Control method of intelligent supplying system of crude fuel on blast furnace groove

A technology of supply system and control method, applied in the direction of blast furnace, blast furnace details, blast furnace parts, etc., which can solve the problems of affecting the volume ratio of the silo, affecting the forward movement of the feeding system on the trough, and unable to guarantee the safety of remote control of the unloading car, etc. , to achieve the effect of guaranteeing the control strategy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

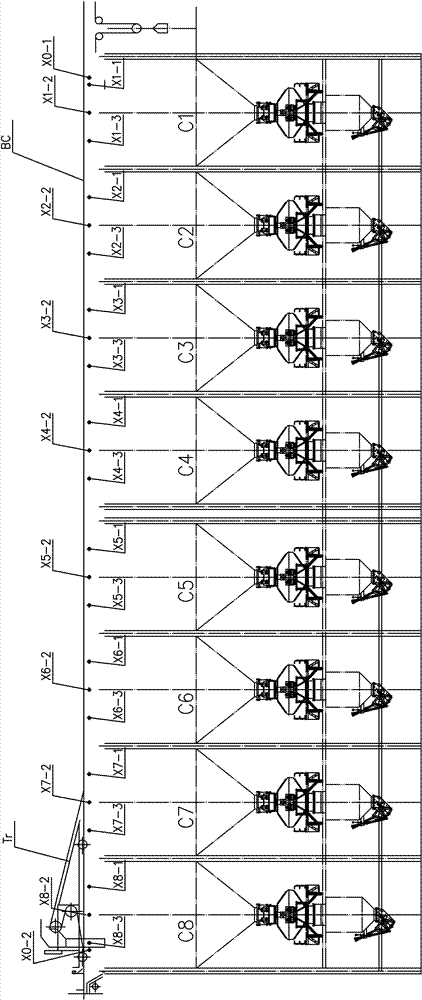

[0014] like figure 1 As shown, the raw material and fuel intelligent supply system on the blast furnace tank includes the belt conveyor BC on the tank, a plurality of bunkers ( figure 1 C1~C8 in), the control computer, the belt conveyor BC on the trough is located at the upper part of the silo entrance, and the upper part of each silo is provided with a corresponding limit sensor (at figure 1 In Xa-b), there is a material level gauge in the silo, and the signals of the limit sensor and the material level gauge are transmitted to the control computer. The unloading truck Tr is located on the belt conveyor BC on the groove.

[0015] In a preferred embodiment, there are three limit sensors corresponding to each silo, and the front limit sensor (located at X0-2) and the rear limit sensor (located at X0 -1).

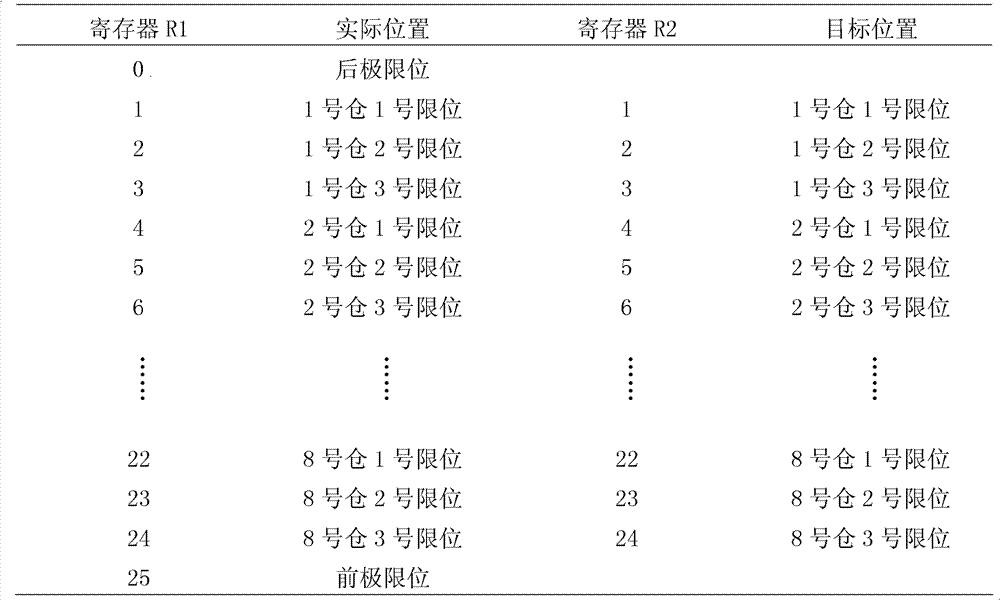

[0016] A control method for an intelligent supply system of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com