Pick-up device for picking up a tubular knitted article from a circular knitting machine for hosiery or the like and for transferring it to a unit adapted to perform additional work on the article

一种圆型针织机、拾取装置的技术,应用在具有单独动作针的纬编针织用圆机、针织、纬编针织等方向,能够解决纱线缠结等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

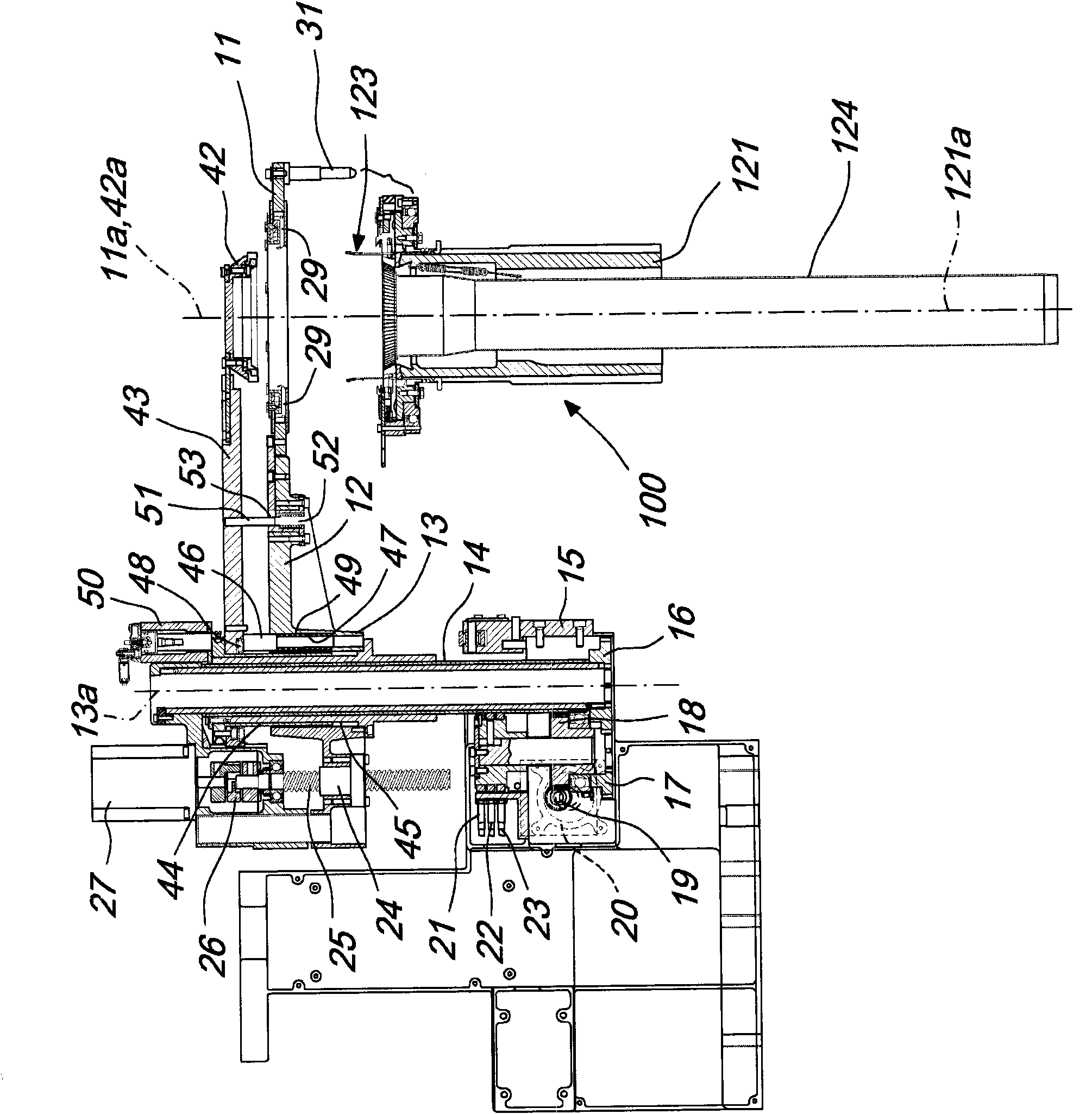

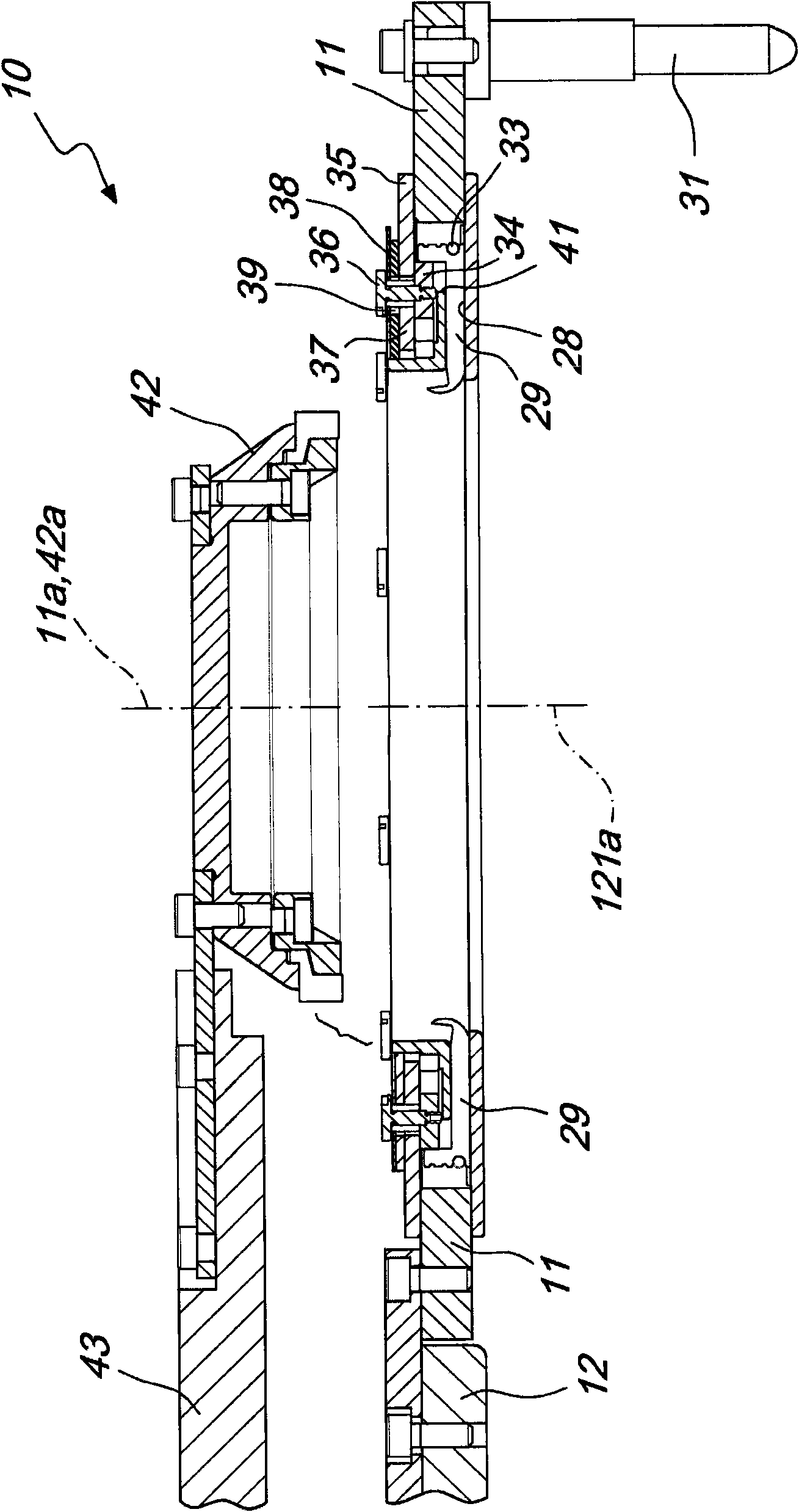

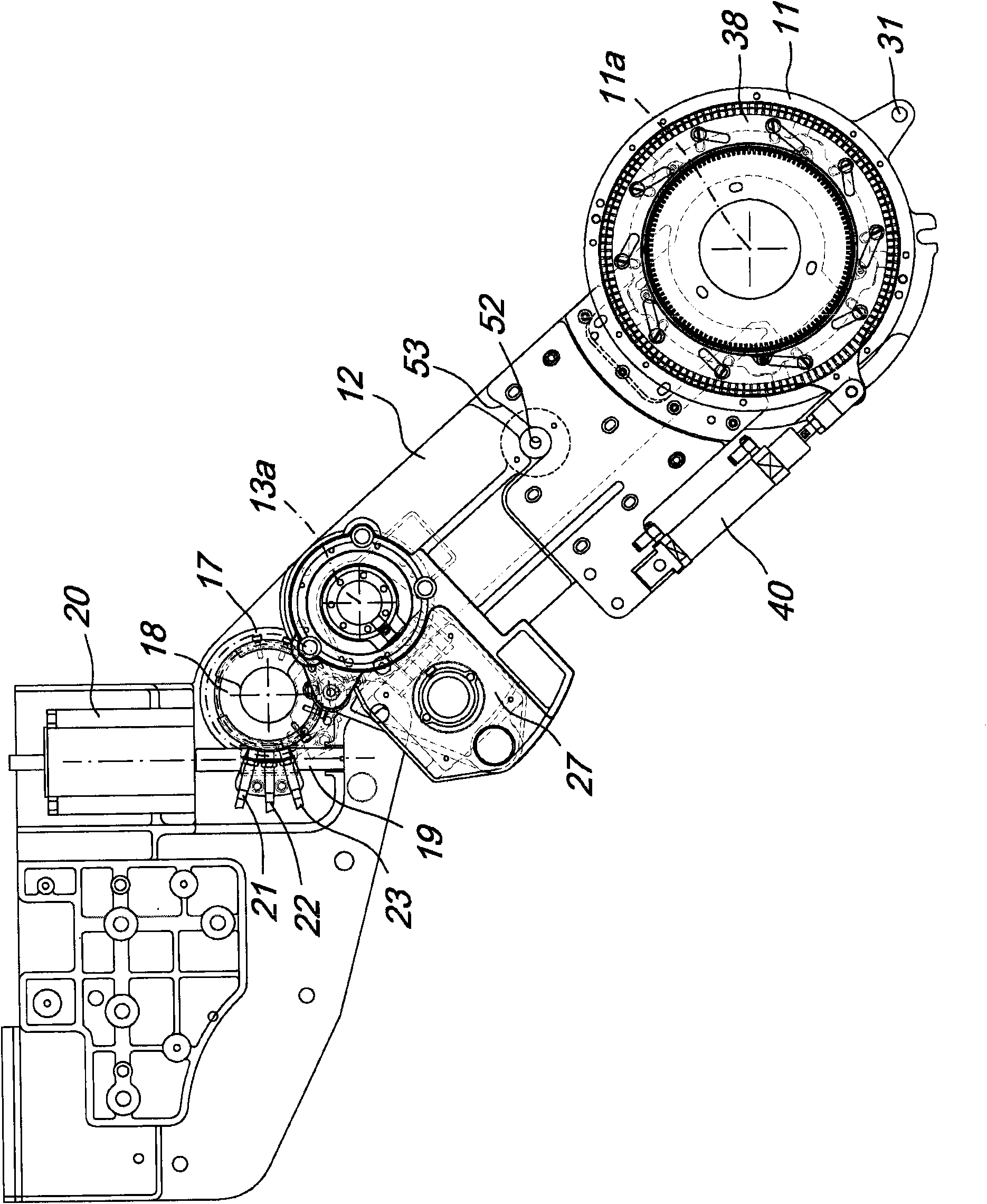

[0036] The device according to the invention is shown applied to a single-cylinder circular hosiery knitting machine, generally designated by the reference number 100, but may also be used to extract from needles arranged in the lower cylinder of a double-cylinder circular hosiery knitting machine. Picking up the item 101 or even picking up the item from the needles arranged in the upper cylinder of the double cylinder circular hosiery knitting machine. In the latter case, however, the device according to the invention must be installed upside down with respect to what is shown in the drawings.

[0037] Referring to the accompanying drawings, a single-cylinder circular hosiery knitting machine 100 designed to use the pickup device according to the invention comprises a cylinder 121 whose axis 121a is oriented vertically. A plurality of axial slots 122 are formed on the side surface of the needle cylinder 121, each slot housing a needle 123 that can be actuated to reciprocate a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com