Preloading structural part for high and large formwork support system

A support system, stacking preloading technology, applied in the connection of formwork/formwork/work frame, formwork/formwork/work frame, on-site preparation of building components, etc., can solve the inaccurate control of preloading data , the collapse of the formwork support system, the extension of the construction period and other problems, to achieve the effect of speeding up the preloading work efficiency, large unit area load, and reducing the lifting workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

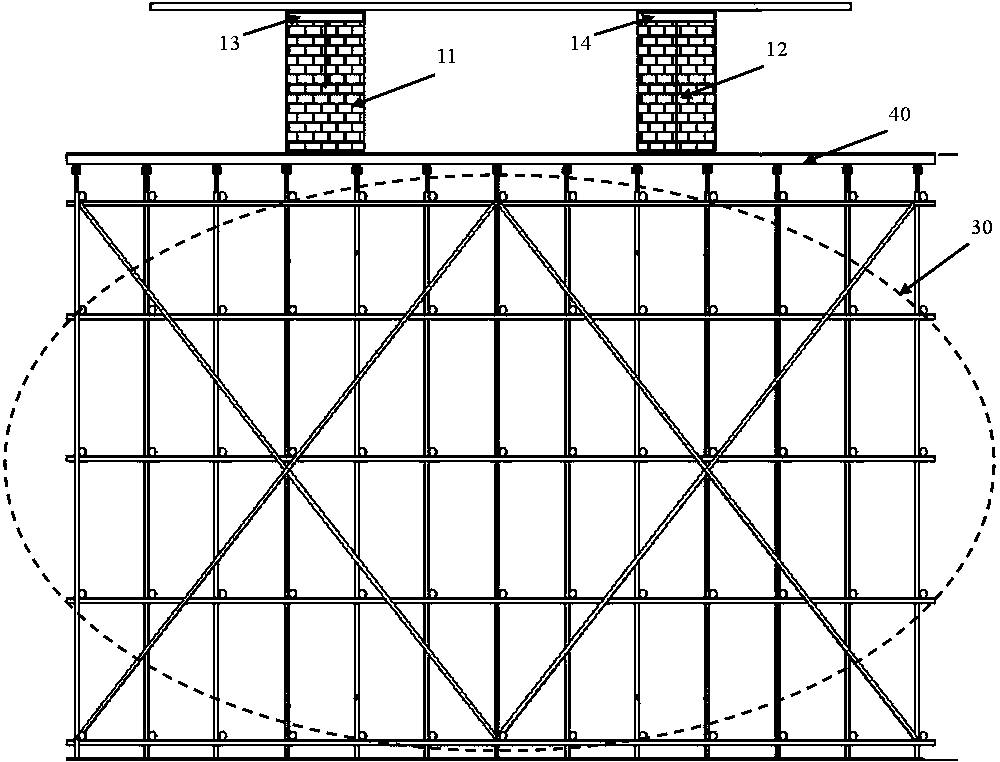

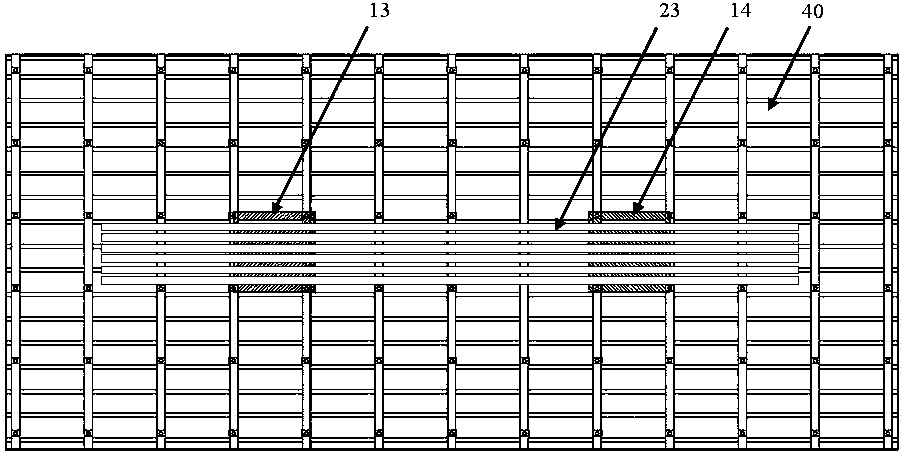

[0029] see figure 1 , used for the stacked preloaded structural parts of the tall formwork support system, including brick pier components and preloaded load components;

[0030] The brick pier assembly is composed of a first brick pier block 11 and a second brick pier block 12; wherein, the first brick pier block 11 is a rectangular column with a length of 1 meter, a width of 1 meter, and a height of 1.2 meters. The top of pier block 11 is provided with first smoothing layer 13; Smoothing layer 14; the top surface of the first smoothing layer 13 is horizontal to the top surface of the second smoothing layer 14; the center of the first brick pier 11 and the center of the second brick pier 12 are 4.5 meters apart;

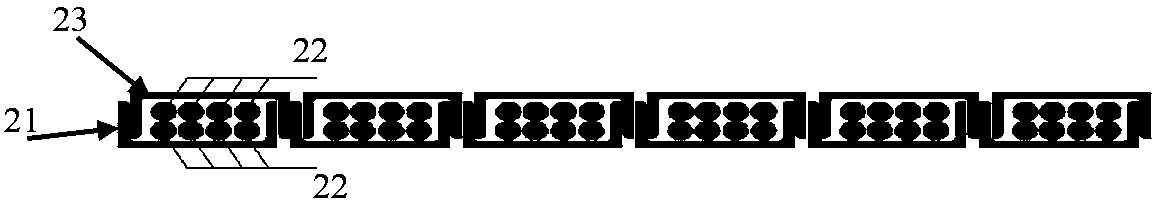

[0031] The preloaded load components are composed of preloaded load units, and the preloaded load components are composed of 2 to 10 preloaded load units arranged horizontally;

[0032] The preloaded load unit is approximately a rectangular block, and is composed...

Embodiment 2

[0036] see Figure 4 , used for the stacked preloaded structural parts of the tall formwork support system, including brick pier components and preloaded load components;

[0037] The brick pier assembly is composed of a first brick pier block 11 and a second brick pier block 12; wherein, the first brick pier block 11 is a rectangular column with a length of 1 meter, a width of 1 meter, and a height of 1.5 meters. The top of pier block 11 is provided with the first plastering layer 13; Smoothing layer 14; the top surface of the first smoothing layer 13 is horizontal to the top surface of the second smoothing layer 14; the center of the first brick pier 11 and the center of the second brick pier 12 are 4.5 meters apart;

[0038] The preloaded load components are composed of preloaded load units, and the preloaded load components are composed of six preloaded load units arranged horizontally;

[0039]The preloaded load unit is approximately a rectangular block, and is composed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com