Simple perforating device for outer rubber layer of automobile air conditioner rubber tube

A technology of automobile air conditioner and drilling device, which is applied in metal processing and other directions, can solve the problems of inconvenient operation, difficult maintenance of wearing parts, complex structure, etc., and achieve the effect of convenient operation, easy debugging and maintenance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

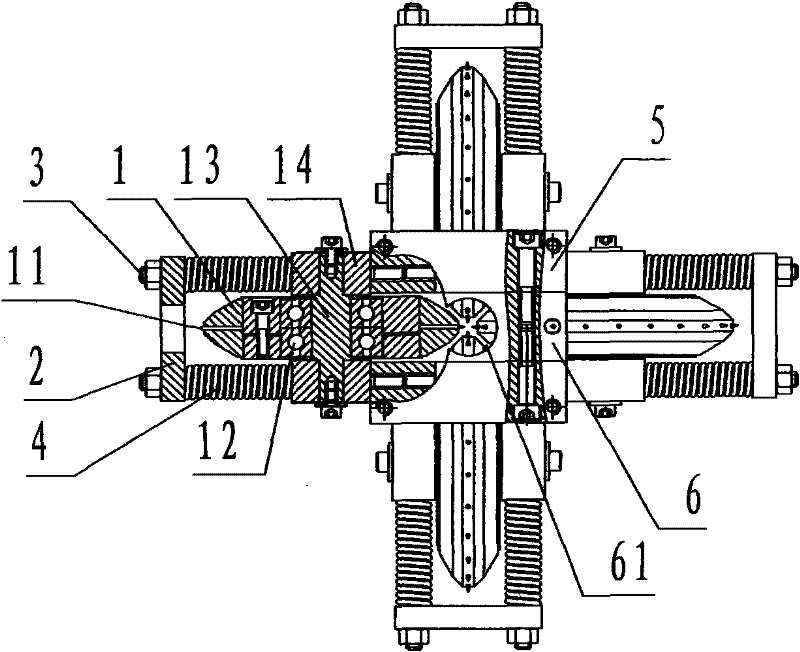

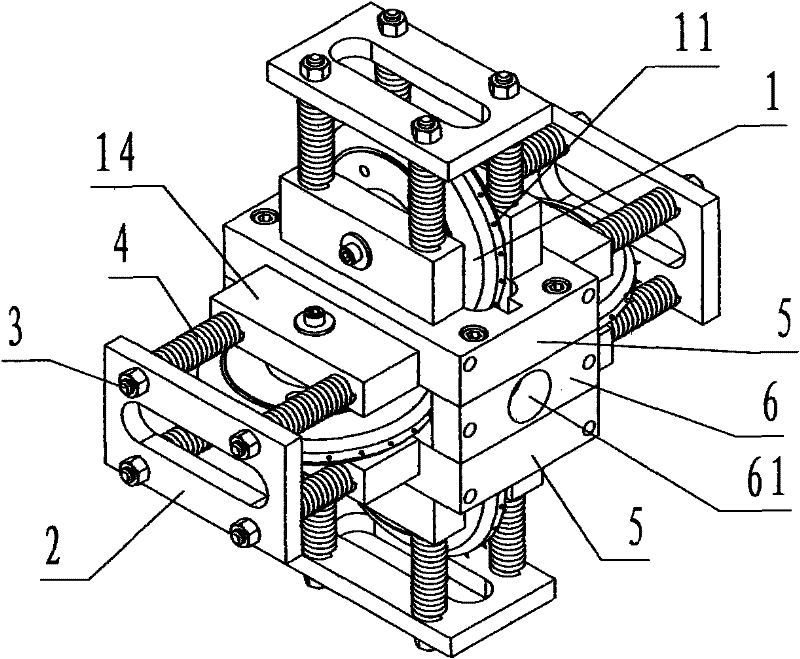

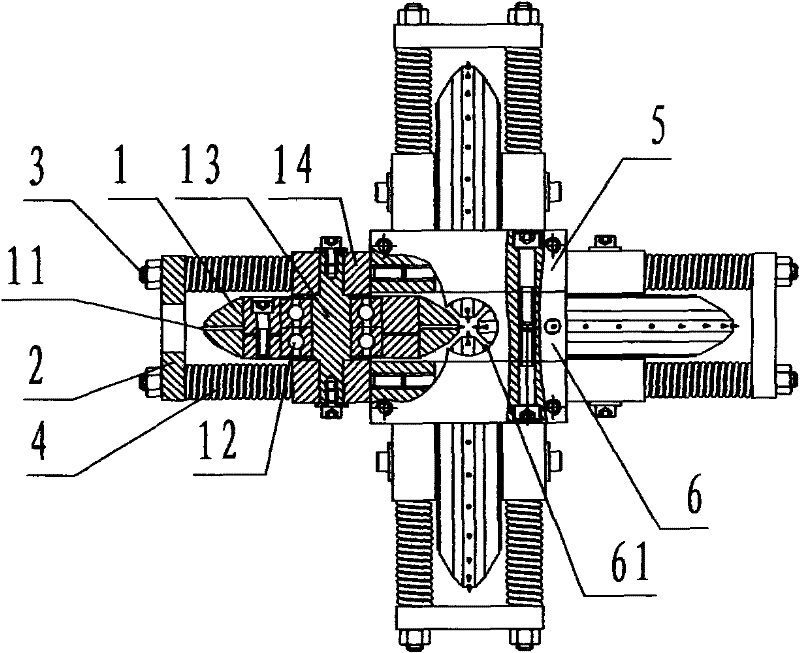

[0023] refer to figure 1 , figure 2 , a simple punching device for the outer rubber layer of an automobile air-conditioning rubber hose of the present invention, comprising a pin wheel 1, a beam plate 2, a guide rod 3, a spring 4, a support plate 5, and a liner block 6, wherein: the pin wheel 1 is a steel wheel with a trapezoidal rim section; the rim circumference of the pin wheel is evenly distributed with conical needles 11 for puncturing and punching along the radial direction; the hub of the pin wheel 1 is equipped with a bearing 12, and the bearing Wheel shaft 13 is housed in the axle hole of 12, and the two ends of wheel shaft 13 are respectively fixedly connected in the support hole of bearing seat 14 of one end; Bearing seat 14 is the steel plate of rectangle; 13, the side of the long side of the plate of the bearing seat 14 is provided with two through holes that are equal in diameter and hole distance to the two beam plate adjustment holes on the long side of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com