Improved type needle cylinder illustration

An improved, needle-cylinder technology, used in knitting, weft knitting, textiles and papermaking, etc., can solve problems such as shortening the service life of running parts, and achieve the effects of increasing service life, reducing running friction and reducing heat generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and embodiment the structure of the present invention is described in detail:

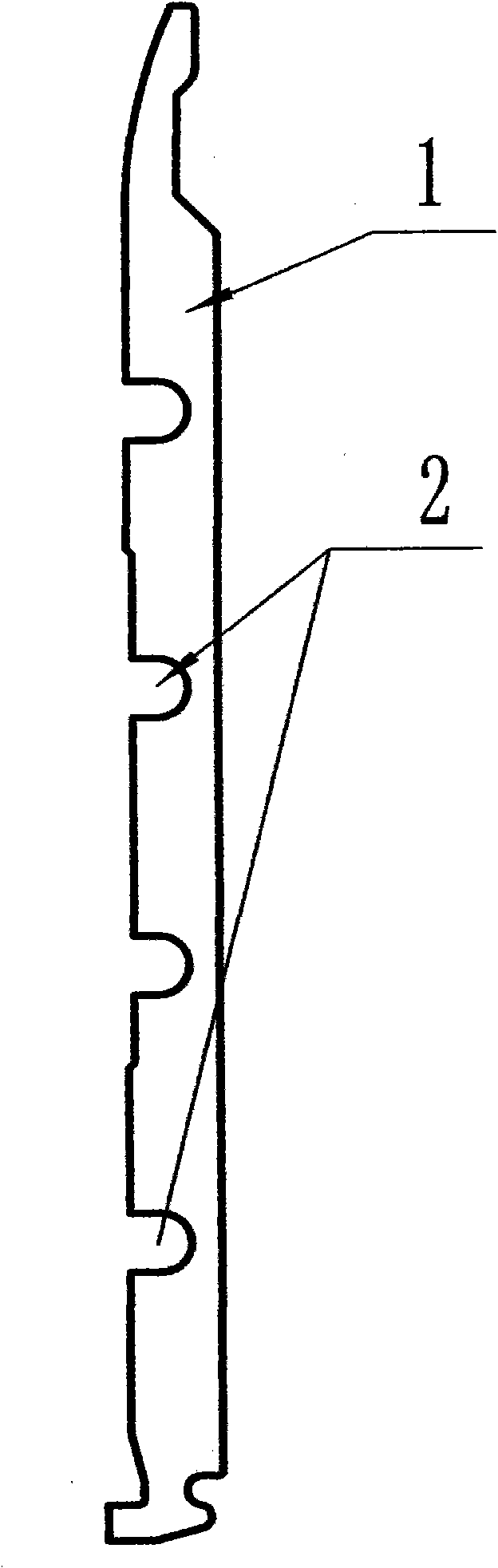

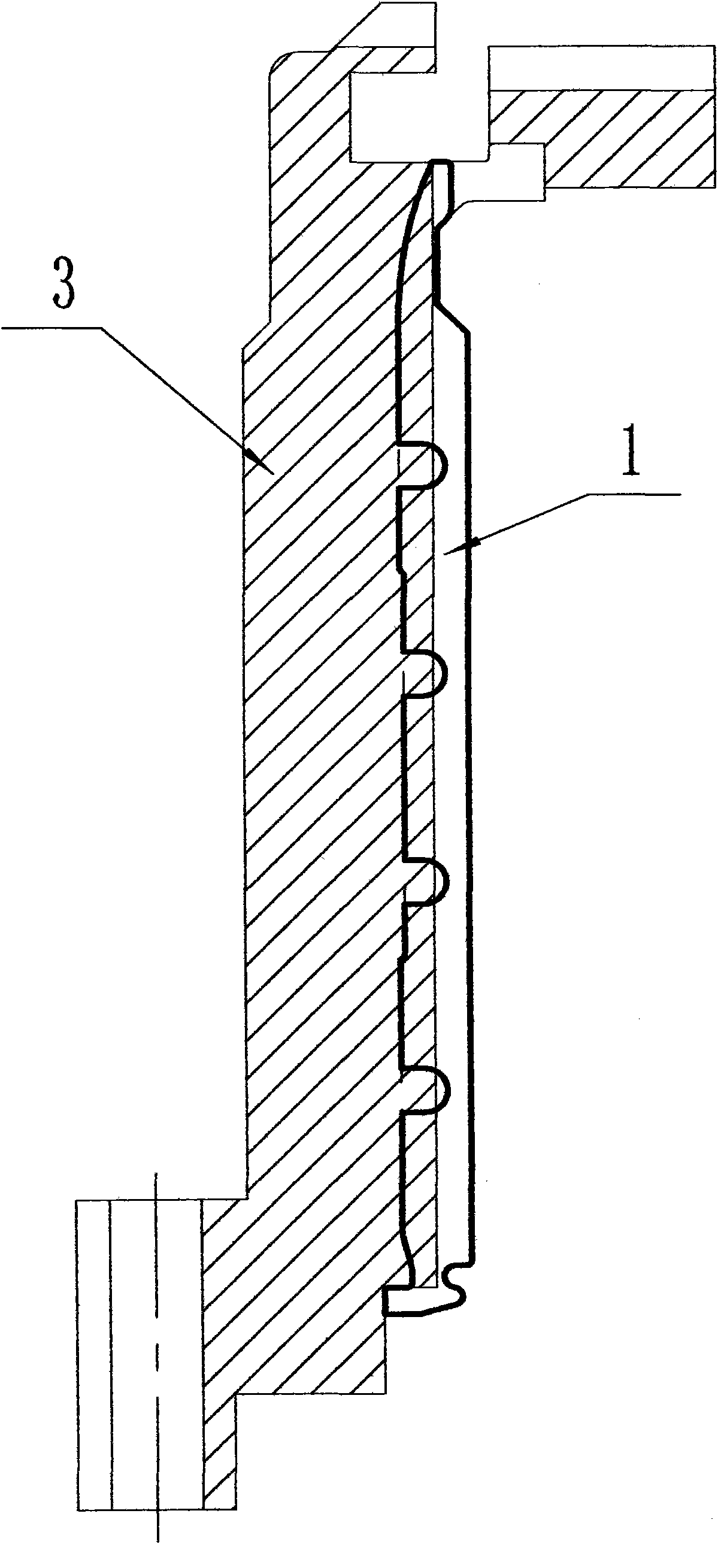

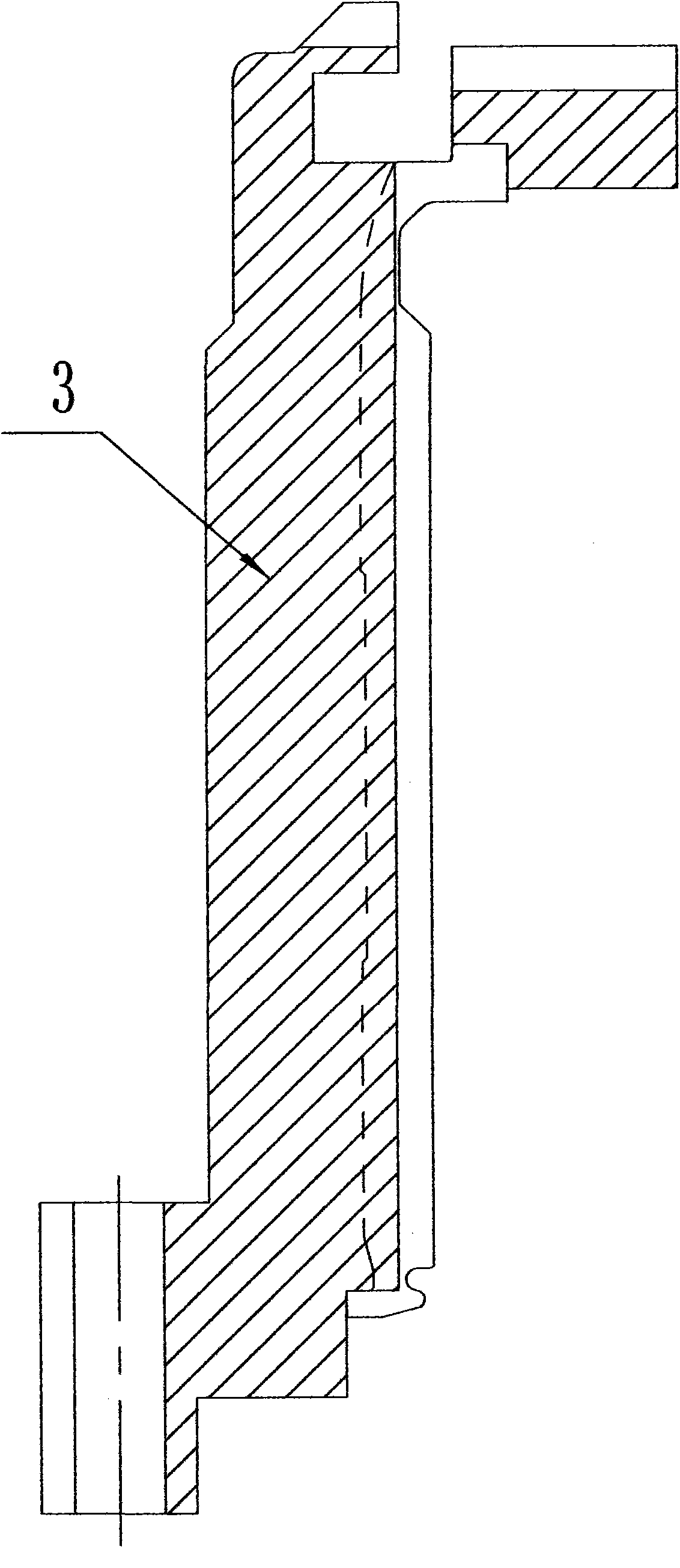

[0013] like figure 1 , Picture 1-1 , figure 2 , image 3 As shown, an improved cylinder insert of the present invention includes a cylinder insert body 1 of a circular knitting machine, and its structural feature is that there is a bottom of the cylinder insert body 1 of a large circular knitting machine. Or a plurality of notches 2, plural refers to more than 2, when the syringe body 1 is inserted into the syringe body 3, a reservoir is formed between the notch 2 at the bottom and the outer diameter of the corresponding syringe body 3. The oil in the oil hole and the oil storage hole can flow and distribute evenly inside the syringe body 3, so the oil can lubricate the running parts connected with the syringe body, such as the syringe itself, the needle insert, the knitting needle, etc. , so as to reduce the frictional resistance generate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com