Pressure-storing and energy-saving flushing water tank

A technology for rinsing water tanks and tanks, which is applied in the field of sanitary ware, and can solve problems such as unclean rinsing, failure to be accepted by the market, failure to replenish water, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

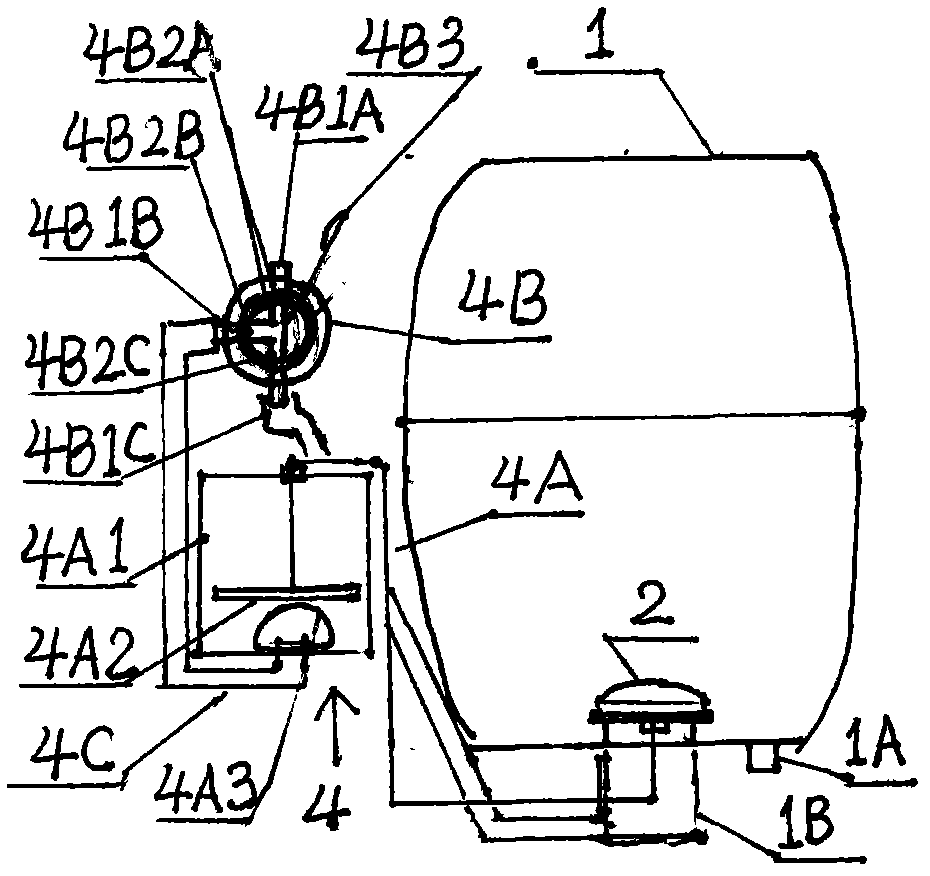

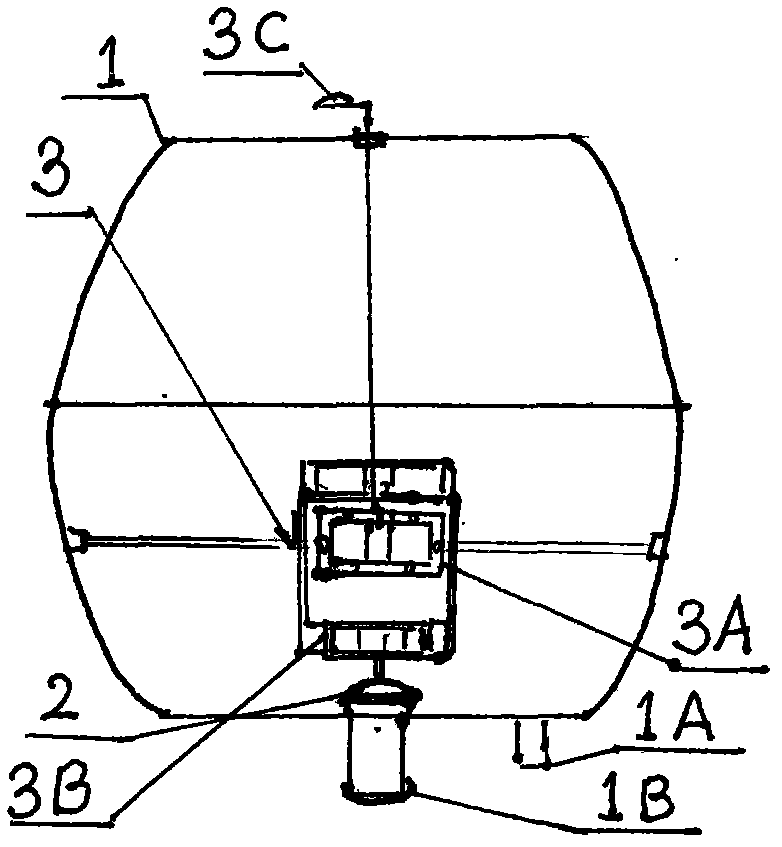

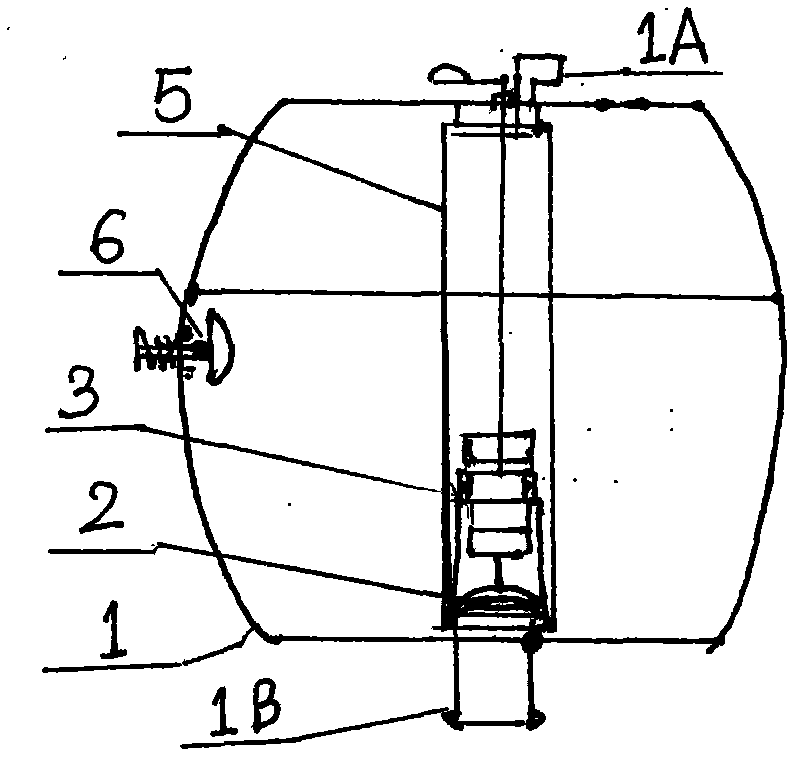

[0013] The drainage valve in the pressure storage and energy-saving flushing water tank has two kinds of start-up structures, that is, the valve flow pressure start-up device type and the valve permanent magnet start-up device type. And all of them can solve the relevant and corresponding technical problems to be solved, and have significant beneficial effects. And they can be used not only for starting the drain valve of the pressure storage energy-saving flushing water tank, but also for starting valves in other types of containers or devices or pipelines, etc., and are multi-purpose. However, the pressure storage and energy-saving flushing water tank has multiple flexible implementation modes. Below, representative embodiments and accompanying drawings are selected for further illustration. And various structural implementation modes that can be arranged optionally, do not all provide too many accompanying drawings one by one, are mainly represented by words. In addition, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com