Oil-water separator

The technology of oil-water separator and separation cylinder is applied in liquid separation, separation method, semi-permeable membrane separation and other directions, which can solve the problems of complex structure of automatic drainage mechanism, failure of timely drainage, and loss of automatic drainage function, etc., so as to improve work efficiency. Efficiency and working life, simple structure, high reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

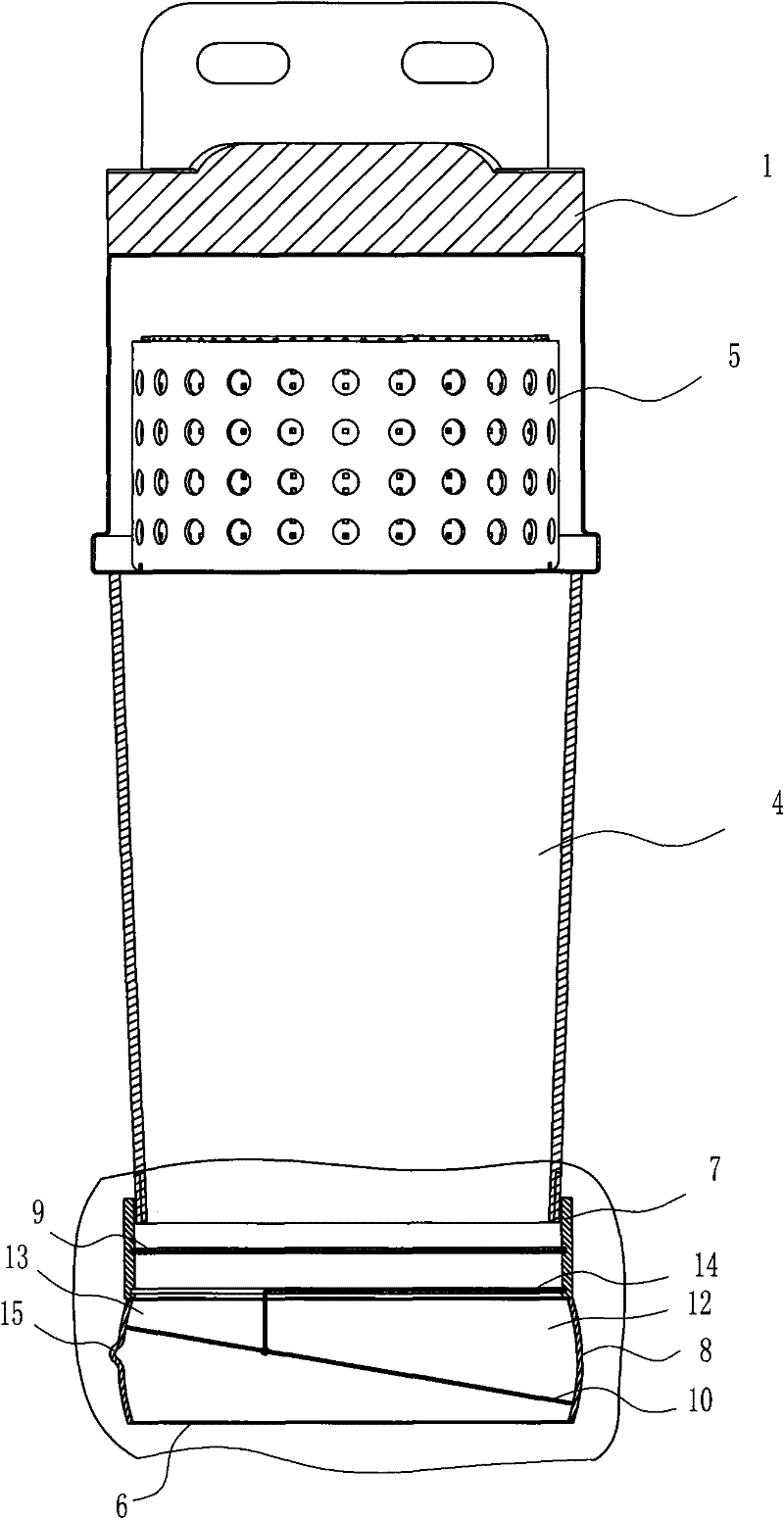

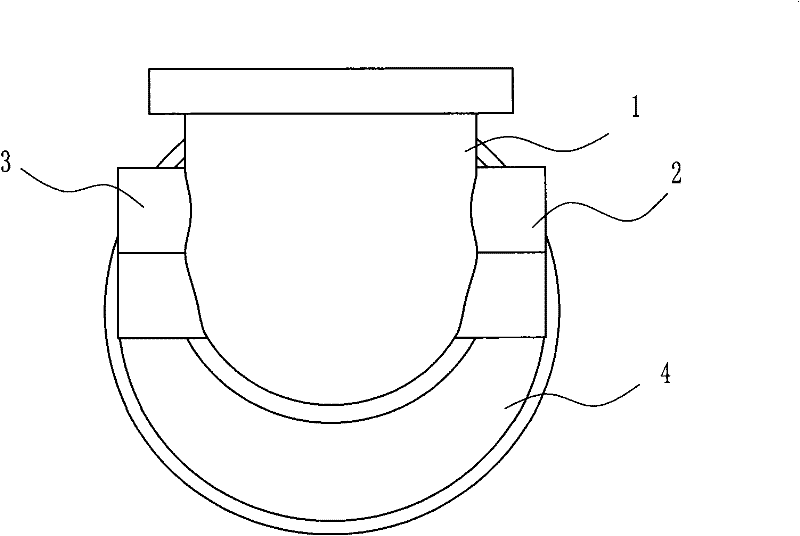

[0023] Embodiment one: see Figure 1~5 As shown, an oil-water separator includes a body and a water discharge mechanism at the bottom of the body. The top of the body is a base 1 provided with an oil inlet 2 and an oil suction port 3. Below the base 1 is