Fuel filling and filtering system of paving machine

A fuel filling and filtration system technology, applied in the direction of charging system, mechanical equipment, engine components, etc., can solve the problems of low productivity, failure to meet requirements, ineffective exhaust and filtration, etc., and achieve long service life, Guaranteed quality, easy to promote the effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

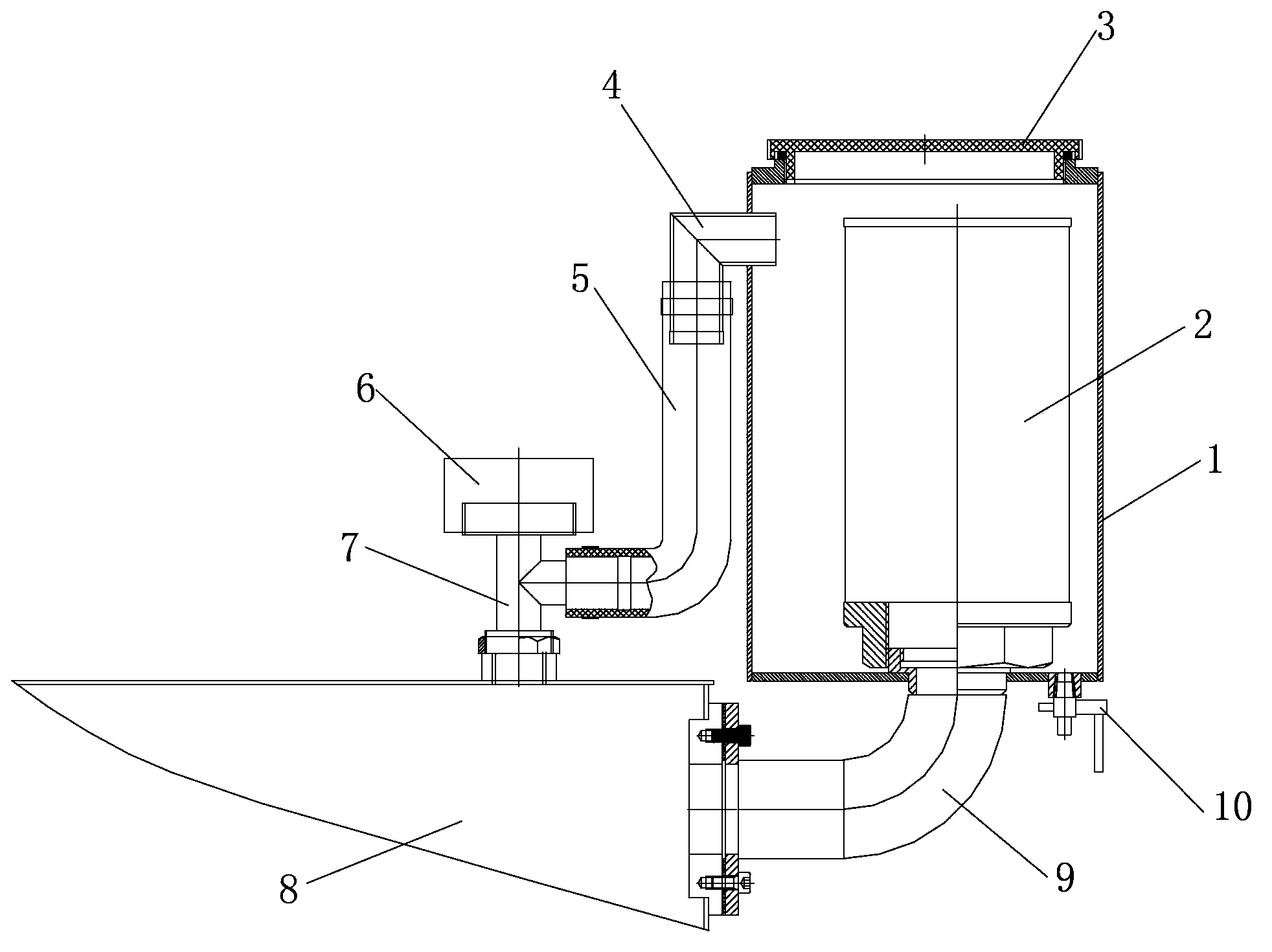

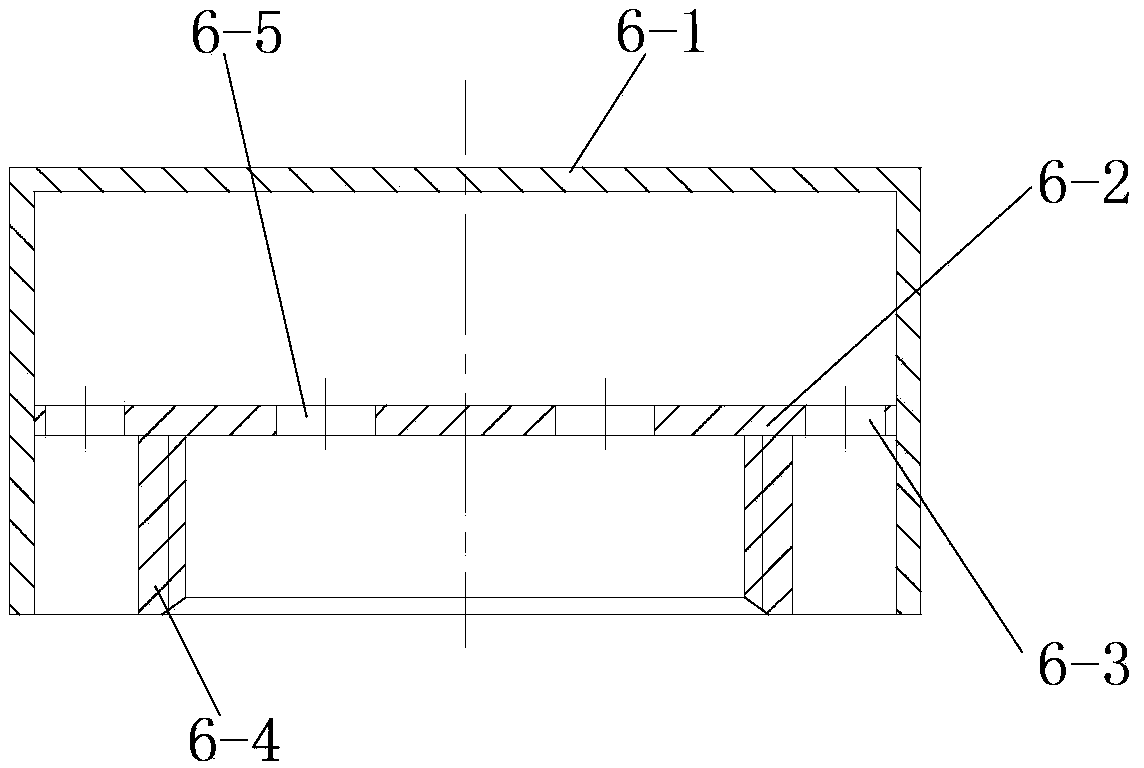

[0024] like figure 1 and figure 2 The shown fuel filling filter system for a paver includes a container 1, a cover 3 is arranged on the upper part of the container 1, a cylindrical filter element 2 is vertically arranged in the container 1, and the lower end of the filter element 2 is The output port of the paver is connected with the fuel tank 8 of the paver through the connecting pipe one 9, and a tee joint 7 is installed on the fuel tank 8 of the paver, and the connection port one of the tee joint 7 is connected with the fuel tank 8 of the paver The connection port two of the three-way joint 7 communicates with the upper part of the container 1 through the connection pipe two 5, and the three-way connection port 7 of the three-way joint 7 is connected with an air respirator 6; the air respirator 6 includes a hollow The air respirator body 6-1, the air respirator body 6-1 is cylindrical, the inner wall of the air respirator body 6-1 is provided with a partition 6-2, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com