Suction retaining device used in water channel field

A technology in the waterway and field, applied in water supply devices, valve devices, spray devices, etc., can solve problems such as inconvenient use, waste of water resources, lower water pressure, etc., and achieve easy assembly, high action accuracy, and strong plugging performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

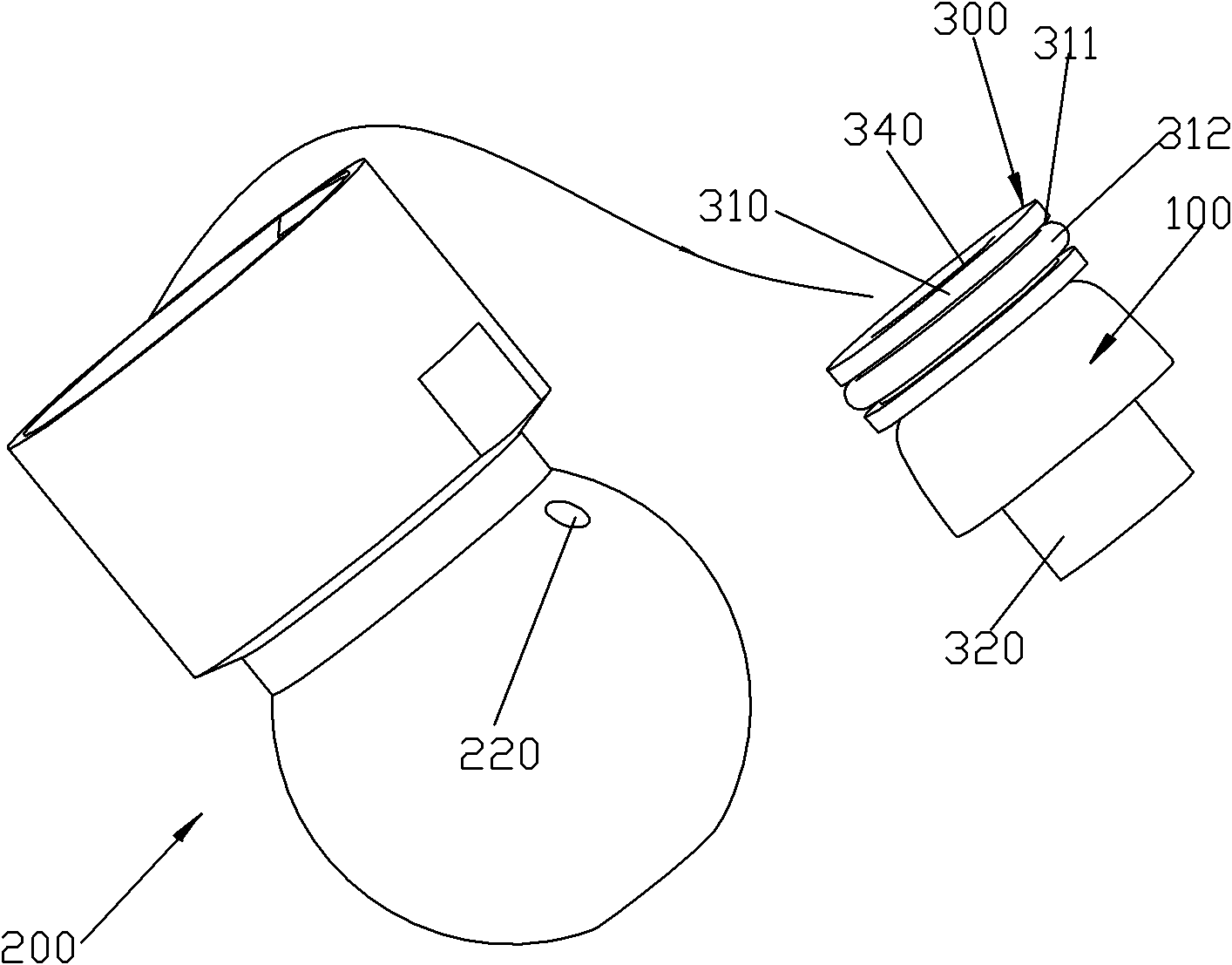

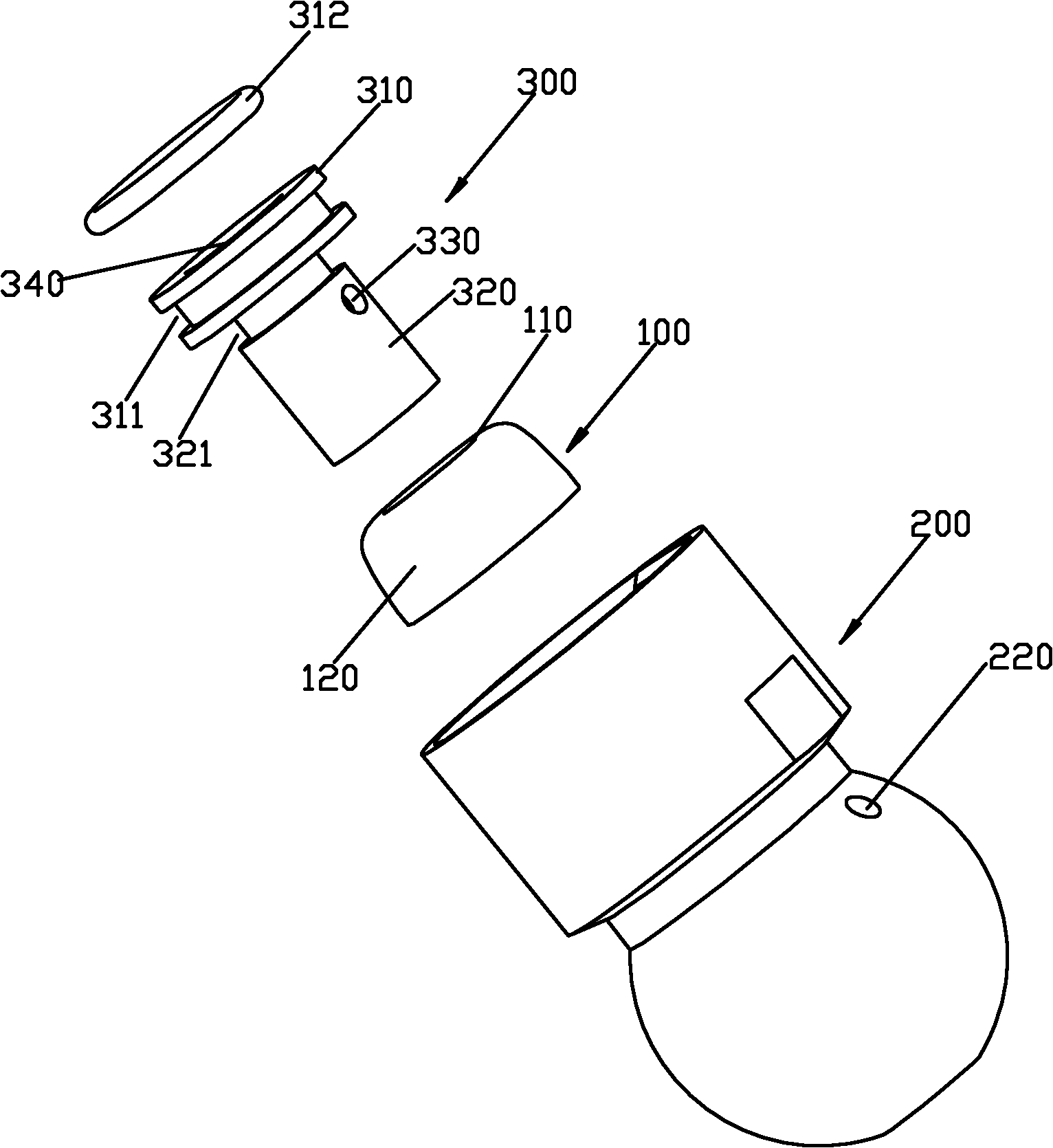

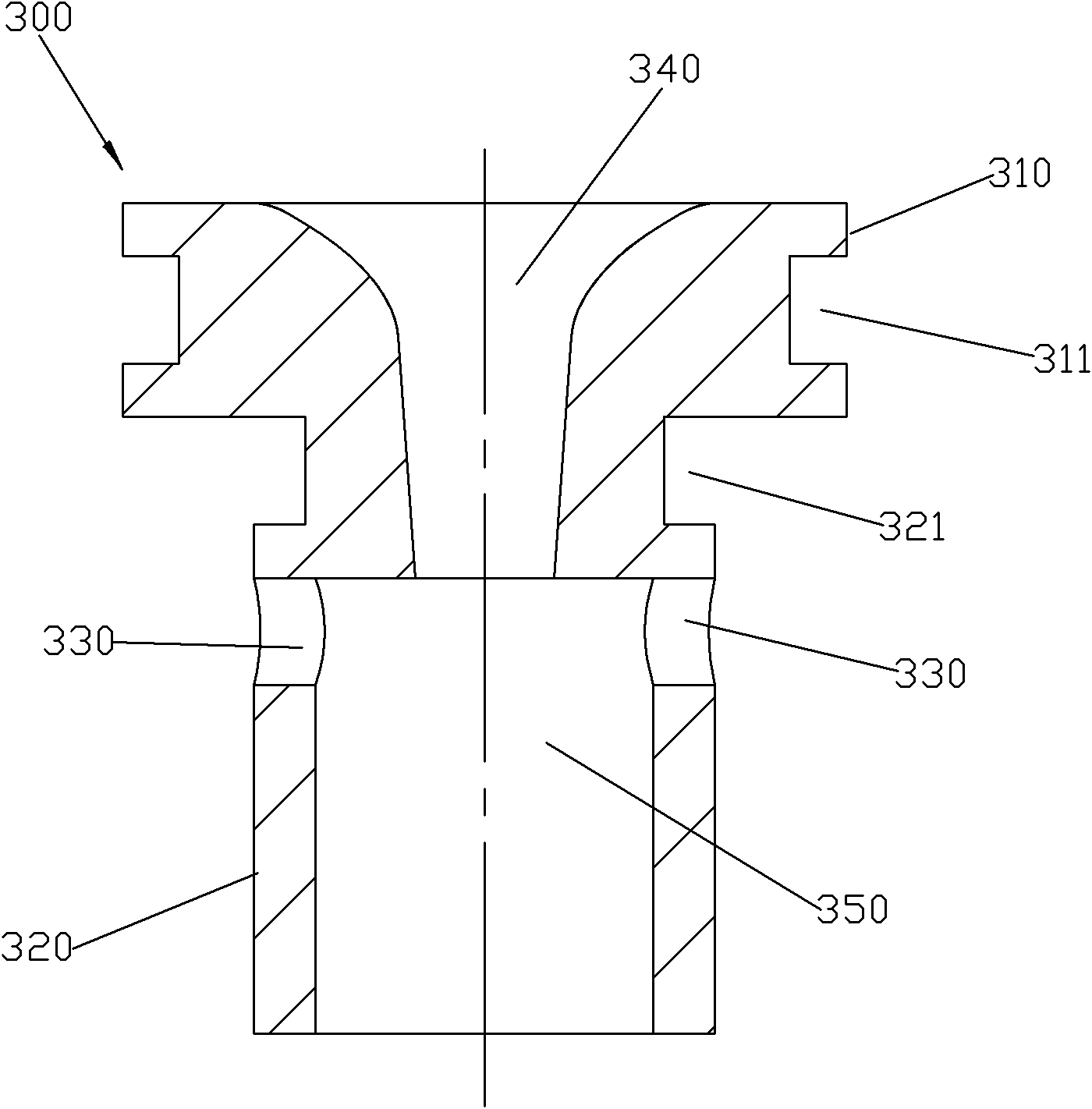

[0042] Please check Figure 1 to Figure 6 , an anti-reverse suction device used in the waterway field, which includes a main body and an elastic sealing sleeve 100 .

[0043] The main body includes a base 200 and an inner frame 300 .

[0044] A stepped hole and two first through holes 220 are defined in the support 200 .

[0045] The stepped hole has a large hole 211 and a small hole 212, and the large hole 211 and the small hole 212 are arranged up and down. In this embodiment, the stepped holes are rotary holes. The upper port of the large hole 211 is provided with an internal thread.

[0046] The two first through holes 220 are arranged symmetrically. The first through hole 220 runs through the inside and outside of the large hole 211, the axis of the first through hole 220 is inclined, the outer port of the first through hole 220 is located on the outer side of the support 200, the first through hole 220 The inner port of is located on the inner side of the large hole...

Embodiment 2

[0055] Please check Figure 7 to Figure 10 The difference between this preferred embodiment 2 and the preferred embodiment 1 lies in that: the outer turning surface of the upper end of the support 200 is provided with external threads; the axis of the first through hole 220 is arranged horizontally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com