Automobile

A technology for automobiles and car bodies, which is applied in the direction of car bodies, body stability, and vehicle components, and can solve problems such as damage and threats to vehicle driving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

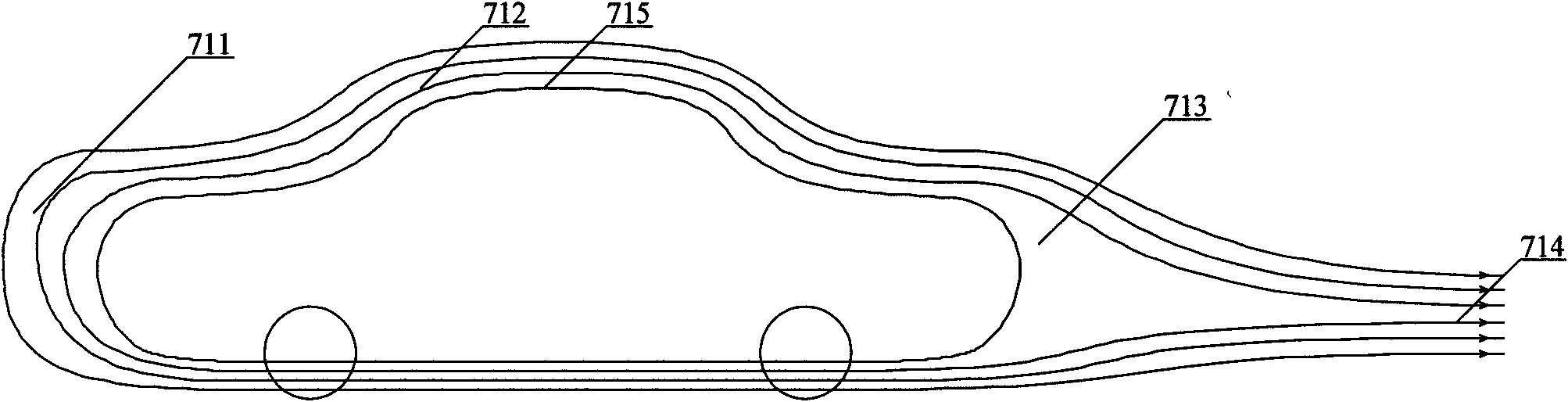

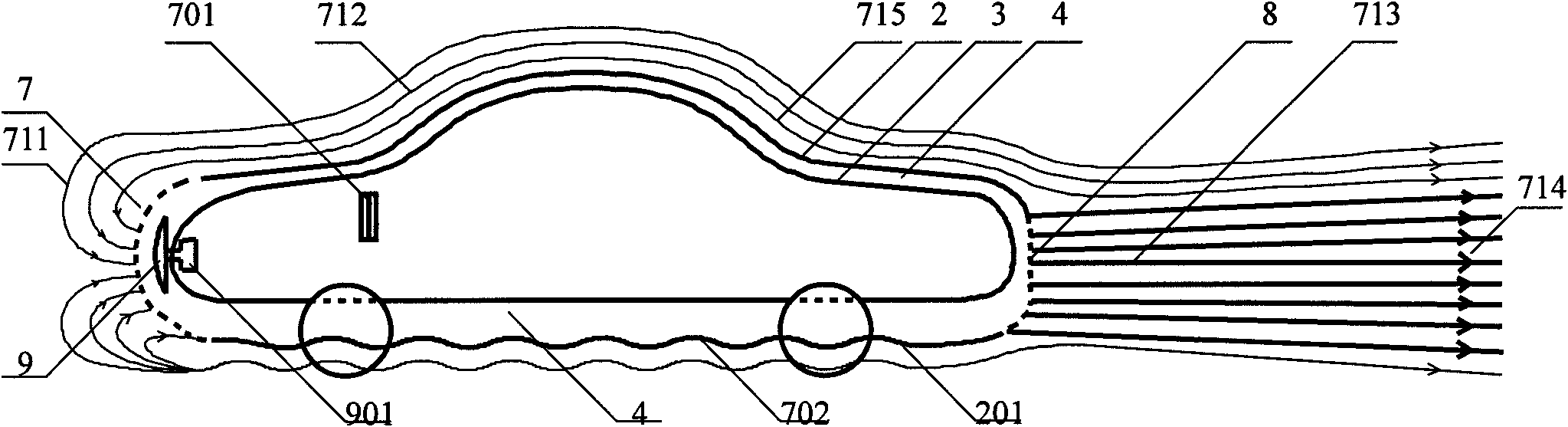

[0033] Such as figure 2 As shown, a car has a spoiler device added to the bottom of the car to increase the running speed and reduce energy consumption. A first inlet 7 is provided at the front end of the automobile. The first inlet 7 forms an annular fluid channel 4 that surrounds the vehicle body through a certain distance between the outer shell 2 and the inner shell 3, and the outlet 8 is provided at the rear end to penetrate back and forth. A rotating head 9 driven by a motor 901 is provided in the first inlet 7. At least one third side guide inlet 701 is provided around the vehicle body to communicate with the fluid channel 4, the bottom shell 2 is a spoiler 201 that is alternately concave and convex, and at least one second balanced inlet 702 is provided on the spoiler 201. The spoiler surface The distance between 201 and the ground is fixed, which does not affect the car's driving on normal roads. When the fluid passes through an unlimited distance between the spoiler ...

