Vibration isolation device for track traffic

A rail transit and vibration isolation technology, which is applied in the direction of tracks, roads, buildings, etc., can solve the problems that the vibration isolation device cannot be adjusted steplessly, and the height adjustment is limited, so as to achieve rapid consumption of residual vibration and good vibration isolation effect , The effect of easy installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

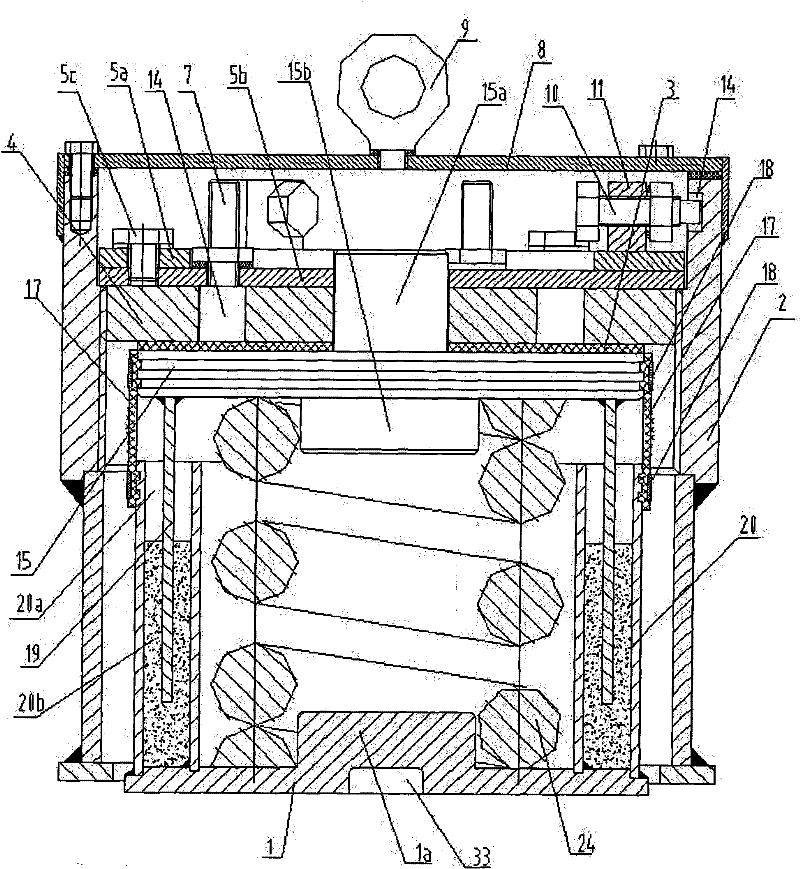

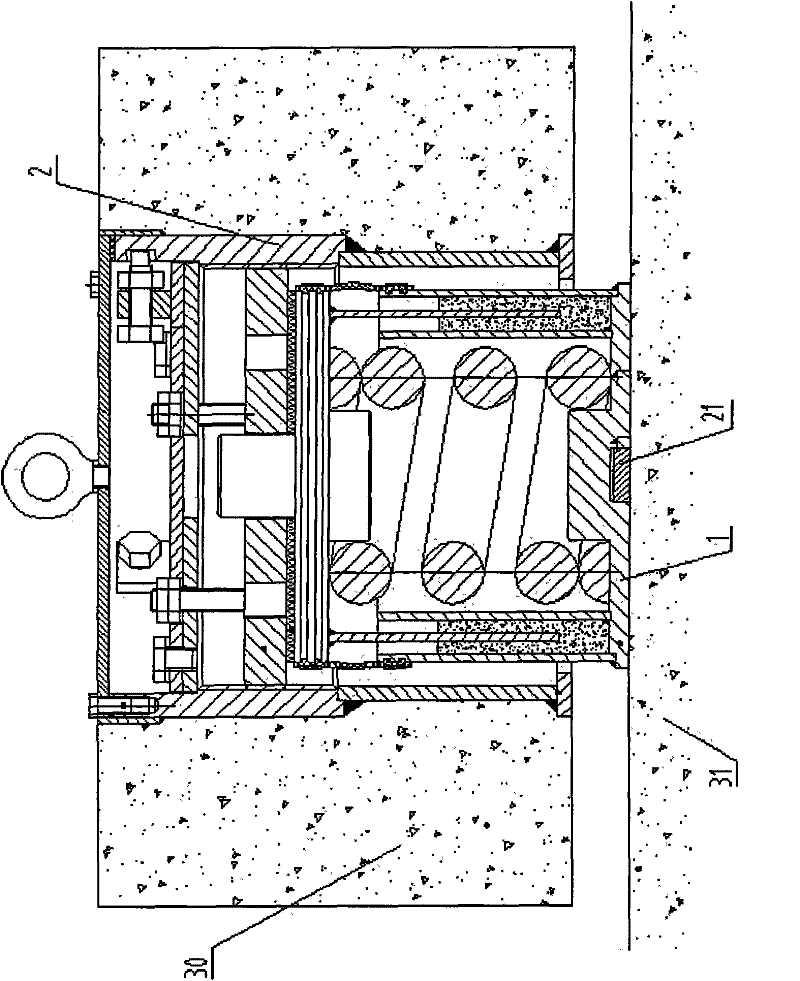

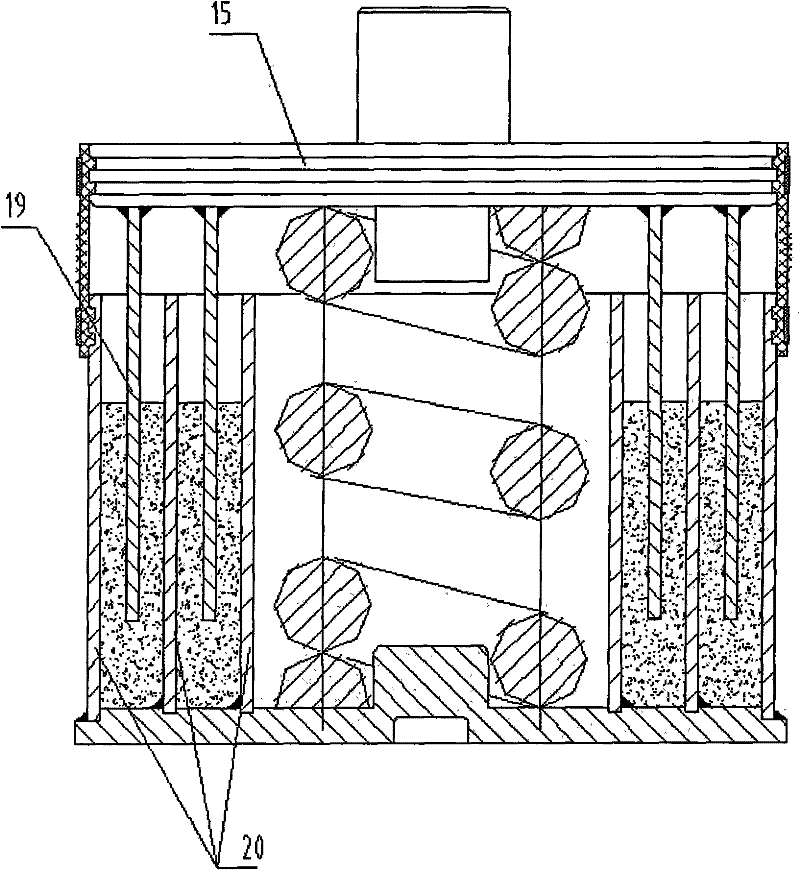

[0027] Example: such as figure 1 , 2 , as shown in 5:

[0028] A vibration isolation device for rail transit, the vibration isolation device includes a vibration isolation inner cylinder, a vibration isolation outer cylinder 2 and a height adjustment seat 4, the vibration isolation inner cylinder is sleeved in the vibration isolation outer cylinder 2, the vibration isolation outer cylinder 2 The height-adjusting seat 4 is installed in the vibration-isolation outer cylinder 2 and is threadedly connected with it. The vibration-isolation inner cylinder includes a base 1, an annular damping cylinder 20, an upper support plate 15 and a shear cylinder 19. The annular damping cylinder 20 Installed on the base 1, the annular damping cylinder 20 has an annular groove 20a, the annular groove 20a is filled with a damping liquid 20b, the upper end of the shearing cylinder 19 is fixed on the upper support plate 15, and the lower end is inserted into the annular In the damping liquid 20b ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com