Silk-screen product plugging method and tool

A technology for screen-printing plug holes and products, which is applied to the formation of electrical connection of printing components, etc., can solve the problems of plugging holes and can not guarantee product reliability, etc., and achieves the effect of avoiding plugging foaming and improving plugging ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described below in conjunction with the drawings.

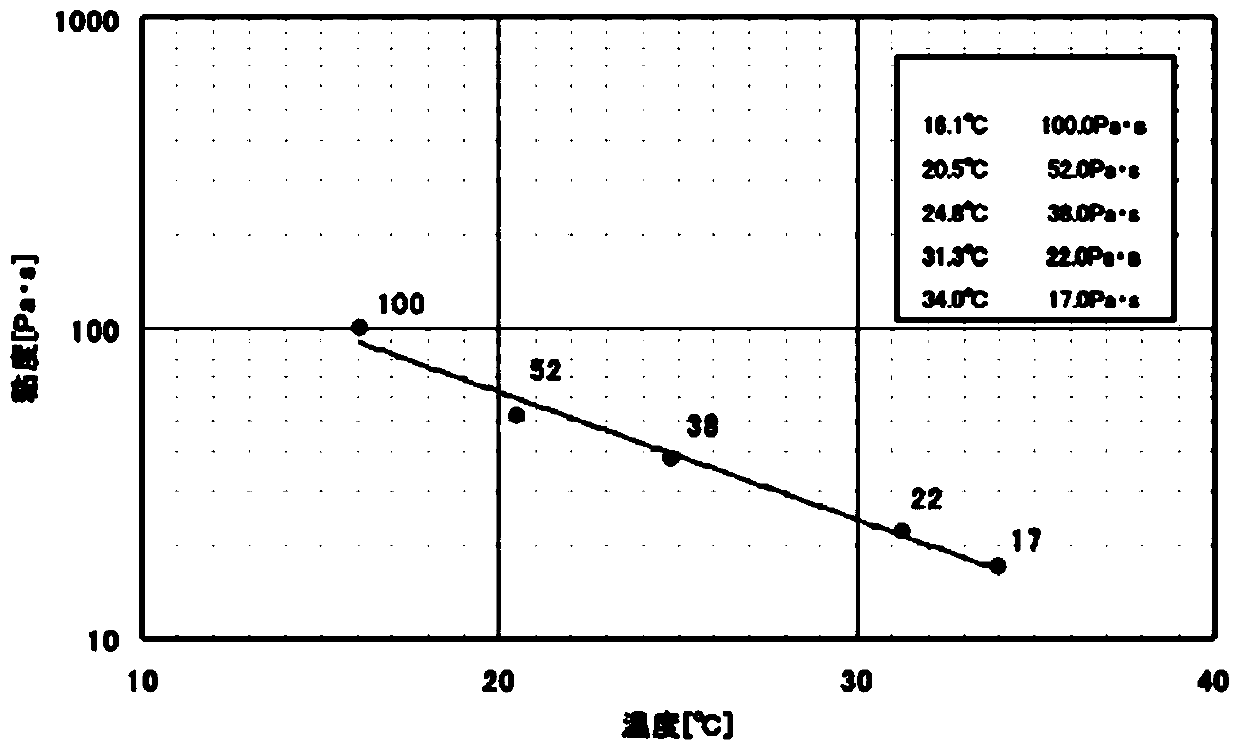

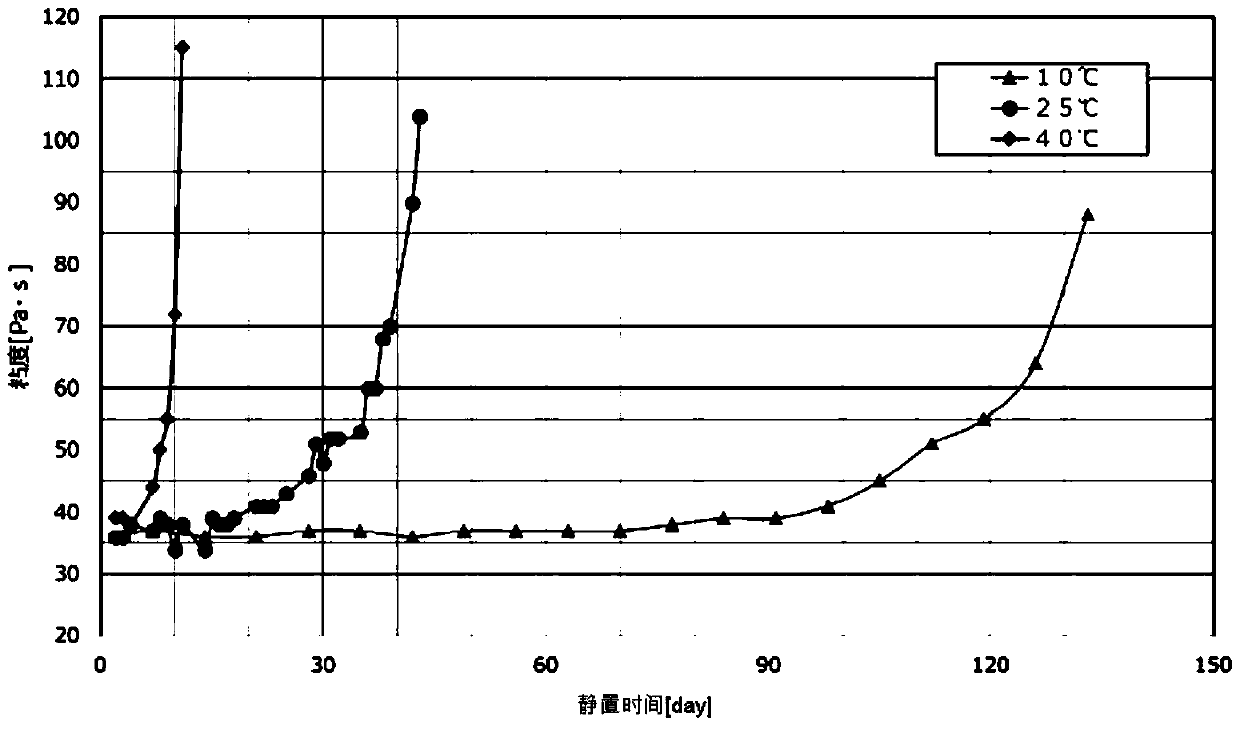

[0020] The basic idea of the present invention is that the present invention proposes a method of plugging holes by heating the ink to reduce the viscosity. In this method, the ink is slightly warmed up, and a low-power heater is installed on the ink return knife of the screen printing machine to maintain the ink at a considerable temperature. If the silk screen plugging is carried out under certain conditions, the viscosity of the ink will decrease after heating up, and it will be easier to penetrate the hole wall, which can greatly improve the plugging ability and avoid the occurrence of plugging bubbles.

[0021] A method for plugging holes of silk screen products, which includes a heating step and a heat preservation step.

[0022] In the pre-heating step, the ink is heated up to reduce its viscosity by half compared to that before heating. The ink heating temperature is between 33 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com