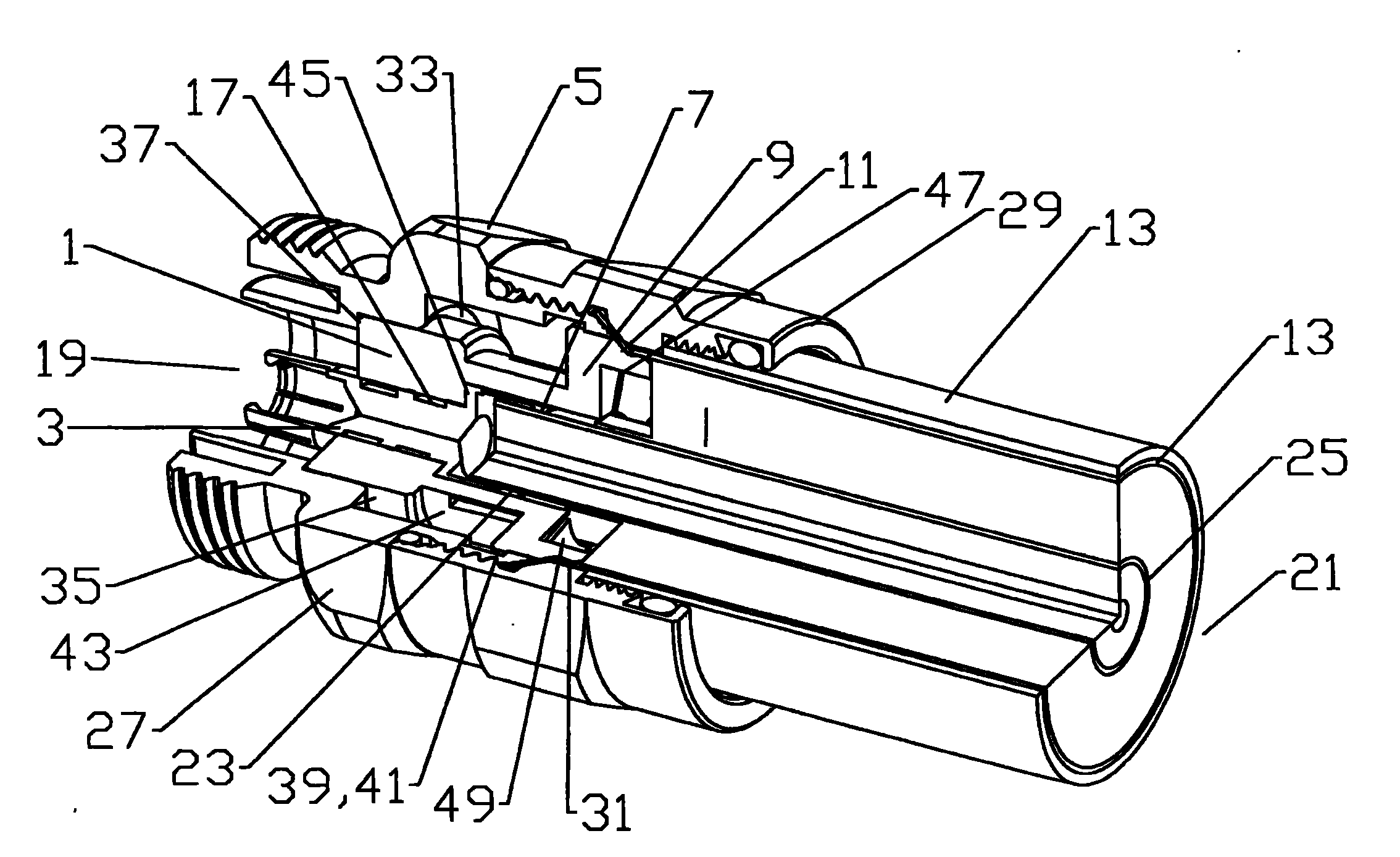

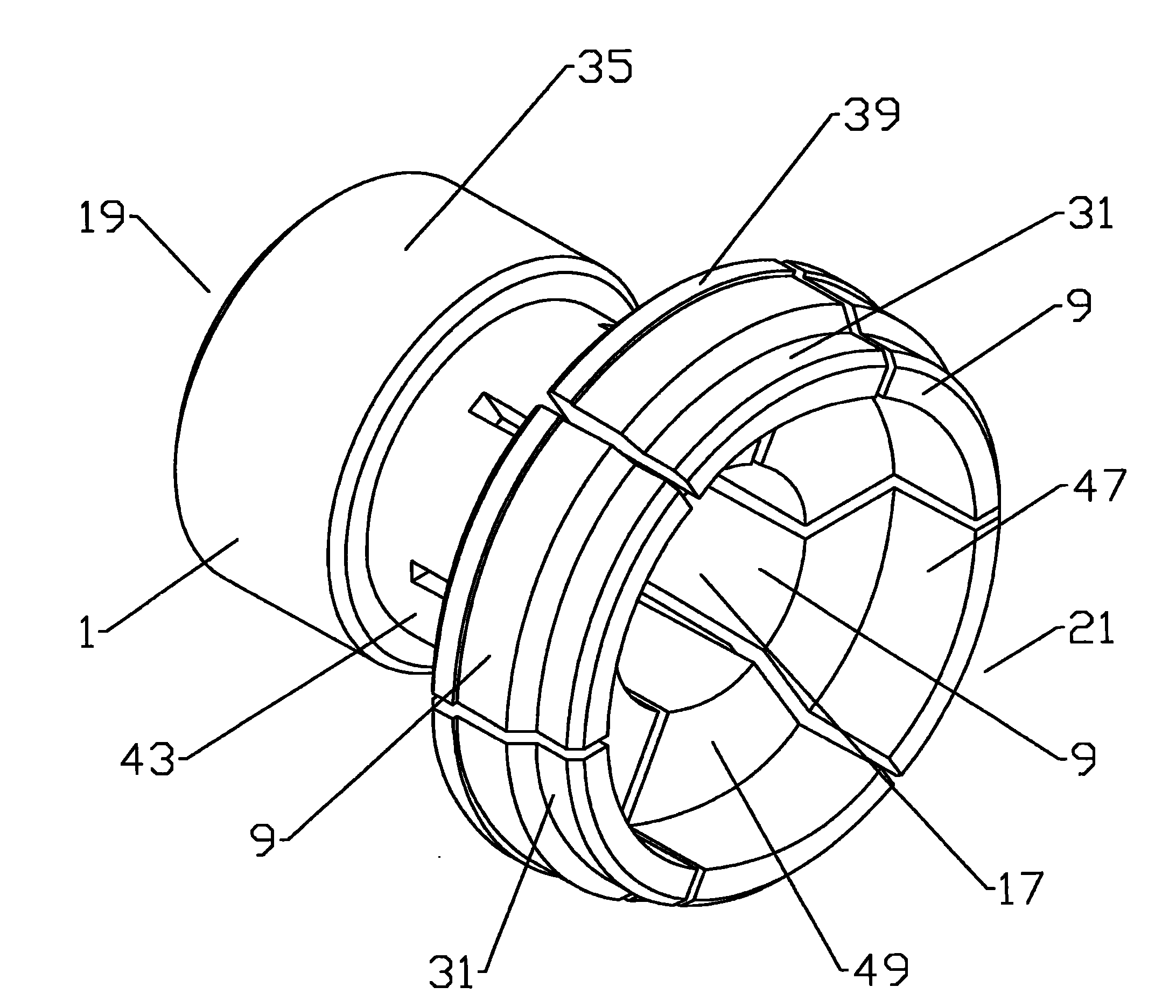

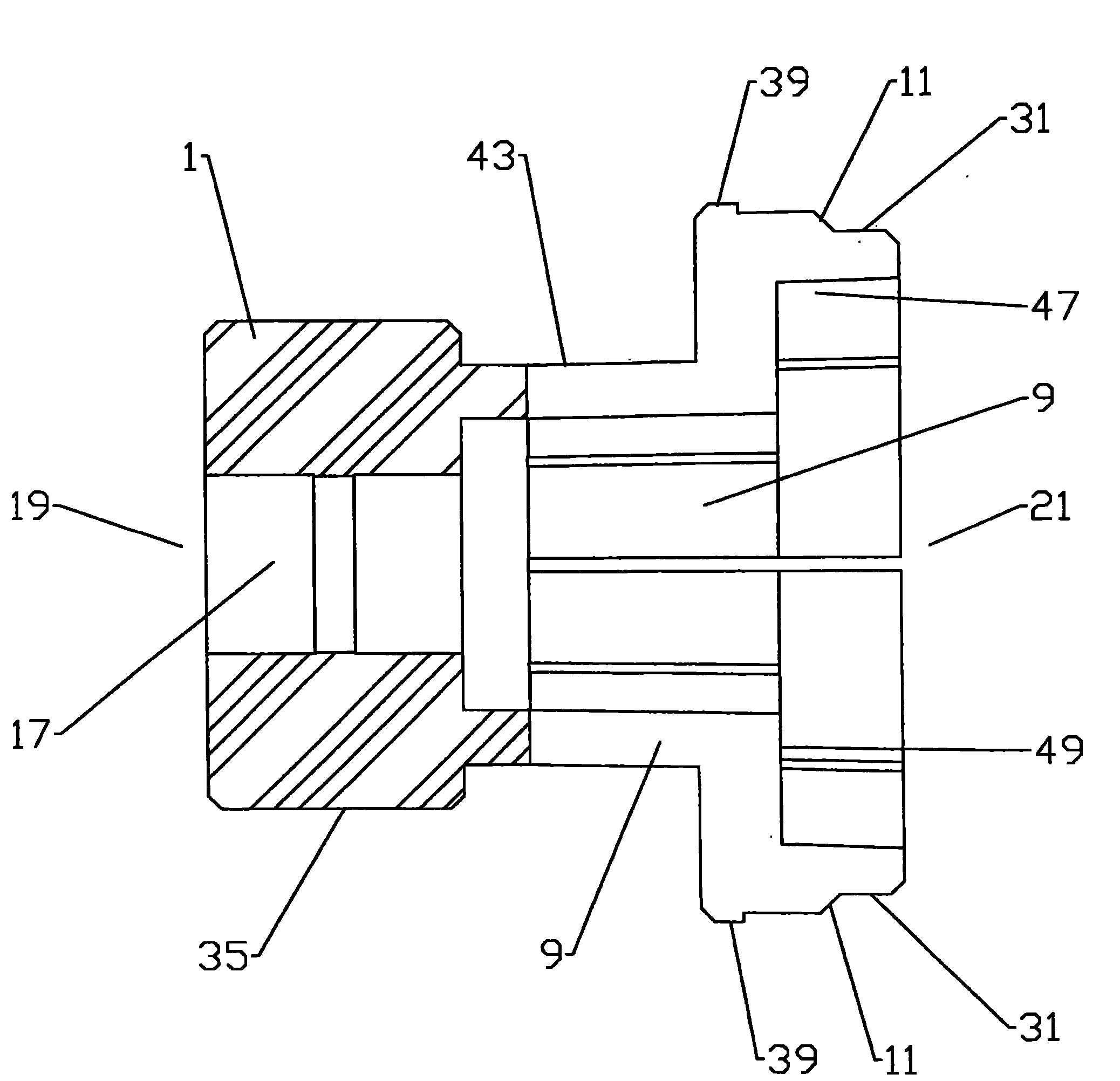

[0043] Such as figure 1 As shown, the exemplary insulator 1 according to the present invention provides a one-piece insulator 1 part which both supports the inner contact 3 in the connector 5 and provides a deflectable insulator spring claw 9 with an inclined surface 11 towards the inner contact 3. Due to the progressive inward bias of the spring bracket 7, the inclined surface 11 comes into contact with the outer conductor 13 during the connector 5 / coaxial cable 15 interconnection.

[0044] best as figure 2 with 3 As shown, the insulator 1 may be manufactured as a unitary body of dielectric material, such as a polymer, with an internal contact hole 17 extending between the connector end 19 and the cable end 21 , for example by injection molding and / or machining. Those skilled in the art will appreciate that cable end 21 and connector end 19 are descriptors used here to make the longitudinal positioning and contact interrelationships between the various components of the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com