Self-closed water-saving device, method and toilet stool

一种节水装置、自闭式的技术,应用在供水装置、阀装置、阀的操作/释放装置等方向,能够解决水压力低、水压要求较高、大响声等问题,达到提高速度、冲洗节水、冲洗有劲更的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

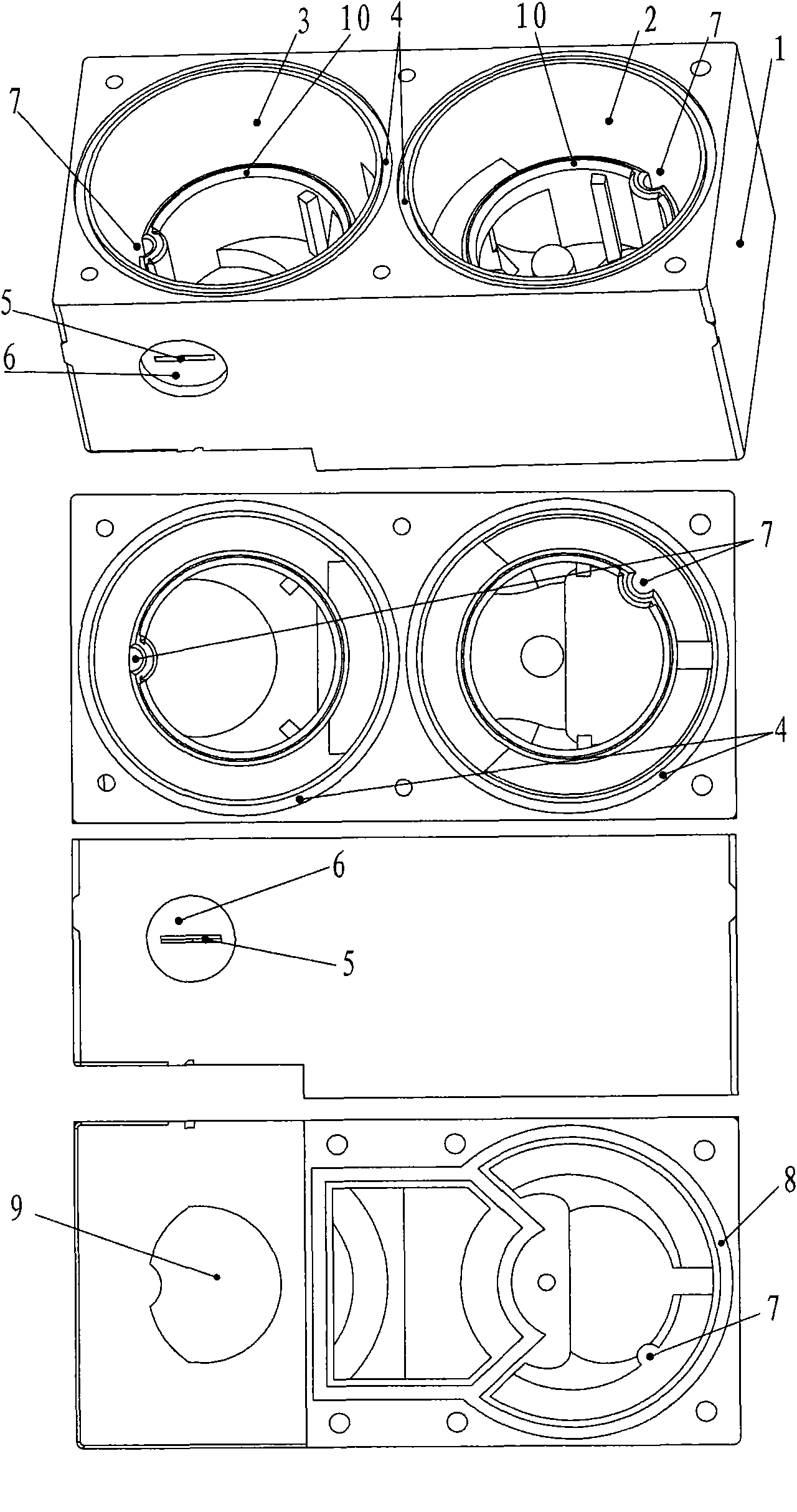

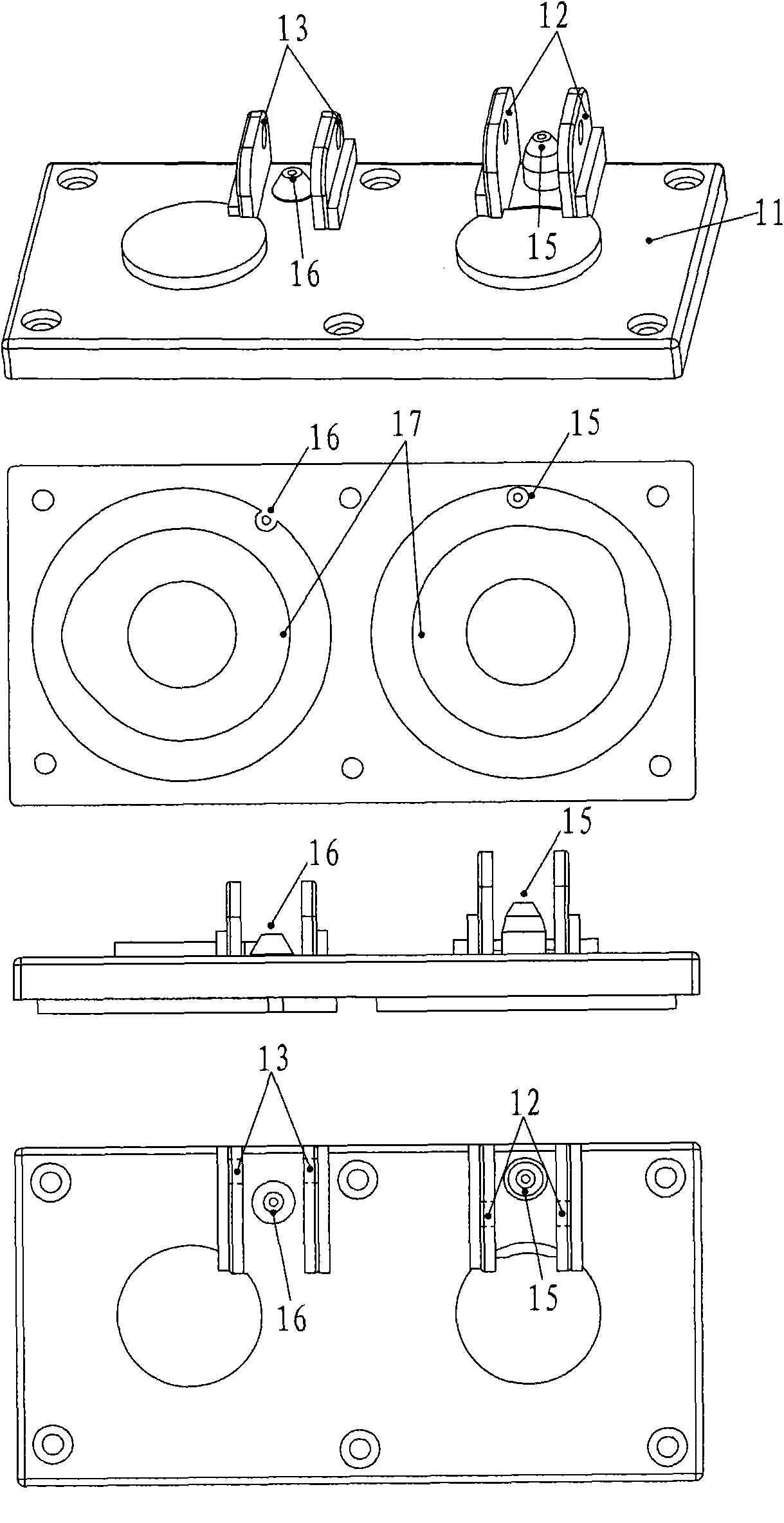

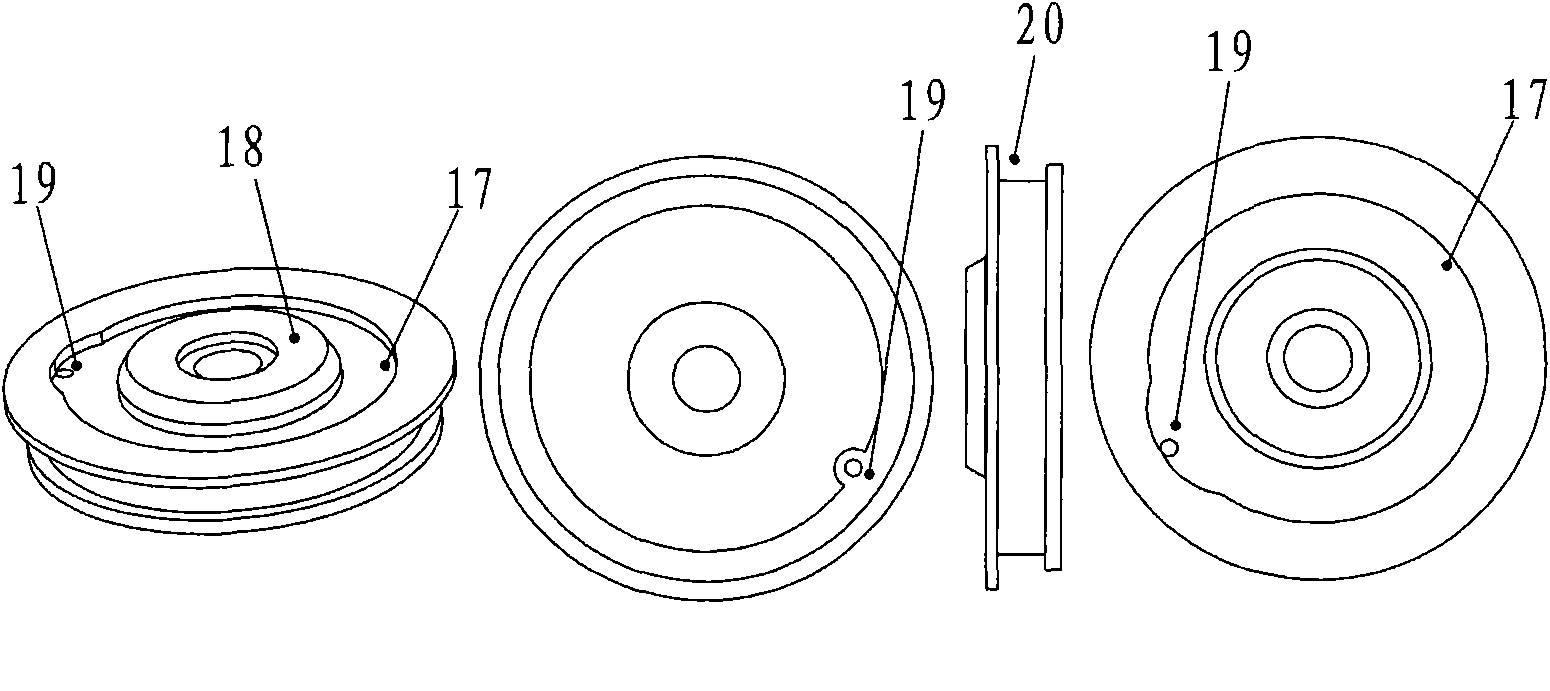

[0076] In order to unify the technical terms, the float control valve is defined as "including the valve body, valve core, valve cover, buoy and buoy tank. The mouth is connected, the valve core is movably arranged in the valve body, the valve core divides the inside of the valve body into upper and lower parts, the valve core has a hole through the upper and lower parts, the valve cover is located on the top of the valve body, and covers the valve body, the valve cover There is a spring between the valve core and the valve core, and the spring presses the valve core on the valve port to block the valve port. The valve cover is provided with a hole through the inside and outside. The pressure difference is related. When there is a predetermined pressure difference between the lower part and the upper part of the valve core, the spring will contract to move the valve core and open the valve port. The connecting rod mechanism is provided with a sealing material, which selectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com