Shielding and temporary plugging gelling agent for drilling fluid and production method and use method thereof

A drilling fluid and gelling agent technology, applied in chemical instruments and methods, earthwork drilling, flushing wells, etc., can solve the problems of interfering with geological logging work, economic losses, damage to oil and gas layers, etc., and achieve the effect of apparent viscosity Low, low viscosity effect, strong blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

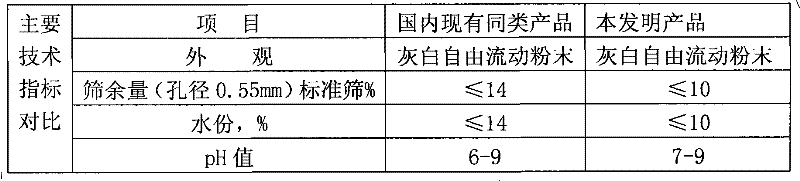

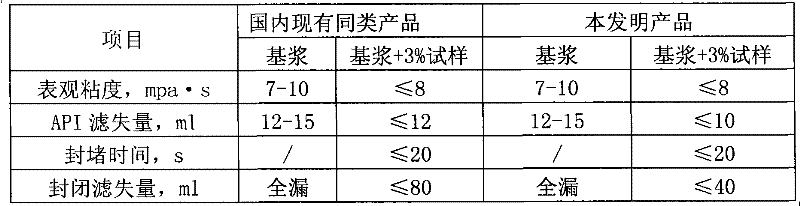

[0018] Example 1, the drilling fluid shielding temporary plugging gelling agent is composed of: 66.5% expanded short plant fibers, 20% strong plugging powder, 10% fluid loss reducer or flow pattern improver, 3% vegetable glue Coagulant, 0.5% calcifying agent; the results of inspection by Xinjiang Uygur Autonomous Region Petroleum Drilling Auxiliary Products Quality Supervision and Inspection Station are as follows:

[0019] project

Embodiment 2

[0020] Example 2, the drilling fluid shielding temporary plugging gelling agent is composed of: 55% expanded short plant fiber, 24% strong plugging powder, 10% fluid loss reducer or flow pattern improver, 10% vegetable glue Coagulant, 1% calcifying agent; the results of inspection by Xinjiang Uygur Autonomous Region Petroleum Drilling Auxiliary Products Quality Supervision and Testing Station are as follows:

[0021] project

Embodiment 3

[0022] Example 3, the drilling fluid shielding temporary plugging gelling agent is composed of 50% expanded short plant fiber, 28% strong plugging powder, 11% fluid loss reducer or flow pattern improver, and 9% plant gelling agent by weight percentage calcification agent, 2% calcification agent; the inspection results of Xinjiang Uygur Autonomous Region Petroleum Drilling Auxiliary Product Quality Supervision and Inspection Station are as follows:

[0023] project

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com