Conductor bundle detection system

A detection system and wire harness technology, applied in the field of wire harness detection devices, can solve the problems of poor real-time performance, poor detection ability, unreliable communication, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

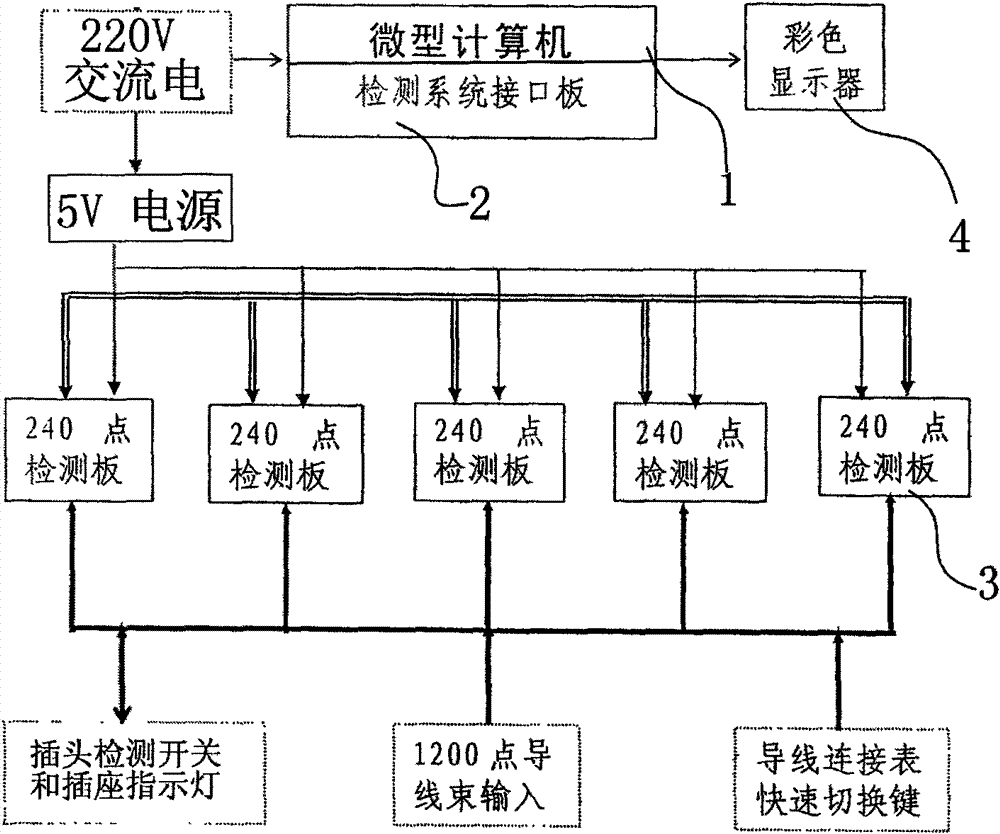

[0021] see figure 1 , The wire harness detection system provided by the present invention is mainly composed of a main control computer 1 , an interface board 2 and a detection board 3 .

[0022] The interface board 2 is the link between the detection board 3 and the main control computer 1 . The main control computer manages several detection boards 3 through the interface board 2, so that they can act according to the instructions of the control computer 1 to realize the detection work of the wiring harness. It can be connected to a color display 4 to visually display the corresponding detection results.

[0023] When the interface board 2 is installed, it is directly inserted into the ISA bus slot of the microcomputer, and is fixed on the ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com