a separation cylinder 4. The base 1. A water retaining plate 5 is provided on the top of the separation cylinder 4. The top inner wall of the water discharge mechanism is provided with an internal thread, which is screwed with the external thread at the bottom of the body. The bottom of the water discharge mechanism is provided with a water outlet 6. The water discharge mechanism The mechanism includes a water storage unit 7 and a water discharge unit 8;

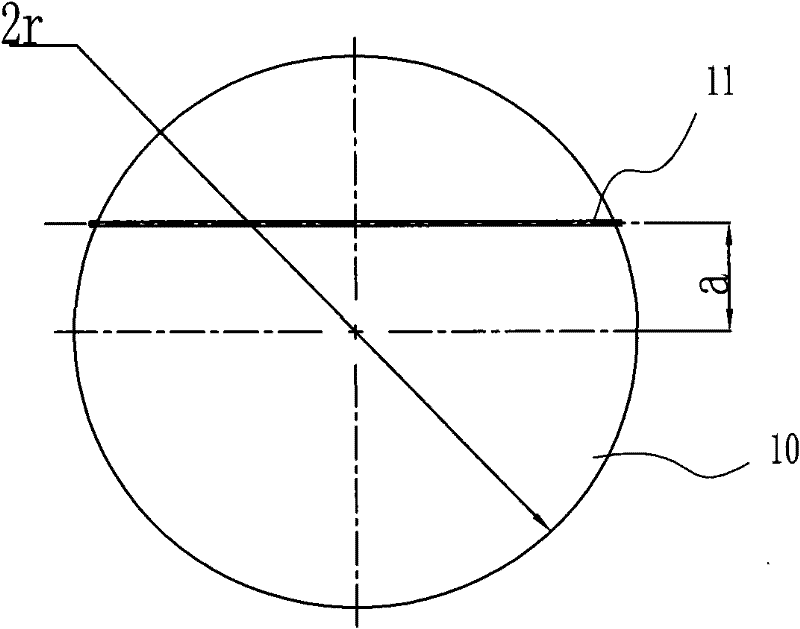

[0024] The top of the water storage part 7 communicates with the inner cavity of the separation cylinder 4, and an annular clamping groove is arranged in the described water storage part 7, and an oil-water separation membrane 9 is arranged in the annular clamping groove (th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com