Tobacco lamina formula state library leaf group execution formula management and control system and method thereof

A technology for formulating and stacking leaves, applied in tobacco, tobacco preparation, application, etc., can solve the problems of low accuracy and large workload, and achieve the effect of strict control process, improve work efficiency, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

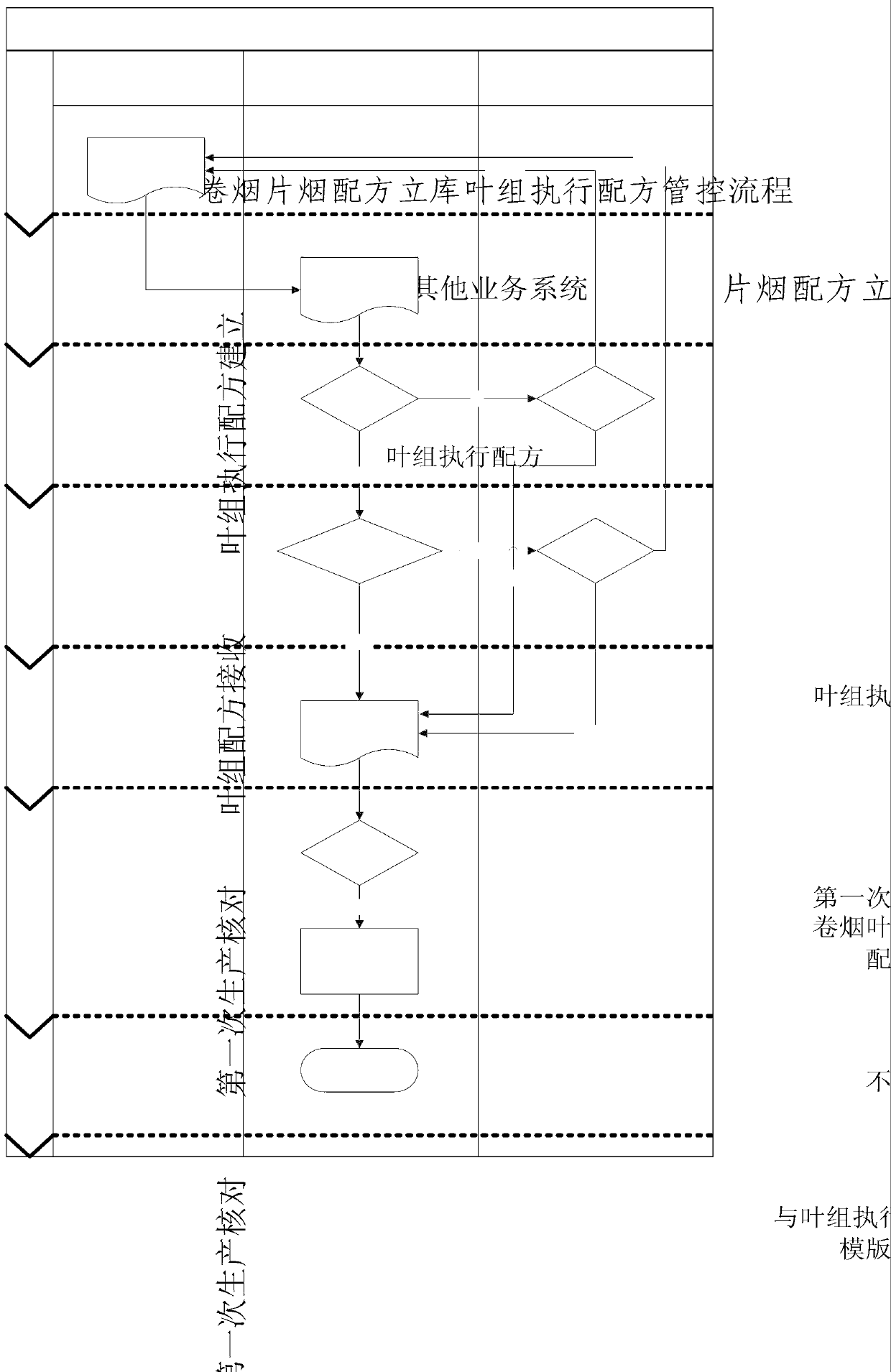

[0032] The invention provides a management and control system for the leaf group of the leaf group of the tobacco formula storehouse, the structure is as follows: figure 1 As shown, it includes the leaf group execution formula unit, the laminar tobacco formula storage inspection unit and the warehouse-out invalidation unit. details as follows:

[0033] The leaf group execution recipe unit is used to establish a leaf group execution recipe check template and a leaf group execution recipe check.

[0034]The sheet tobacco enters the sheet tobacco formula library inspection unit, when the sheet tobacco enters the sheet tobacco formula library, it identifies the sheet tobacco through the identification device, and then compares the identified information with the leaf group execution formula. Lamina cigarettes conforming to the formula executed by the leaf group are refused to enter the warehouse, and cigarettes exceeding the quantity of the formula are refused to enter the wareho...

Embodiment 2

[0041] In this embodiment, when establishing a leaf group execution recipe checking template and checking the leaf group execution recipe, it is analyzed according to the specific situation of whether it is the first time to produce a cigarette. When producing a cigarette for the first time, first manually check the leaf group execution formula transmitted from other systems, after the check is passed, set the leaf group execution formula as the available leaf group execution formula, and set the leaf group execution formula The leaf group execution formula is used as the leaf group execution formula check template for subsequent leaf group execution formula checks during the cigarette production; after checking, the relevant users of the leaf group execution formula source system cannot be notified, and the formula is corrected in the source system and re-written. Transfer to the management and control system of the tobacco sheet formula library, and check again according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com