Volume measurement filling machine

A filling machine and volume technology, applied in the direction of liquid materials, packaging, packaging items, etc., can solve the problems of slowing down the working speed of the filling mechanism, hindering the development of packaging technology, restricting development, etc., to improve the efficiency of metering and packaging and the automation of metering and packaging. degree, convenient for daily cleaning and maintenance, and the effect of high automatic control ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

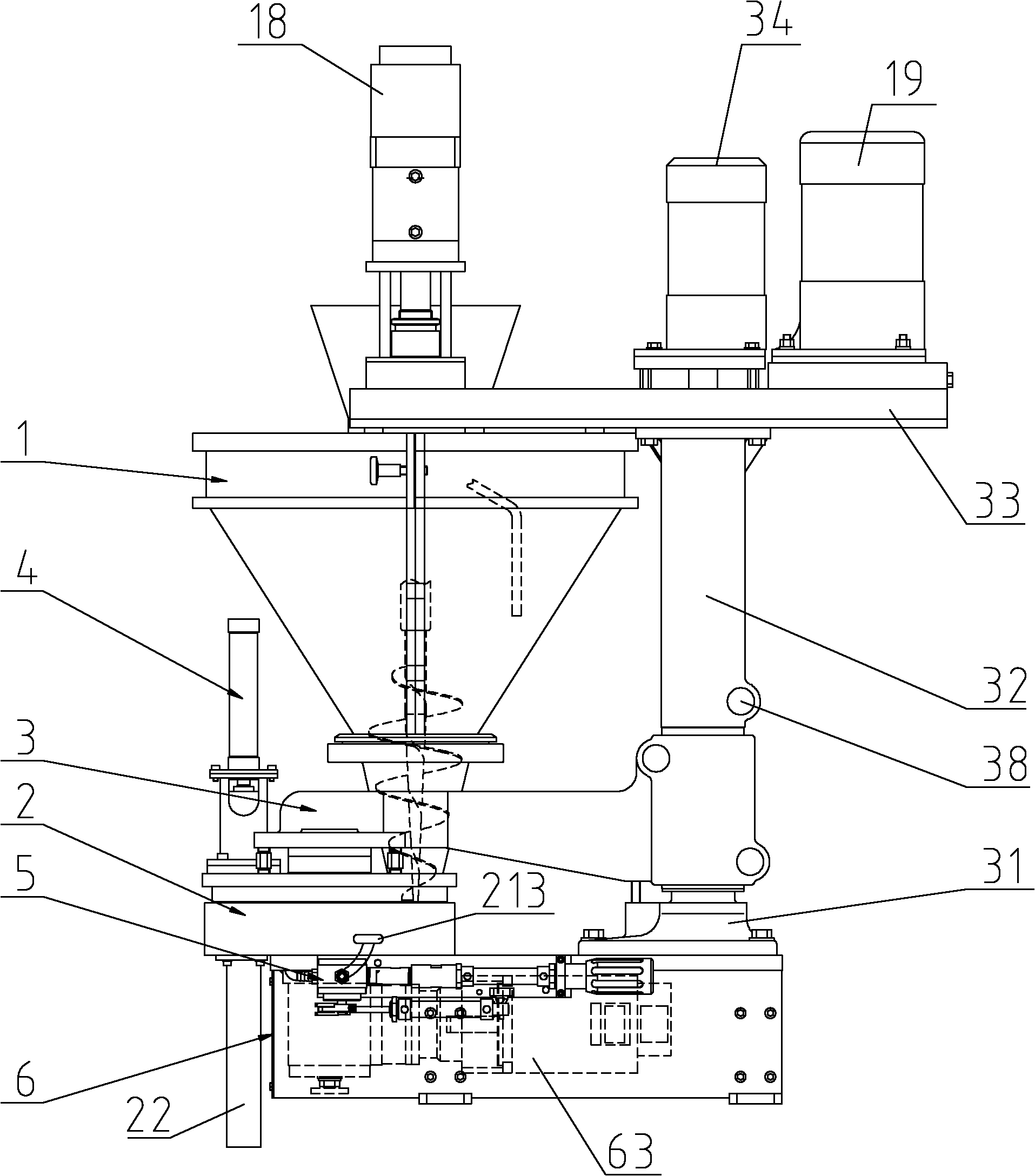

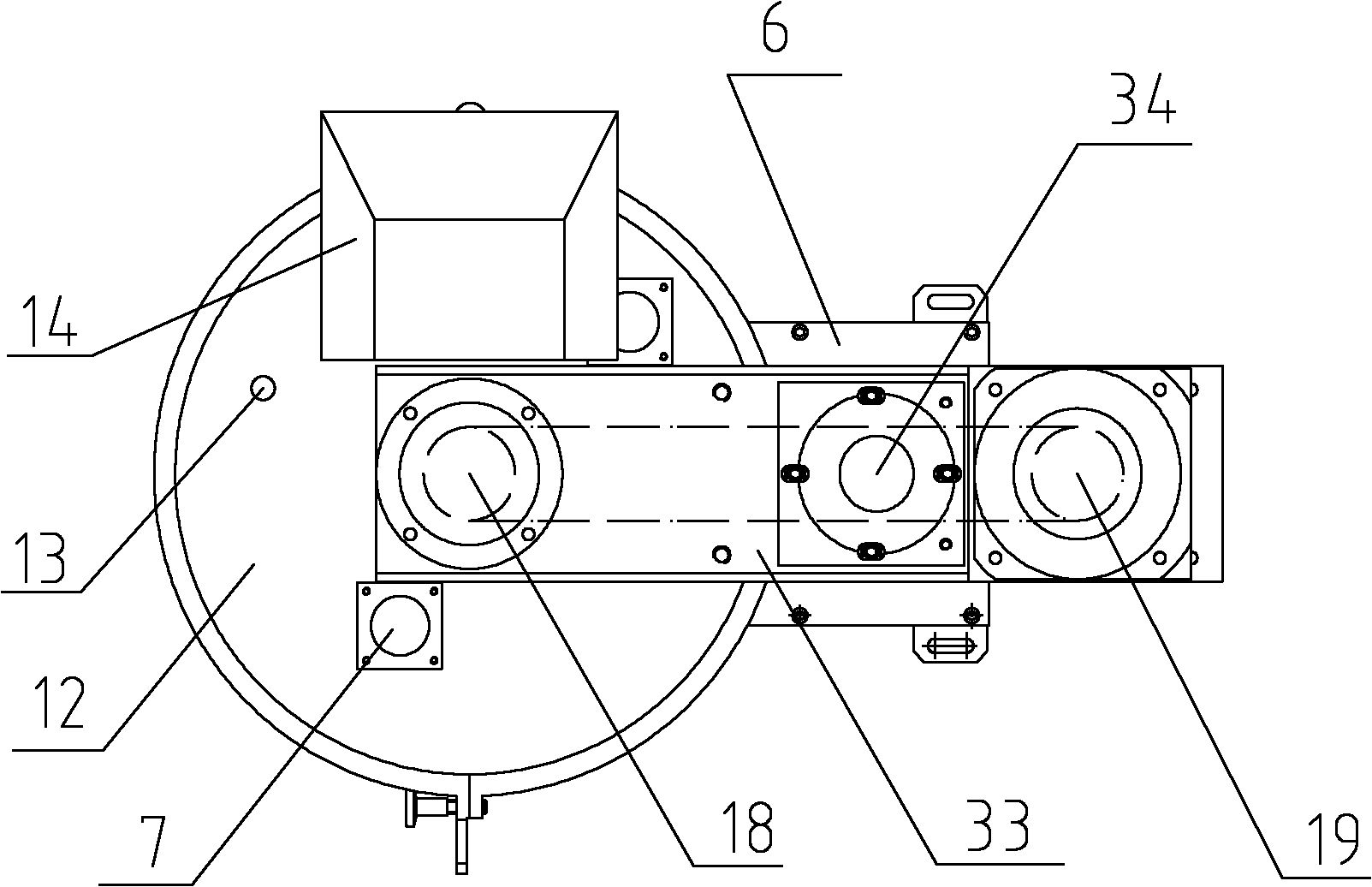

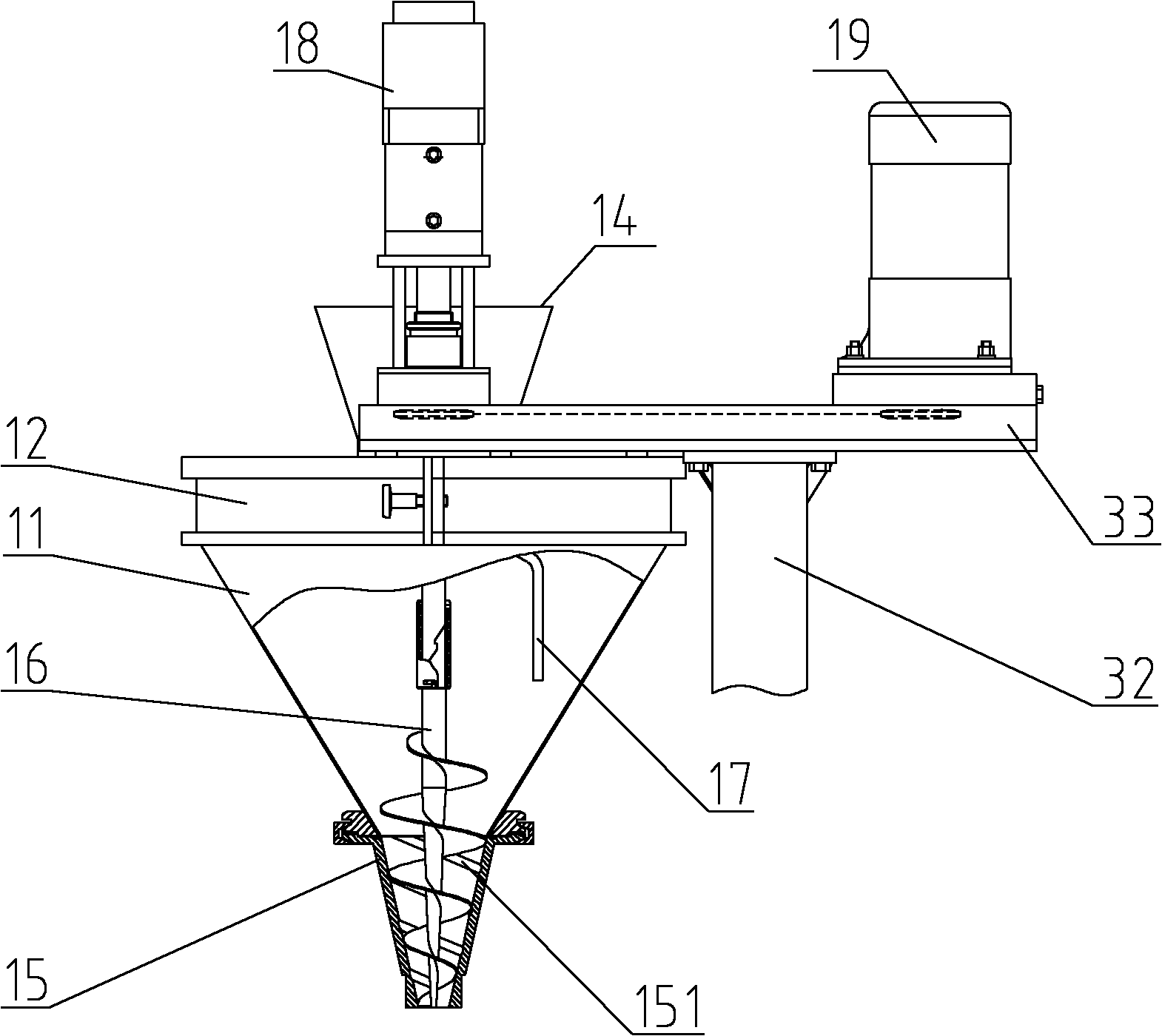

[0035] see Figure 1 to Figure 9 , the present invention, that is, a volume metering filling machine, comprising a base case 6, a feeding device 1, a metering device 2, a volume adjustment device 3, a punching device 4, a juice replenishing device 5 and CIP cleaning Head 7, wherein the base box 6 includes a box body composed of a main board 61 and a side plate 62, a servo motor 63 arranged inside the box body, an indexing detection disk 64 connected with the servo motor 63 and a box body arranged on The box seat 65 of bottom surface.

[0036] The feeding device 1 includes a certain amount of storage hopper 11, a bucket cover 12 that is arranged on the upper end of the quantitative storage hopper 11 and is provided with a material level device 13 and a feeding port (not shown), one is arranged on the top surface of the bucket cover 12 and A receiving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com