Embodiment 2

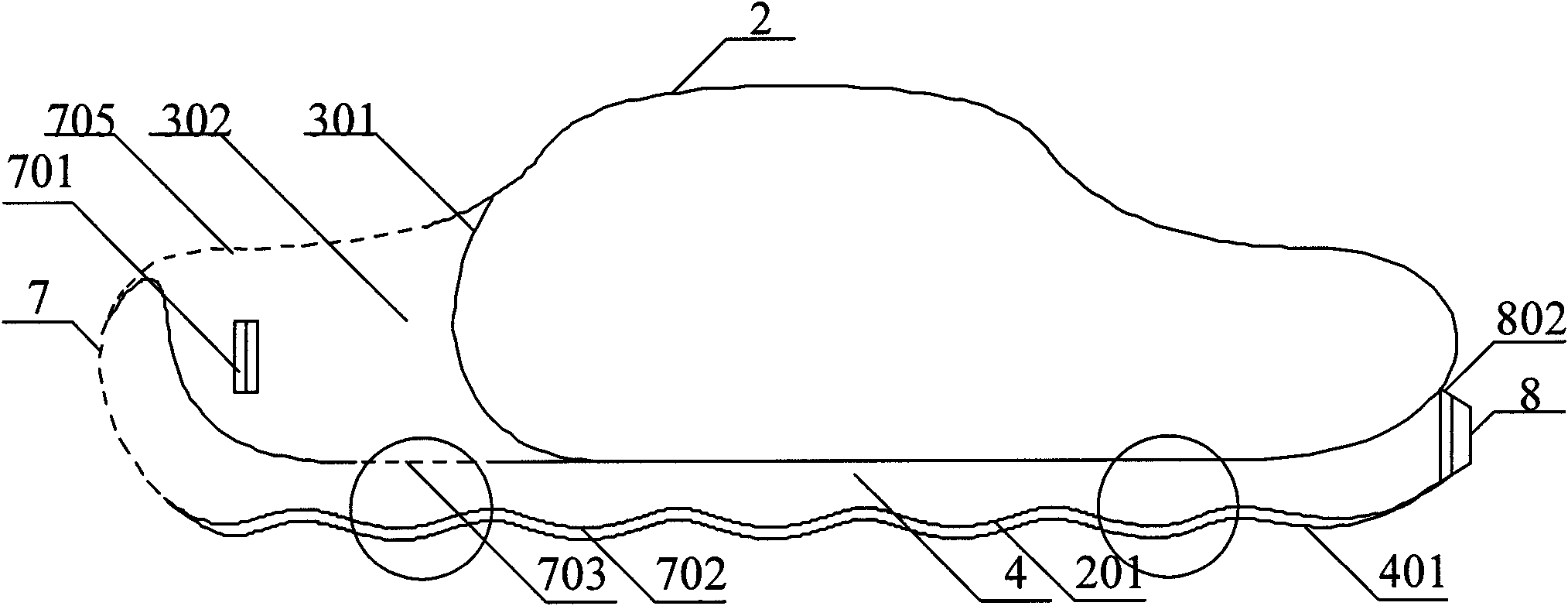

[0036] Such as image 3 As shown, it is a kind of automobile, and the structure can be most directly and simply applied to various existing car bodies. It achieves the energy-saving goal by fixing the improvement of the spoiler device under the vehicle to reduce the fluid resistance and lift resistance.

[0037] The car body includes a casing 2 and a spoiler 201 is added to the bottom of the casing 2 to reduce the distance between the ground and the road surface of the car body casing 2 to reduce the fluid flow rate in the lower part, thereby reducing lift resistance. Moreover, the surface of the spoiler 201 is further formed into a concave-convex shape, so that the path of the fluid when passing through the spoiler 201 is larger than the path of the upper part of the car shell 2, so as to form a top-down pressure difference when the vehicle is running, and eliminate the fluid Lift resistance.

[0038] If it is necessary to further reduce the resistance experienced by the vehicle ...

Embodiment 3

[0042] Such as Figure 4 , Figure 5 As shown, a car with a movable and controllable spoiler device at the bottom includes a car body 1. The car body 1 is provided with a spoiler device 2 at the bottom. The spoiler device 2 is connected to a movable rod 204 with adjustable vertical height. The inner bottom is connected, the spoiler device 2 is also arranged in a non-close contact with the car body 1, and an isolation layer 202 is also arranged in between, thereby forming an upper fluid channel 401 and a lower fluid channel 4, and the front end of the car body 1 is provided with a first An inlet 7 is provided with outlets 8 and 801 at the rear end. The first inlet 7 communicates back and forth with the lower fluid channel 4 and the outlet 8, and the first inlet 7 communicates with the upper fluid channel 401 and the outlet 801. The surface of the spoiler device 2 and the surface of the isolation layer 202 are both concave and convex spoiler surfaces 201 and 202, so that the path ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com