Photo acoustic sample detector with background compensation

An acoustic detector and detector technology, applied in the field of photoacoustic detectors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

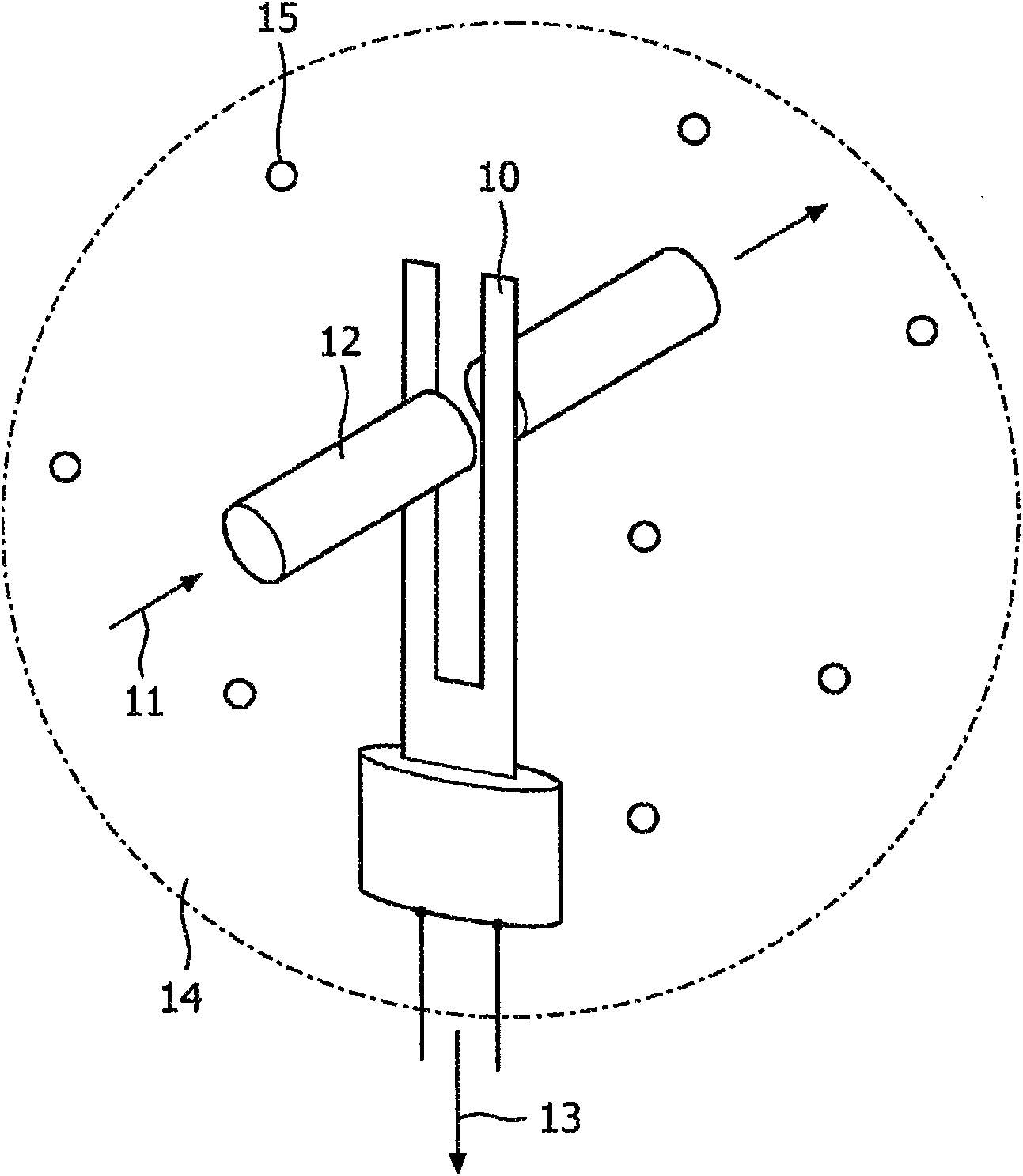

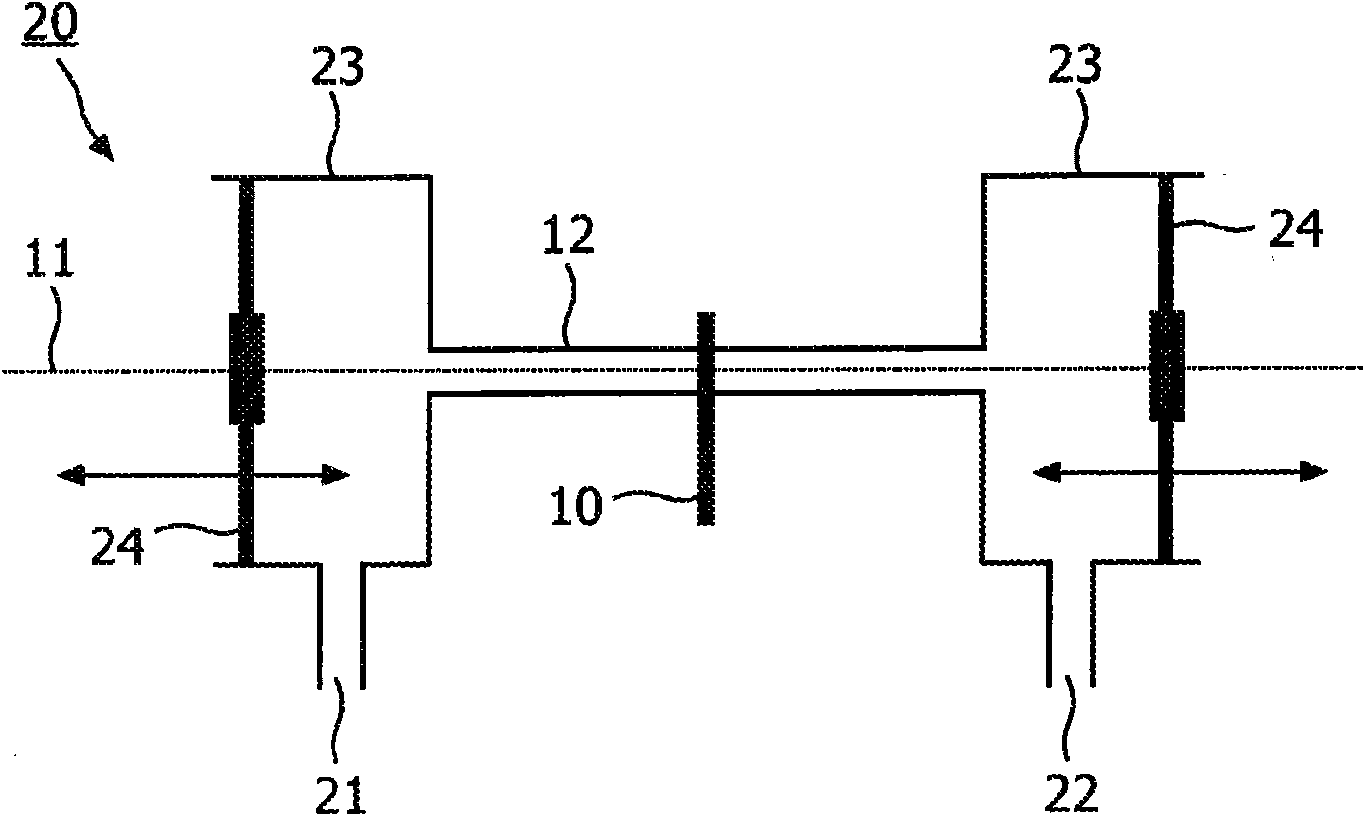

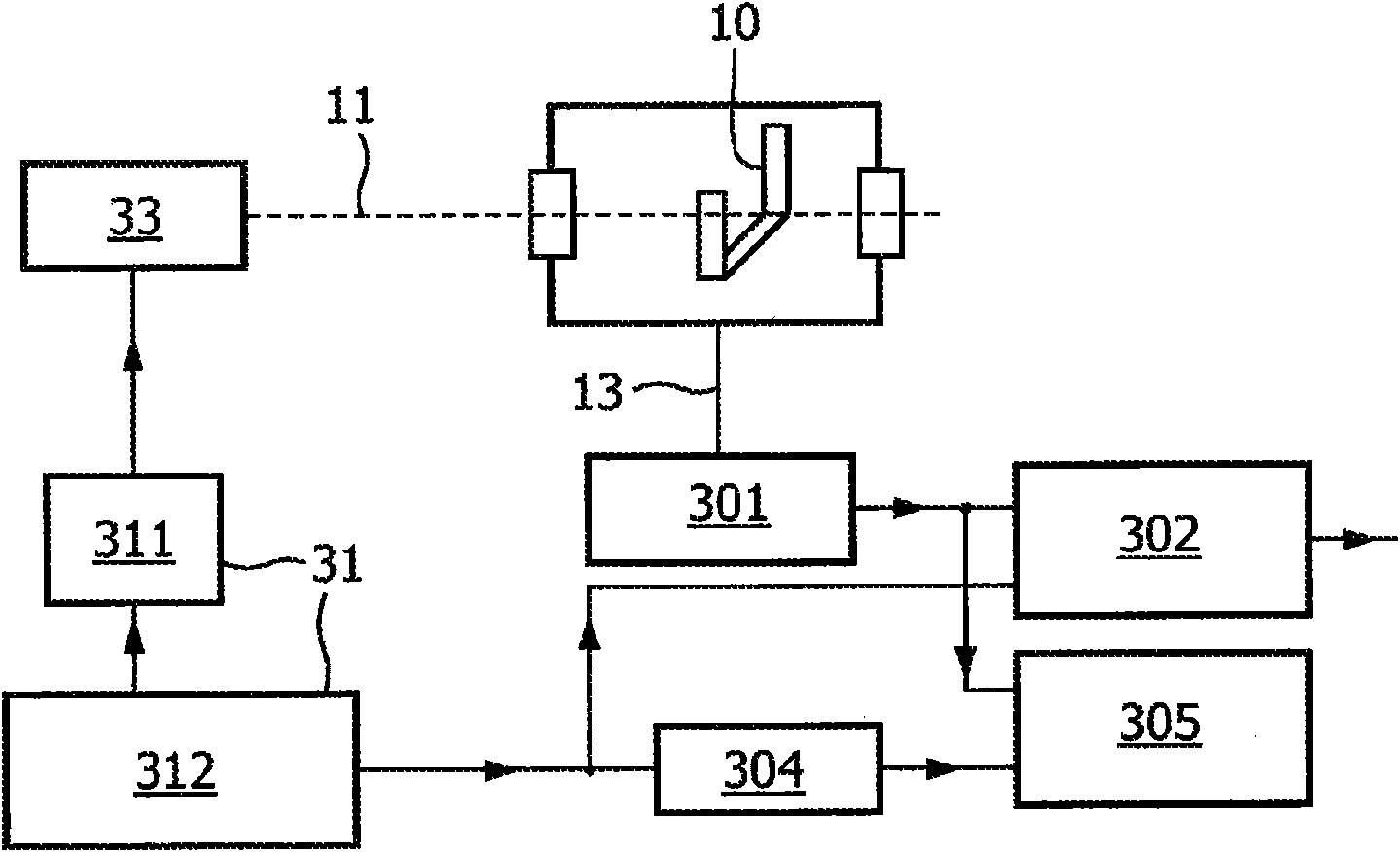

[0021] figure 1 A perspective view of a portion of a photoacoustic detector is shown. The amplitude modulated laser beam 11 passes through the gas mixture 14 . The gas mixture 14 includes a low concentration of sample molecules 15 . The laser beam 11 excites a part of the sample molecules. The return of the sample molecules from the excited state to the ground state results in a local temperature increase. The varying intensity of the laser light 11 causes pressure waves in the gas mixture 14 . Pressure waves can be detected as acoustic waves by means of a resonant pickup element, for example in the form of a piezoelectric tuning fork 10 . The tuning fork 10 may be a quartz tuning fork. The acoustic resonator 12 amplifies sound waves. The tuning fork 10 converts the sound signal into a detector signal 13, which is directed to the processing unit, where the reference image 3 with 4 Describe the processing unit in detail.

[0022] The tuning fork 10 has the advantage o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com