Independent flushing flow passage system for combined water-saving toilet pan

A toilet and flushing flow technology, which is applied in the field of independent flushing flow channel systems, can solve the problems such as the lack of a mature solution for flushing flow channel systems, difficulty in obtaining flushing performance, and excellent flow channels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

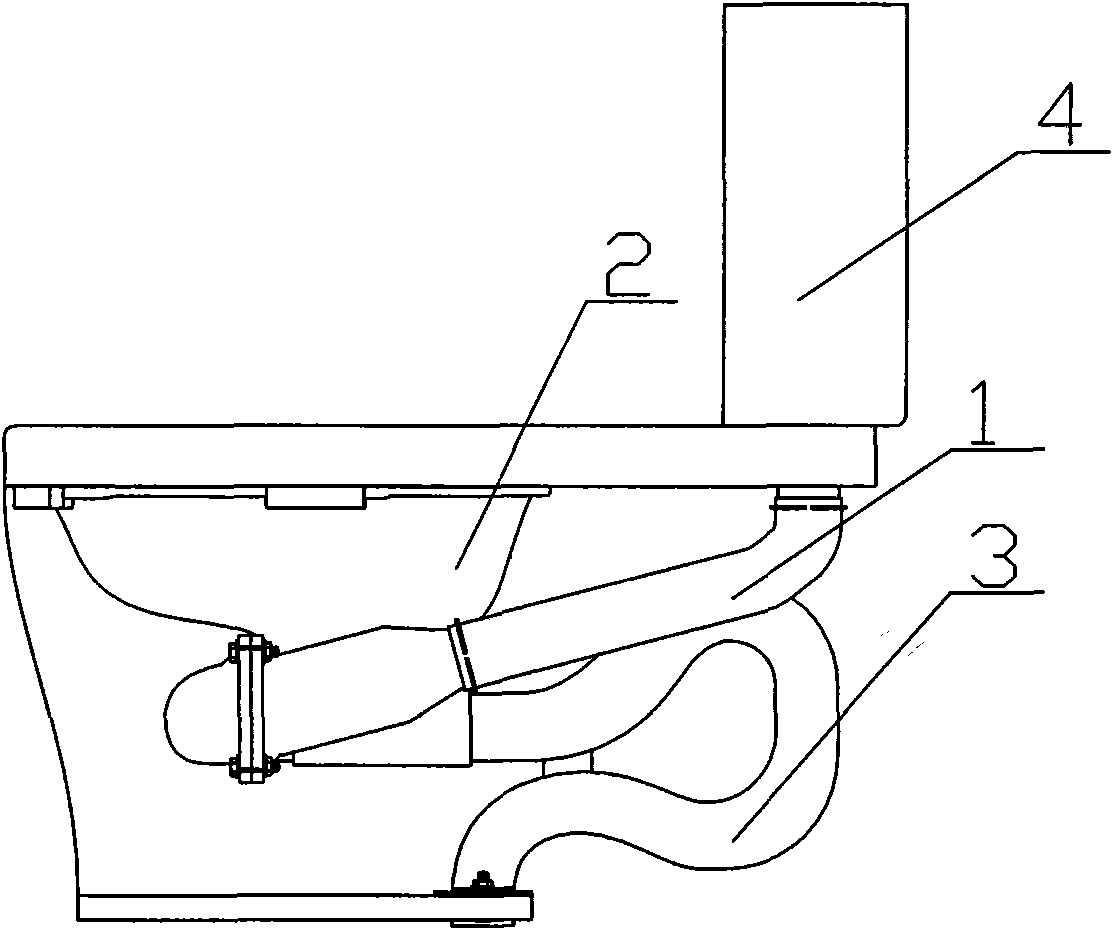

[0023] The independent flushing channel system of the combined water-saving toilet will be further described below in conjunction with the accompanying drawings and specific embodiments.

