Variable-capacitance element, method for adjusting variable-capacitance element, variable-capacitance device and electronic apparatus

A technology of variable capacitance and capacitive elements, which is applied in the direction of variable voltage capacitors, capacitors, circuits, etc., can solve problems such as not suitable for high-power applications, and achieve the effect of correcting deviation or tuning frequency offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] The variable capacitance element according to the present invention is a writable variable capacitance element whose capacitance can be rewritten, and is also a nonvolatile variable capacitance element whose capacitance, once written, can be maintained when no voltage is applied. As will be described later, when a variable capacitance device including a variable capacitance element according to the present invention is built into electronic equipment, the capacitance of the variable capacitance element can also be corrected after completion of the electronic equipment.

[0081] Embodiments of the present invention will be described below with reference to the accompanying drawings.

[0082] [Method of adjusting variable capacitance element]

[0083] First, a method of adjusting a variable capacitance element according to the present invention will be described.

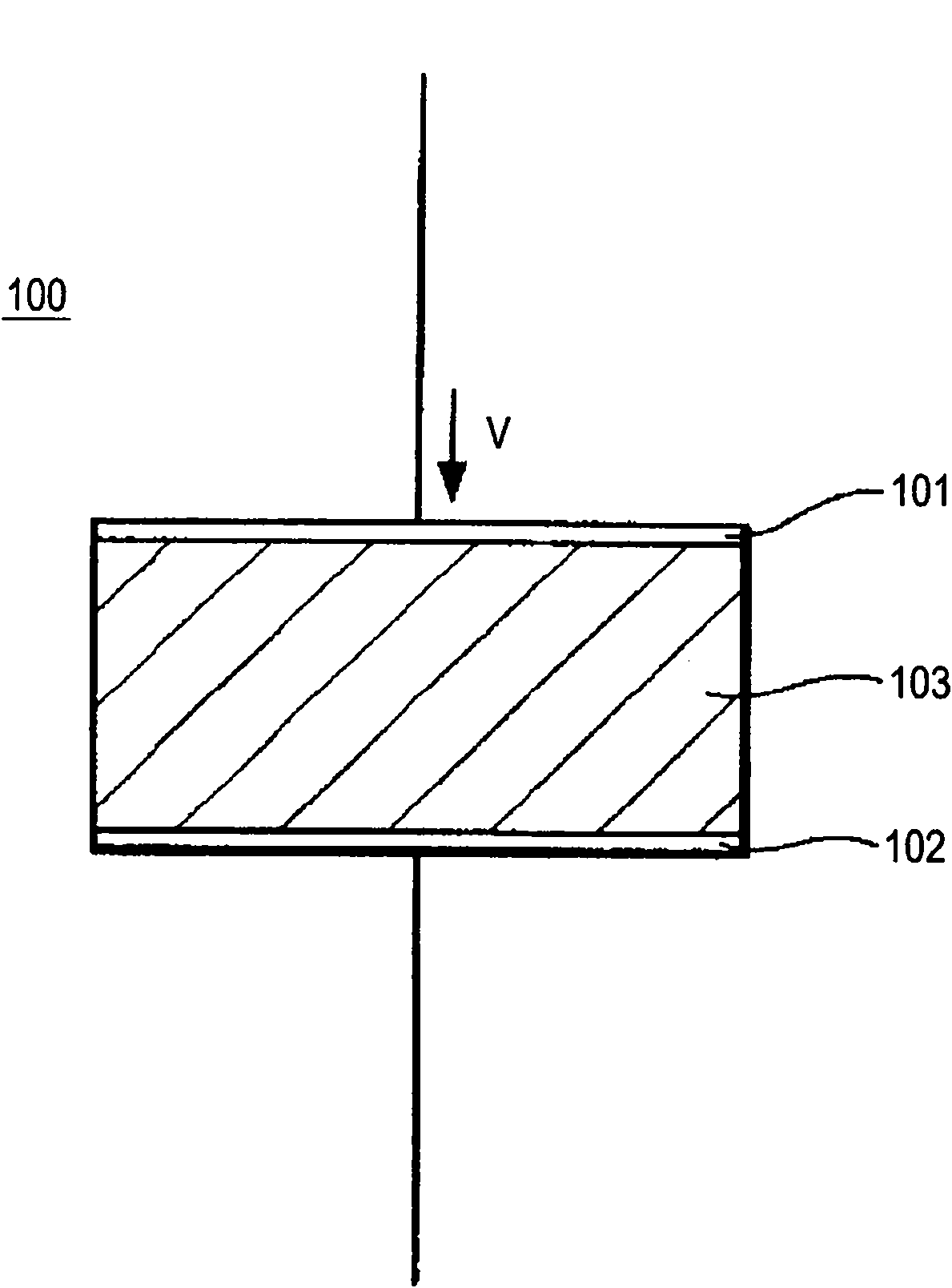

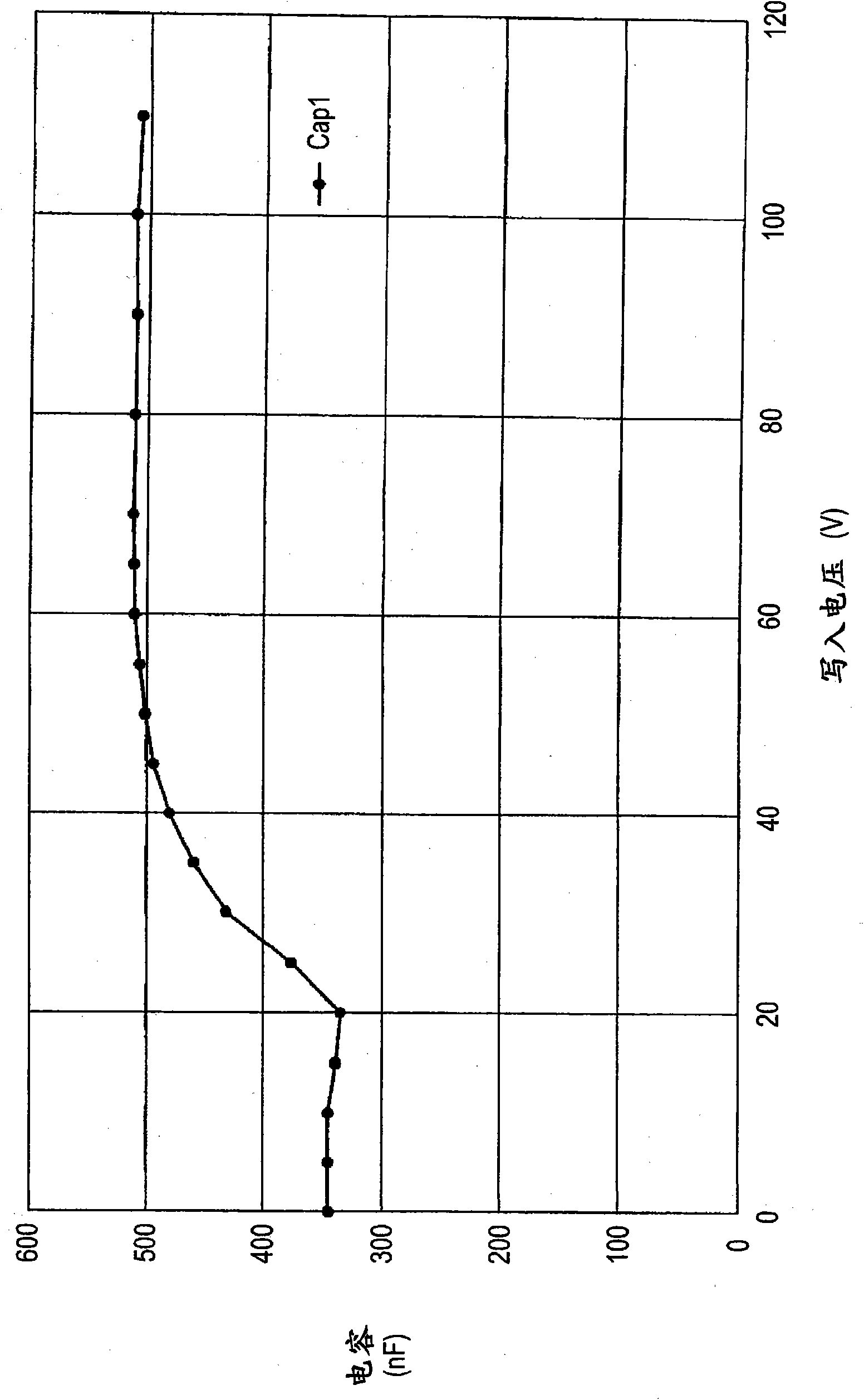

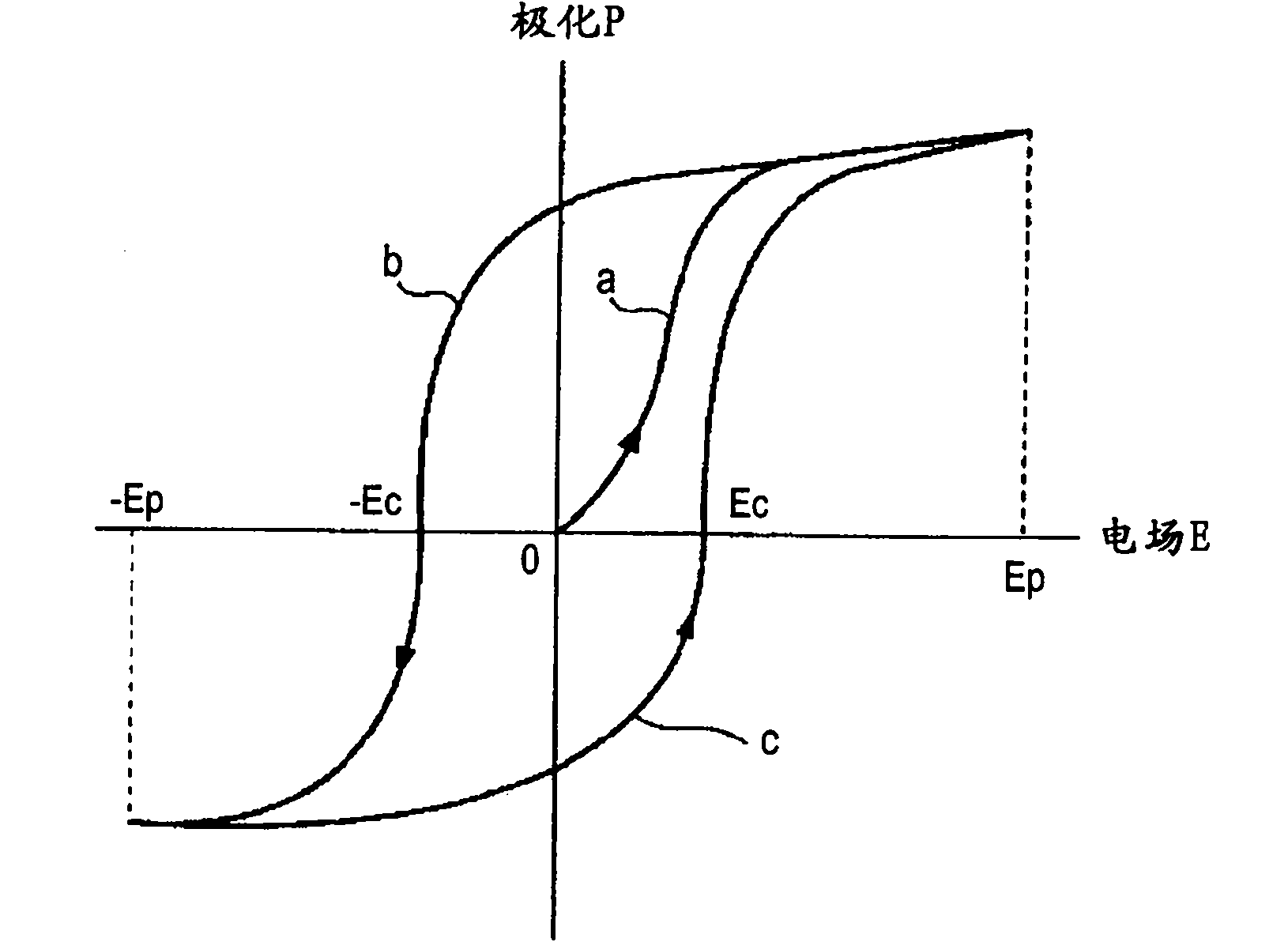

[0084] figure 1 A schematic configuration of a variable capacitive element for use in one embodiment of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com