Jack symmetric precompaction construction method for hanging basket girders for bridge hanging basket suspension casting construction

A construction method and the technology of basket girders, which are applied in the field of bridge construction, can solve problems such as difficult observation, inaccurate control of preloading data, and large consumption of machinery and manpower, so as to facilitate construction control and adjustment, speed up preloading work efficiency, The effect of saving preloading construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

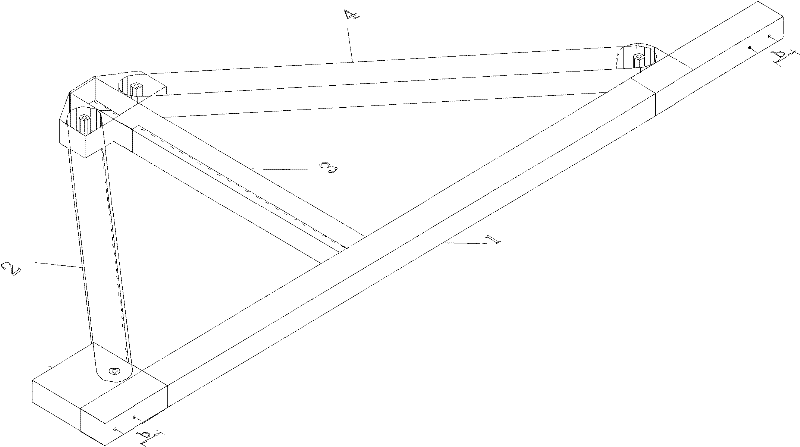

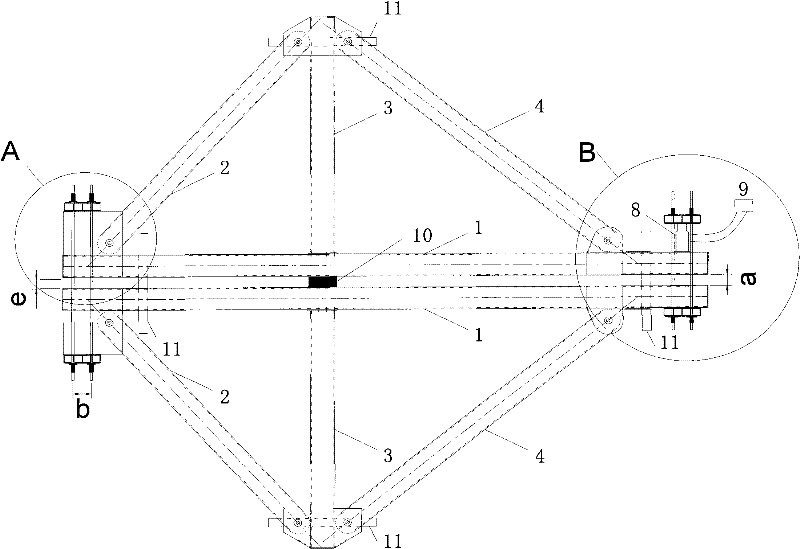

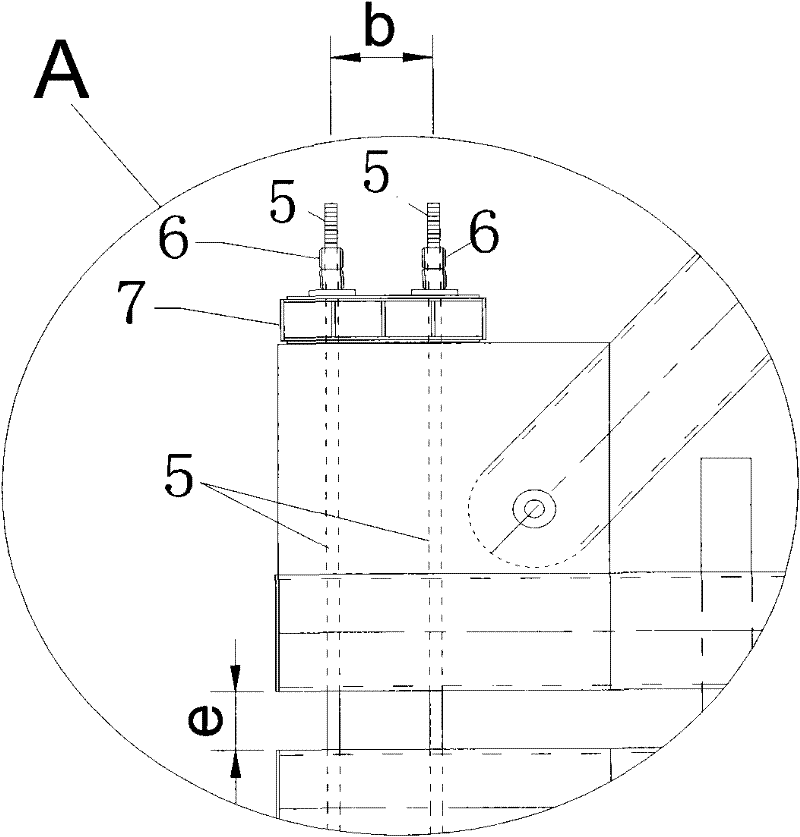

[0034] see figure 1 , the jack symmetric preloading construction method of hanging basket girders used in bridge hanging basket hanging construction, the preloaded triangular hanging basket girders include four main pieces: web bar 3, cross bar 1, short oblique bar 2, and long oblique bar 4 There are two bolt holes arranged side by side at the rear anchor point of the hanging basket truss; two bolt holes are arranged side by side at the loading end, and the diameter of the bolt hole is 35mm. It is believed that the distance between the two bolt holes is b=300mm.

[0035] The specific preloading operation includes the following steps:

[0036] (1) Select a pre-pressing site with an area of 15m×15m or more, level and compact the pre-pressing site, and reserve it;

[0037] (2) Assemble the parts web bar 3, cross bar 1, short oblique bar 2, and long oblique bar 4 into two identical triangular hanging basket trusses;

[0038] (3) The cross bars 1 of the two hanging basket truss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com