Blast-furnace gas hydrogen chloride purifying and absorbing compound device and method

A blast furnace gas and composite device technology, which is applied in the fields of combustible gas purification, combustible gas purification/renovation, petroleum industry, etc., can solve the problems of hydrogen chloride-containing components, corrosion of gas pipelines, etc., and achieves good economic and environmental benefits, The effect of reducing pollution and solving corrosion phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

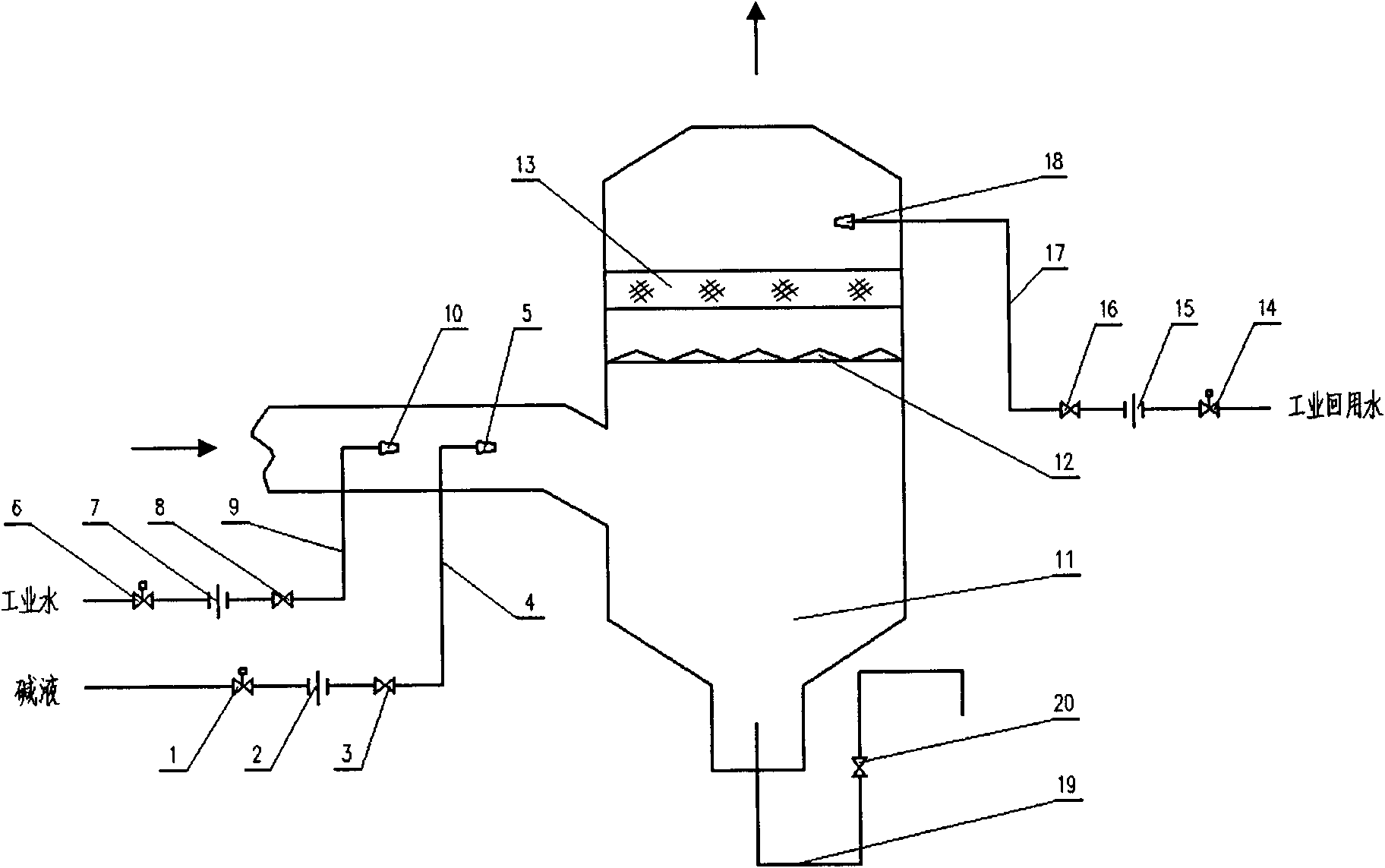

[0012] The device of the present invention comprises lye solenoid valve 1, lye blind valve 2, lye gate valve 3, lye distribution pipeline 4, lye nozzle 5, industrial water solenoid valve 6, industrial water blind valve 7, industrial water Gate valve 8, industrial water transmission and distribution pipeline 9, industrial water nozzle 10, liquid removal tower shell 11, air distribution plate 12, gas-liquid separation packing 13, industrial reuse water solenoid valve 14, industrial reuse water blind plate valve 15, industrial return water Water gate valve 16, industrial reuse water distribution pipeline 17, industrial reuse water nozzle 18, drainage pipeline 19, drainage gate valve 20, the above components are sequentially connected by flanges; unpurified blast furnace gas is sprayed with industrial water, lye After the mechanical water droplets are intercepted by the spray mixing and dehydrating tower, the clean blast furnace gas is sent to the user, and the discharged water is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com