Method of applying an undercoat in an ink jet recording apparatus

A technology of inkjet recording and base agent, applied in printing devices, printing, etc., can solve problems such as infiltration, and achieve the effects of preventing oozing, high-quality inkjet recording, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

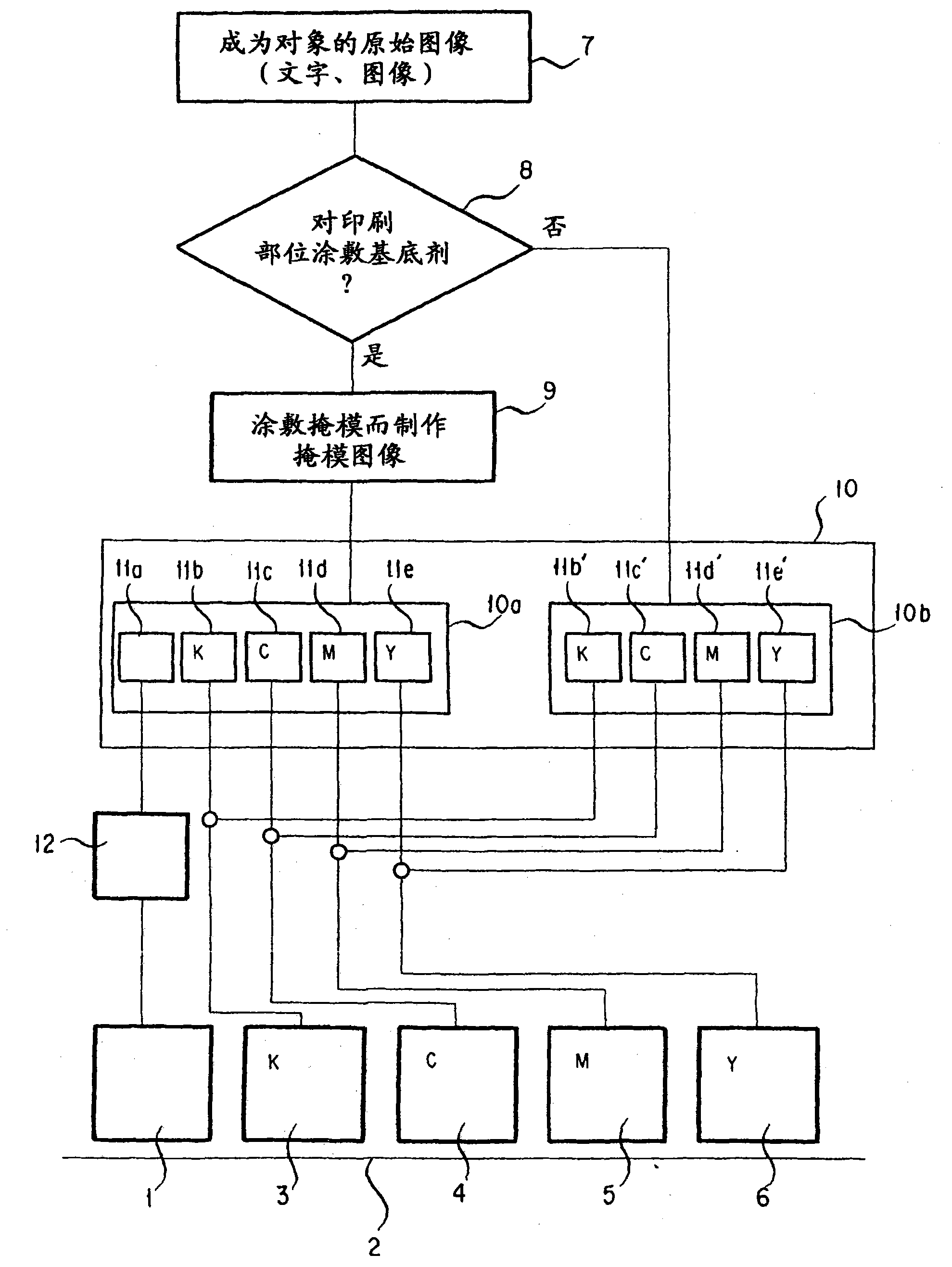

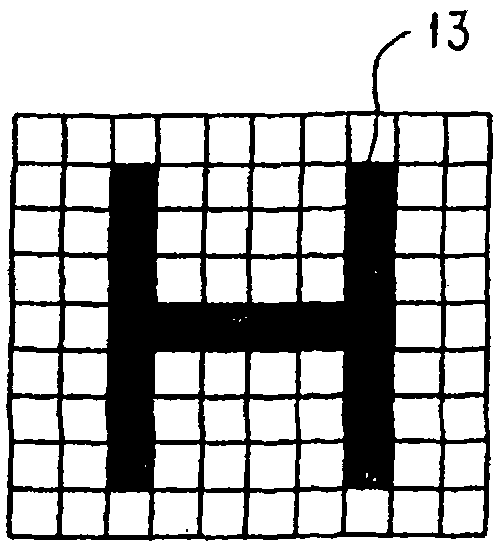

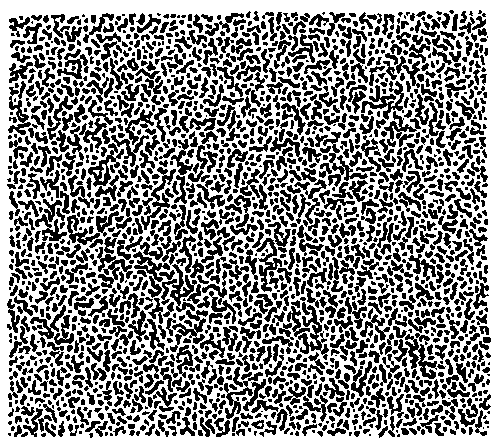

[0022] In the method of the present invention, the application data of the base agent is prepared in advance according to the program processing determined by the software mode according to the information recording data, and through the application data in the recording area of the information, along with the advancement of the recorded medium, first pass The substrate head applies the substrate agent, and then prints the substrate-applied portions sequentially with the printing heads of the respective colors. At this time, the area where the base agent is applied is slightly larger than the area where printing is performed by the print head, and printing is performed inside the area where the base agent is applied.

[0023] According to this method, information recording and primer coating can be directly performed on the recording medium through each printing head according to the printing data, so the amount of communication data used for these recording and coating can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com