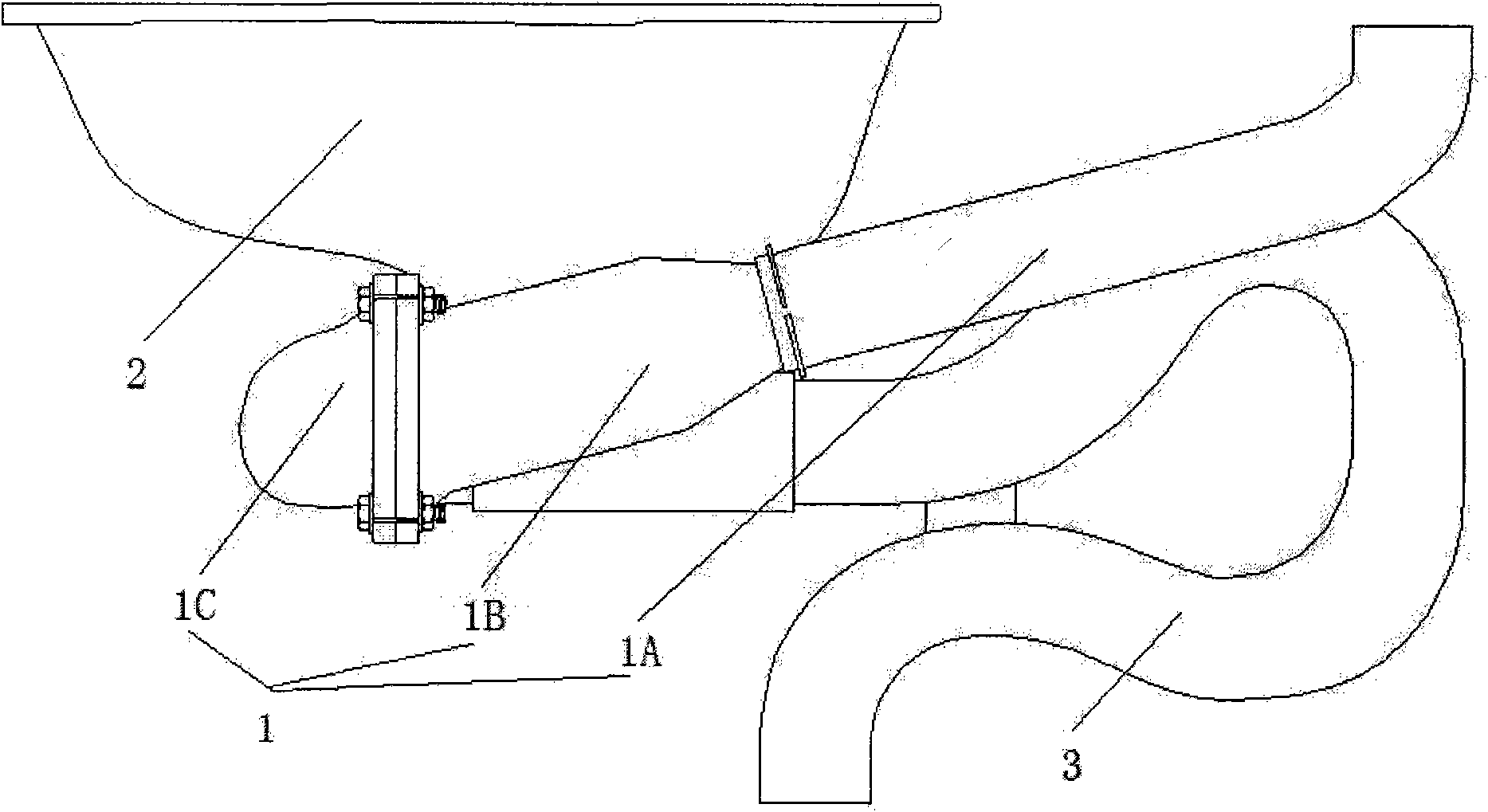

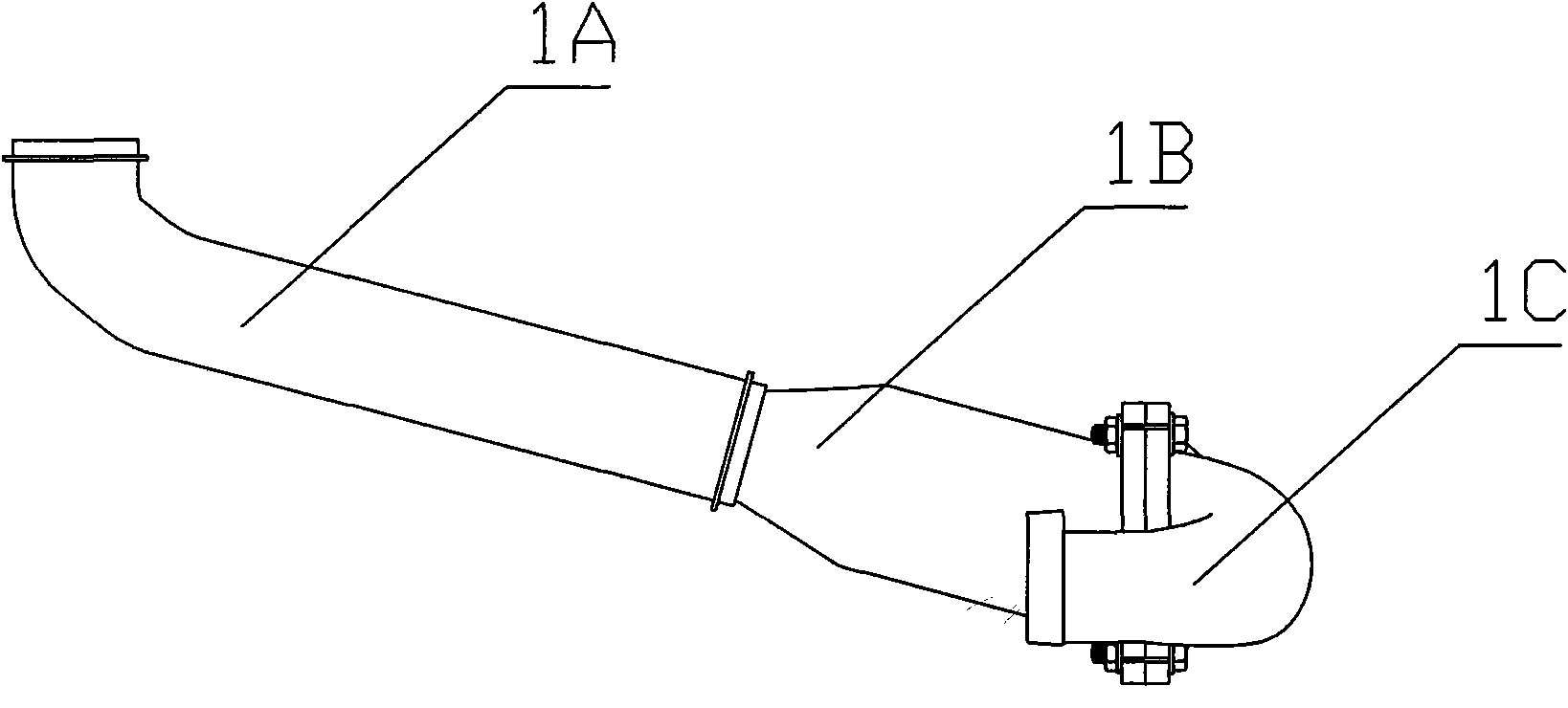

[0024] Such as figure 1 As shown, the steps for assembling an independent flush runner system for a combined water-saving toilet include, first, placing the figure 2 The injection pipe 1C in the regulating pipeline 1 shown in the figure is bonded or bolted to the interface of the water inlet hole of the pelvic cavity 2, so that the two components are integrated and sealed at the interface; the second is to bond the sewage pipeline 3 to the pelvic cavity 2 and sealed to form a complete independent flushing channel system; the third is to use a fixing plate or bracket to assist in fixing, so that the regulating pipe 1, the pelvic cavity 2, and the sewage pipe 3 are firmly connected into one.

[0025] The independent flushing channel system assembled above for the combined water-saving toilet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com